Anti-tail out automatic control system of hot continuous rolling thin strip steel

An automatic control system, a thin strip technology, applied in the direction of rolling force/roll gap control, etc., can solve problems such as untimely adjustment, and achieve the effect of solving untimely adjustment, improving adaptability, and reducing the incidence of tail flicks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

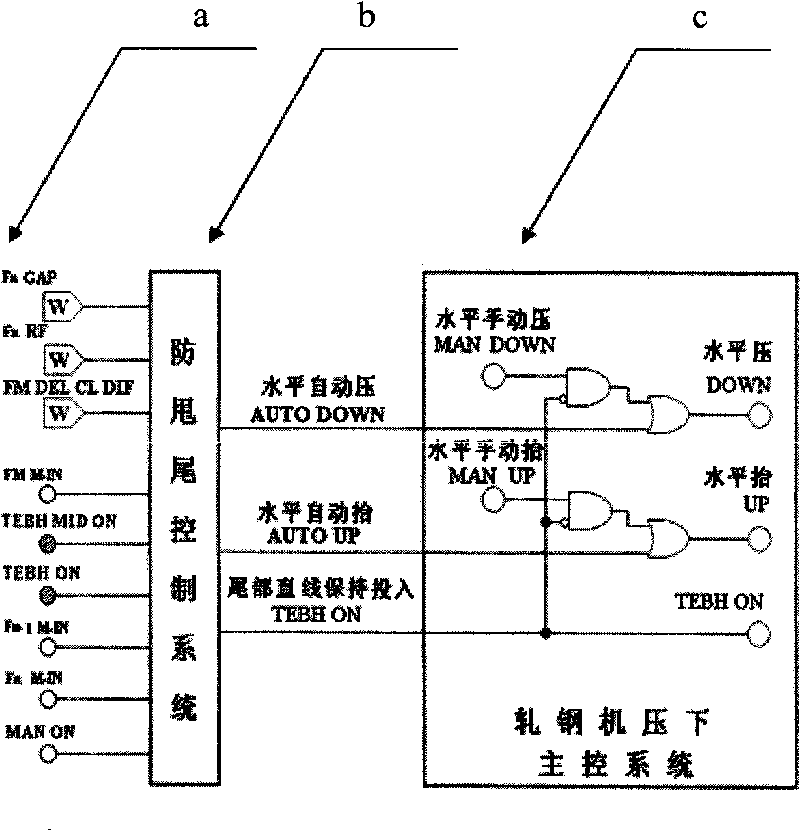

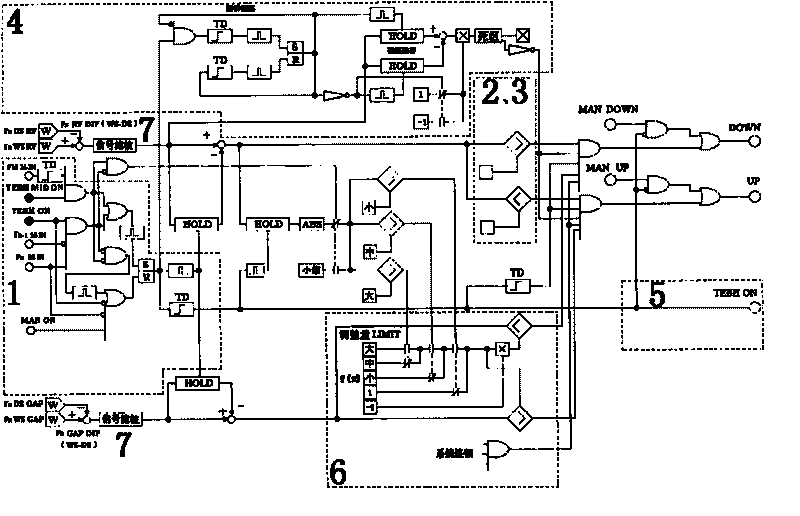

[0014] Such as figure 2 , image 3 As shown, the present invention can adopt the plug-in design independent of the original rolling mill control system, only need to take a small amount of detection signal a from the original rolling mill system, and apply the advanced PLC control platform b, the method is indirect but more reliable, and the cost Moderate, easy and convenient installation and commissioning, reliable work, and easy to expand functions.

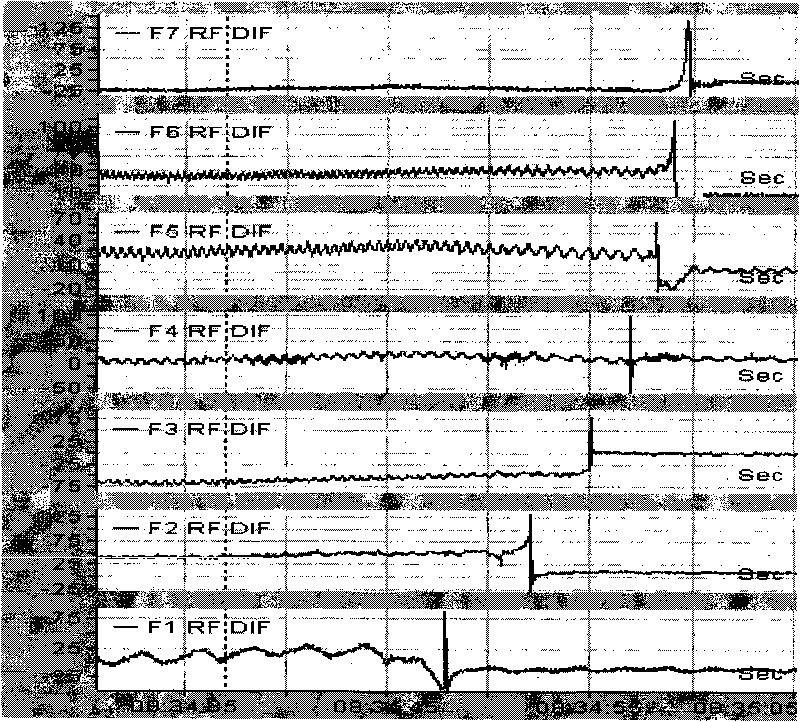

[0015] From figure 2 It can be seen from the figure that the PLC control platform b only takes the double-side rolling force signal Fn RF, the double-side roll gap signal Fn GAP and the center line deviation signal FMDEL CL DIF of each stand of the original rolling mill system, and a small amount of bit signal, including tail straight line hold function input selection TEBHON, tail straight line hold function middle inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com