Method for synthesizing amorphous nickel-cobalt alloy nano-film loaded with platinum particles

A technology of amorphous nickel and nano-film, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve good electrochemical performance, convenient and simple product processing, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

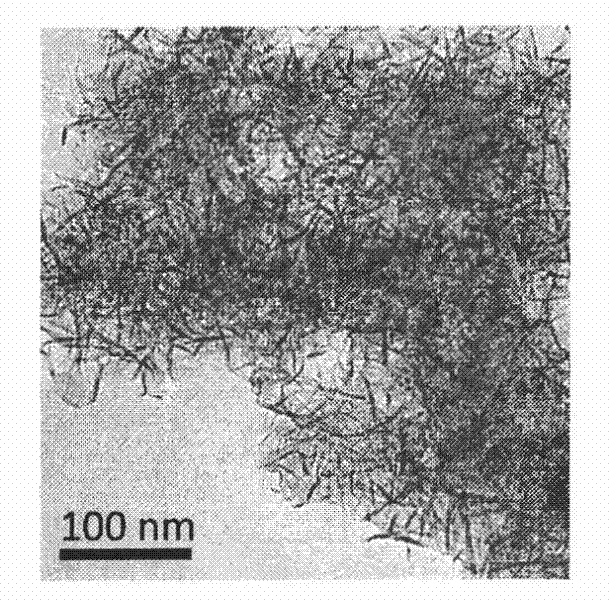

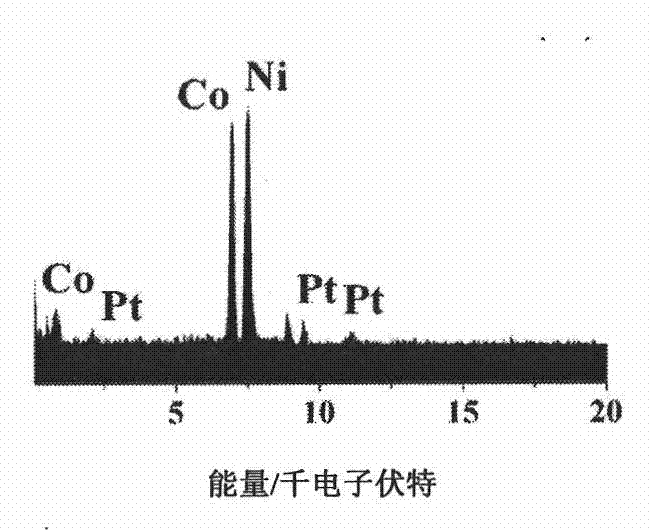

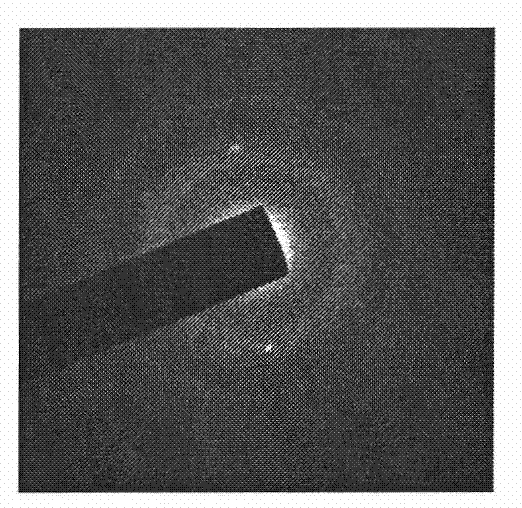

[0048] Example 1 Ni 47.5 co 47.5 Pt 5 Amorphous Nickel-Cobalt Alloy Nanofilms Supporting Platinum Particles

[0049] The first step is to use the method of manual film making, add 5-10mL collodion solution into a 100mL beaker, tilt the beaker, slowly spread the collodion solution evenly on the bottom and side walls of the beaker, and invert the beaker for about 3-5 minutes It is air-dried naturally, the film is peeled off, and it is set aside.

[0050] The second step, accurately weigh 5.65mg of NiCl 2 ·6H 2 O, 5.65mg of CoCl 2 ·6H 2 O and 1.30 mg H 2 PtCl 6 ·6H 2 Put O in a beaker, add 10ml of deionized water, stir well to dissolve it, and configure it as Ni 47.5 co 47.5 Pt 5 aqueous solution.

[0051] Step 3: Accurately weigh 26.97mg of KBH 4 Put it in a beaker, add 10ml of deionized water, stir well to dissolve it, and configure it into 0.05mol / L KBH 4 Solution, add 3-5 drops of 0.2mol / L NaOH solution to adjust its pH value to 10-12.

[0052] The fourth step...

Embodiment 2

[0054] Example 2 Ni 40 co 40 Pt 20 Amorphous Nickel-Cobalt Alloy Nanofilms Supporting Platinum Particles

[0055] The first step is to use the method of manual film making, add 5-10mL collodion solution into a 100mL beaker, tilt the beaker, slowly spread the collodion solution evenly on the bottom and side walls of the beaker, and invert the beaker for about 3-5 minutes It is air-dried naturally, the film is peeled off, and it is set aside.

[0056] The second step, accurately weigh 4.75mg NiCl 2 ·6H 2 O, 4.75mg CoCl 2 ·6H 2 O and 5.18 mg H 2 PtCl 6 ·6H 2 Put O in a beaker, add 10ml of deionized water, stir well to dissolve it, and configure it as Ni 40 co 40 Pt 20 aqueous solution.

[0057] Step 3: Accurately weigh 26.97mg of KBH 4 Put it in a beaker, add 10ml of deionized water, stir well to dissolve it, and configure it as 0.05mol / L KBH 4 Solution, add 3-5 drops of 0.2mol / L NaOH solution to adjust its pH value to 10-12.

[0058] The fourth step, the Ni 40 c...

Embodiment 3

[0060] Example 3 Ni 25 co 25 Pt 50 Amorphous Nickel-Cobalt Alloy Nanofilms Supporting Platinum Particles

[0061] The first step is to use the method of manual film making, add 5-10mL collodion solution into a 100mL beaker, tilt the beaker, slowly spread the collodion solution evenly on the bottom and side walls of the beaker, and invert the beaker for about 3-5 minutes It is air-dried naturally, the film is peeled off, and it is set aside.

[0062] The second step, accurately weigh 2.97mg NiCl 2 ·6H 2 O, 2.97mg CoCl 2 ·6H 2 O and 12.95 mg H 2 PtCl 6 Put it in a beaker, add 10ml of deionized water, stir well to dissolve it, and configure it as Ni 25 co 25 Pt 50 aqueous solution.

[0063] The third step, accurately weigh 26.97mg KBH 4 Put it in a beaker, add 10ml of deionized water, stir well to dissolve it, and configure it as 0.05mol / L KBH 4 Solution, add a certain amount of 0.2mol / L NaOH solution to adjust its pH value to 10-12.

[0064] In the fourth step, 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com