Benefication method for sulphur-containing composite iron tailing

A beneficiation method and compound iron ore technology, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems that sulfur-containing compound iron ore tailings beneficiation technology has not been reported, and achieve the reduction of tailings discharge , ease tailings treatment and stacking, and improve the effect of mineral utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

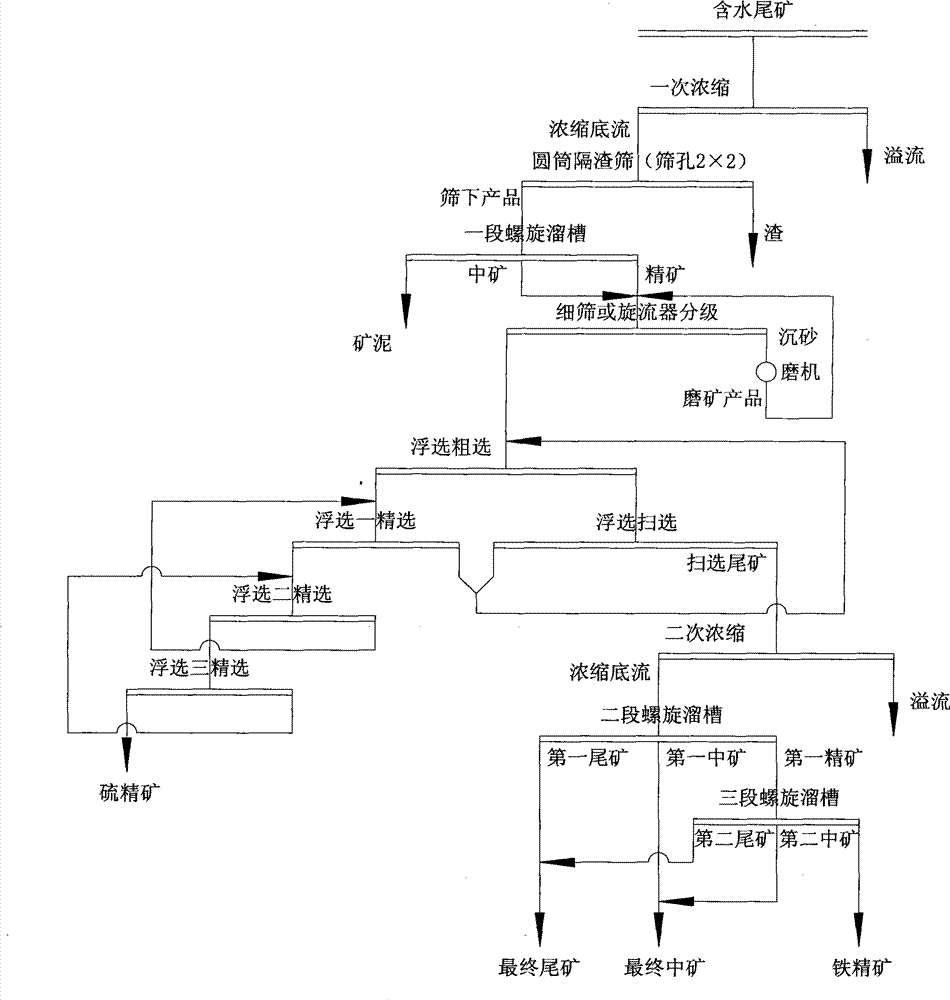

[0023] Please see figure 1 , figure 1 It is a process flow chart of the beneficiation method of sulfur-containing compound iron ore tailings. After the water-containing tailings are concentrated at the first stage, concentrated underflow and overflow are obtained. The concentration of the concentrated underflow is 25% to 35%, and the overflow suspended matter is lower than 200 mg / L, used as circulating water; the concentrated underflow passes through the slag separation of the cylindrical slag separation screen (the sieve diameter of the cylindrical slag separation sieve is 2×2mm), and the under-sieve product and slag of ≤2mm are obtained; the under-sieve product passes through a Graded spiral chute separation to obtain ore slime, middling ore, concentrate, middling ore and concentrate are combined for cyclone classification and concentration, and qualified particle size sand settling-200 mesh is separated, accounting for 70% to 80%, and the concentration is 15%. ~20%, the gr...

Embodiment 2

[0025] Embodiment 2: certain iron ore tailings iron grade 19% (wherein: hematite iron grade 7.8%, siderite iron grade 10%), sulfur grade 0.5%, Si0 2 Content 24%. In order to fully recover the useful components in the tailings, the present invention is achieved by designing a process flow of concentration-slag separation-gravity separation-classification-grinding-flotation-gravity separation to recover sulfur-containing iron tailings Iron concentrate, sulfur concentrate and other useful mineral components. First, the minerals are concentrated (concentrated underflow concentration 25% to 30%), slag separation treatment, and impurities in the sulfur-containing iron tailings are removed to create favorable conditions for sorting operations. Second, use spiral chute for desliming to obtain mixed concentrate and mud ore; use fine screen or hydrocyclone to classify (grading overflow-200 mesh accounts for 70% to 75%, concentration 18% to 20%), and obtain Coarse and fine grades of ma...

Embodiment 3

[0026] Embodiment 3: certain iron ore tailings iron grade 21% (wherein: hematite iron grade 9%, siderite iron grade 11%), sulfur grade 1%, SiO 2Content 20%. In order to fully recover the useful components in the tailings, the present invention is achieved by designing a process flow of concentration-slag separation-gravity separation-classification-grinding-flotation-gravity separation to recover sulfur-containing iron tailings Iron concentrate, sulfur concentrate and other useful mineral components. Firstly, the minerals are concentrated (concentrated underflow concentration 30% to 35%), slag separation treatment, and impurities in the sulfur-containing iron tailings are removed to create favorable conditions for the sorting operation. Second, use spiral chute for desliming to obtain mixed concentrate and mud ore; use fine screen or hydrocyclone to classify (grading overflow-200 mesh accounts for 75% to 80%, concentration 15% to 18%), and obtain Coarse and fine grades of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com