Method for preparing chamigrenal from shizandra

A technology of chamilaldehyde and schisandra, which is applied in the separation/purification of carbonyl compounds, bulk chemical production, organic chemistry, etc., and can solve the problems of low active ingredient content, backward technology and equipment, and unstable quality of schisandra extract , to avoid oxidation or thermal decomposition, high purity, compact operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

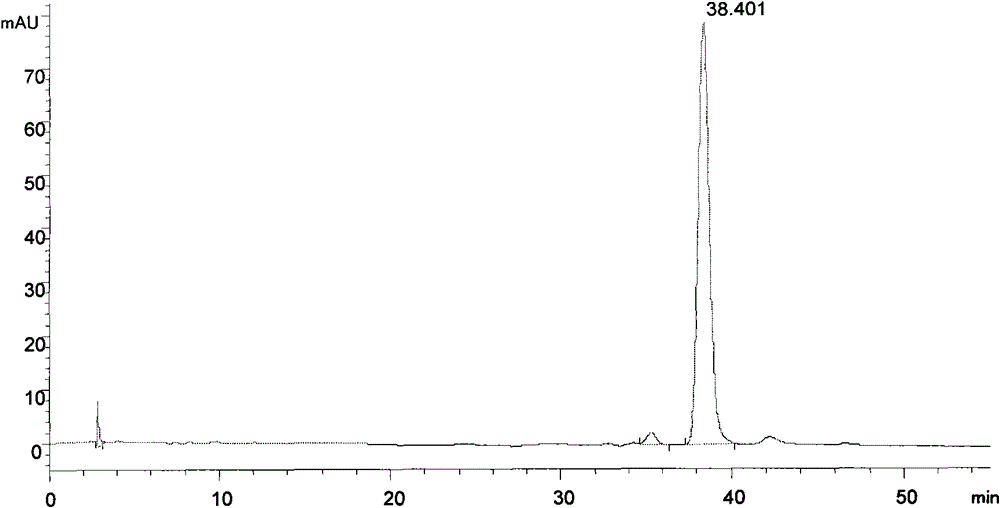

[0018] Put 300g of pulverized Schisandra powder into a 1L extraction kettle, and put the whole extraction system with CO 2 Replace and fill. Set extraction unit parameters, CO 2 The flow rate is 20L / h; the extraction pressure is 25MPa and the temperature is 45°C; the pressure of the primary separator is 8MPa and the temperature is 35°C; the pressure of the secondary separator is 6MPa and the temperature is 40°C. After continuous dynamic extraction for 4 hours, the obtained product was a yellow oil with the unique fragrance of Schisandra chinensis. The extract was weighed, 33.6g in total, and the extraction yield was 11.2%.

Embodiment 2

[0020] Put 300g of pulverized Schisandra powder into a 1L extraction kettle, and put the whole extraction system with CO 2 Replace and fill. Set extraction unit parameters, CO 2 The flow rate is 20L / h; the extraction pressure is 20MPa and the temperature is 38°C; the primary separation pressure is 8MPa and the temperature is 35°C; the secondary separation pressure is 6MPa and the temperature is 40°C. After continuous dynamic extraction for 4 hours, the yellow oily extract was collected from the bottom of the separator, totaling 27.0 g, and the extraction yield was 9.0%.

Embodiment 3

[0022] Put 300g of pulverized Schisandra powder into a 1L extraction kettle, and put the whole extraction system with CO 2 Replace and fill. Set extraction unit parameters, CO 2 The flow rate is 15L / h; the extraction pressure is 23MPa and the temperature is 38°C; the primary separation pressure is 8MPa and the temperature is 35°C; the secondary separation pressure is 6MPa and the temperature is 40°C. After continuous dynamic extraction for 5 hours, the yellow oily extract was collected from the bottom of the separator, totaling 30.3 g, and the extraction yield was 10.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com