Continuous-flow and ultrasonic-wave light biological hydrogen producing reactor

A hydrogen production reactor and ultrasonic technology, which is applied in photobioreactors, gas production bioreactors, biochemical instruments, etc., can solve the problems of low hydrogen production rate and cell membrane thickness, and achieve the improvement of metabolic function and enzyme activity. , the effect of increasing the ability of bacterial growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

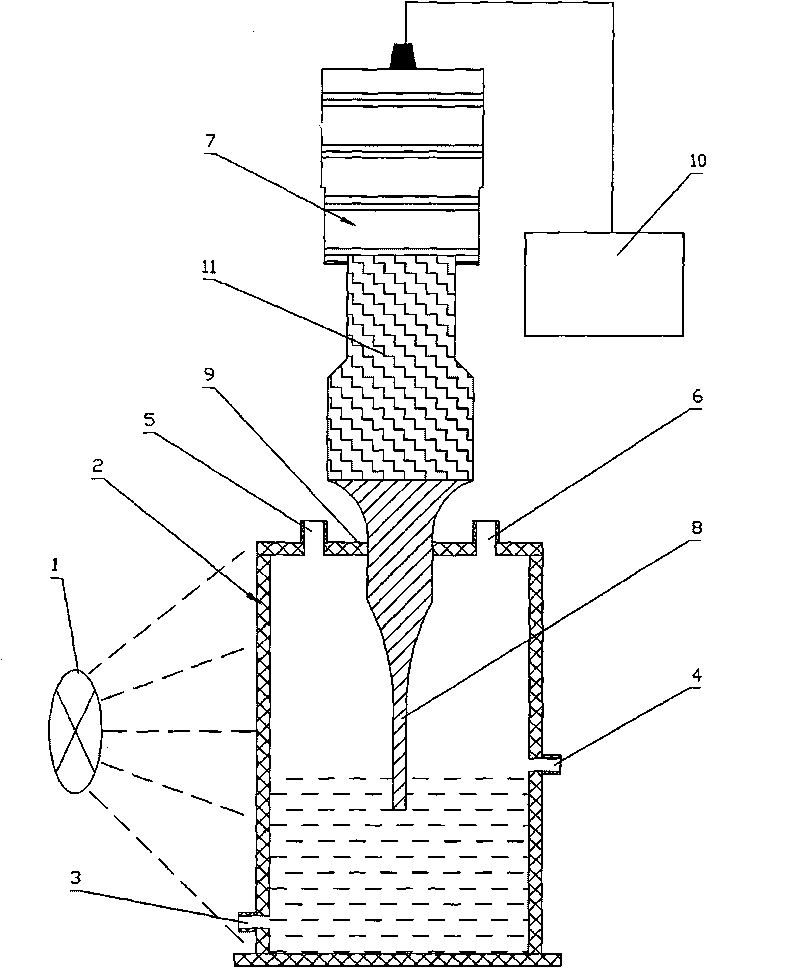

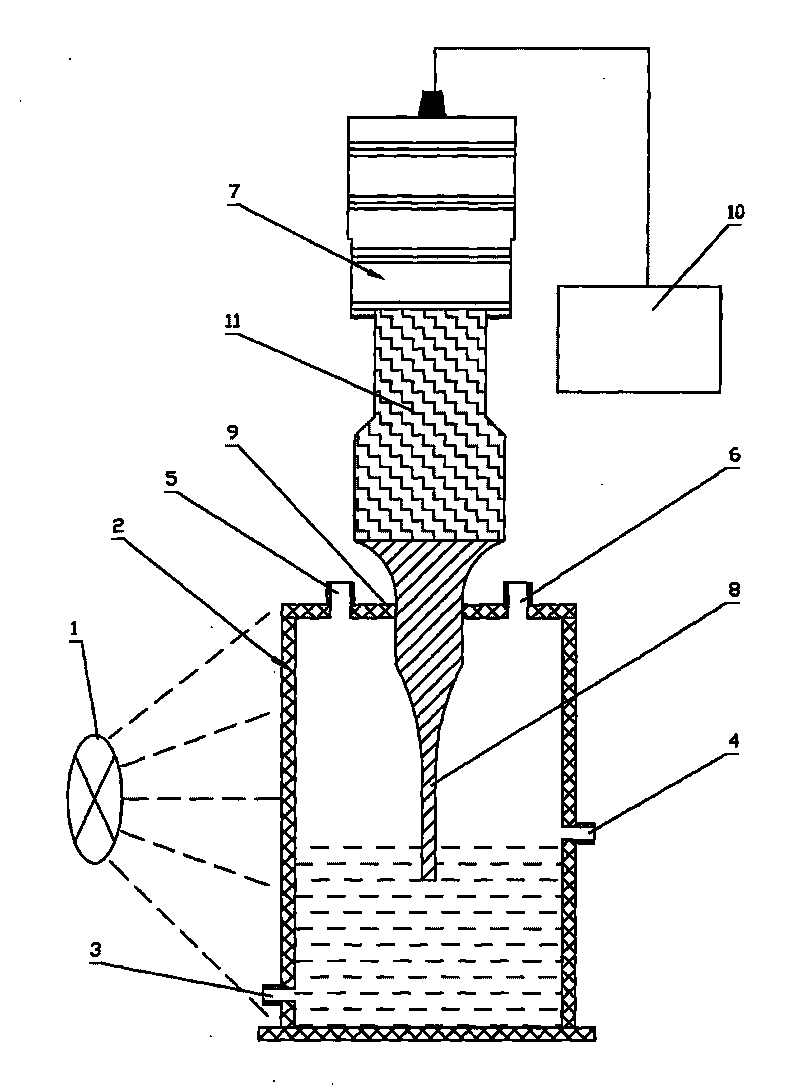

[0015] The accompanying drawing is a schematic structural diagram of the present invention, as shown in the figure: the continuous flow ultrasonic photobiological hydrogen production reactor includes a light source 1 , a transparent box 2 illuminated by the light source 1 and an ultrasonic cell pulverizer 7 . The bottom of the transparent box body 2 is provided with a liquid inlet 3, and the other side opposite to the liquid inlet 3 is provided with a liquid outlet 4, the height of the liquid outlet 4 is higher than the liquid inlet 3, and the top of the transparent box body 2 The upper cover 9 is provided with an air inlet 5 and an air outlet 6 . The ultrasonic cell pulverizer 7 includes a control host 10, a transducer 11 and a horn 8. Since the structure of the ultrasonic cell pulverizer 7 is a prior art, it will not be repeated her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com