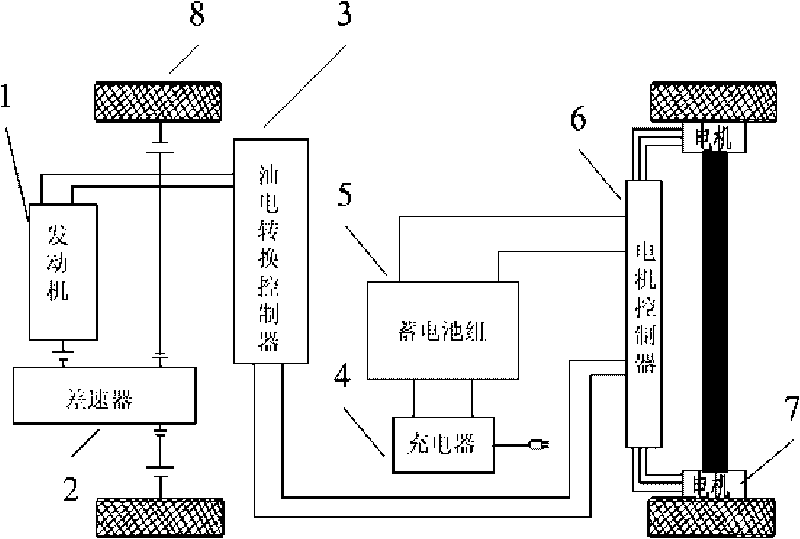

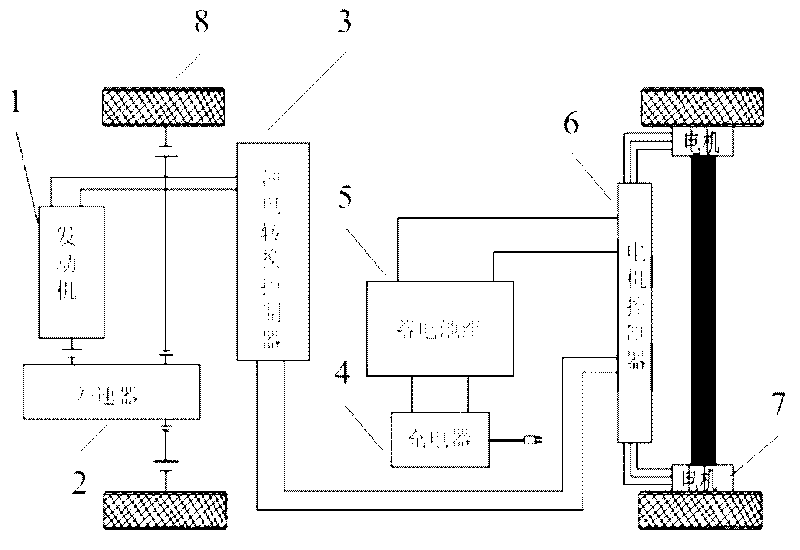

Chassis power transmission system structure of hybrid four-wheel vehicle

A power transmission system, hybrid technology, applied in hybrid vehicles, motor vehicles, power units, etc., to reduce pollution, save energy, and facilitate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Accompanying drawing is a schematic view of the structure of the present invention, in-wheel motor (7) is installed on the chassis rear axle among the figure, motor controller (6), storage battery pack (5), charger (4) is positioned at rear axle front, engine (1) adds The differential (2) assembly is connected with the front wheels (8), and the chassis also includes components such as vehicle frame structure, suspension system, braking system, wiring harness, and the like.

[0014] After the battery pack is fully charged by the on-board charger, start the gasoline-electric conversion switch and place it in the electric gear. By controlling the gasoline-electric integrated accelerator to drive the motor control system, the two hub motors of the rear wheels are driven forward and backward, thereby driving the vehicle forward and backward. When the power is insufficient, put the fuel-electric switch in the engine gear, start the ultra-micro engine system to drive the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com