Processing method for integrated Fiber Reinforced Plastic (FRP) mould of rail headstock

A fiberglass mold and processing method technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of poor mold quality, long construction period, high wood cost, etc., and achieve the effects of stable dimensional accuracy, short processing cycle, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Make a female mold

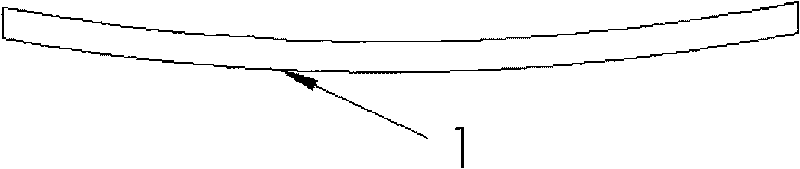

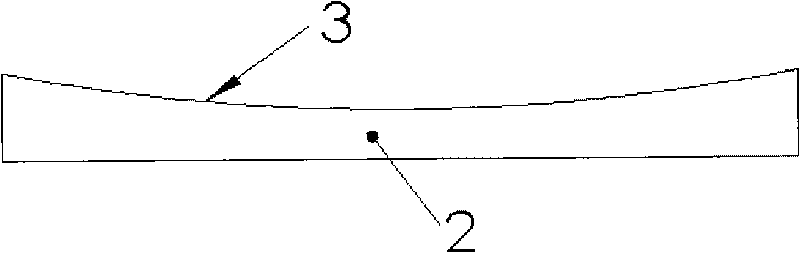

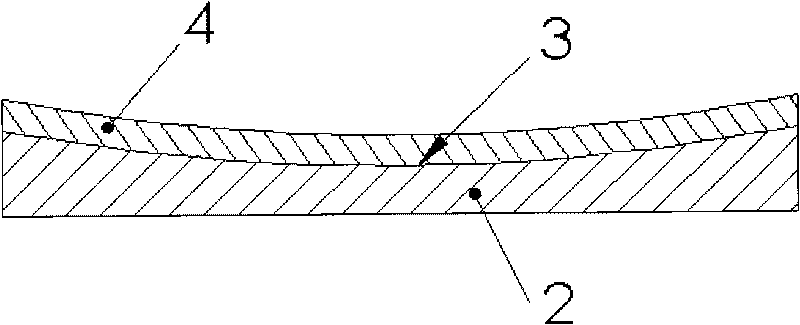

[0024] The female mold 2 is processed by numerical control, and the material of the female mold is a polystyrene foam board. The female model surface 3 is obtained by offsetting the mold surface 1 by 5-10mm, and this 5-10mm is used as the machining allowance of the mold after the male mold is pulled out. (see attached figure 1 with figure 2 )

[0025] 2. Paste model resin

[0026] Mix the epoxy resin (H6403A) and the curing agent (H6405-1B) at a ratio of 1:1 at normal temperature and pressure, and place them in a ventilated and dry place. The two will react chemically to obtain the paste model resin 4; The shape model resin 4 is evenly coated on the female mold 2 with a coating thickness of 40-60 mm, waiting for curing. The curing time varies slightly according to the season, generally 8 to 12 hours in winter and about 8 hours in summer. (see attached image 3 )

[0027] 3. Bonding steel skeleton

[0028] After the pasty model resin 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com