Magnesium alloy corrosion inhibitor and preparation method thereof

A corrosion inhibitor and magnesium alloy technology, which is applied in the coating process of metal materials, etc., can solve the problems of serious environmental pollution, complex synthesis process, and low corrosion inhibition efficiency, and achieve high corrosion inhibition efficiency, less dosage, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of magnesium alloy corrosion inhibitor:

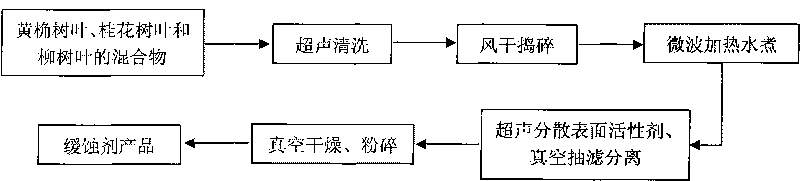

[0025] The technological process of its preparation method sees figure 1 ,details as follows:

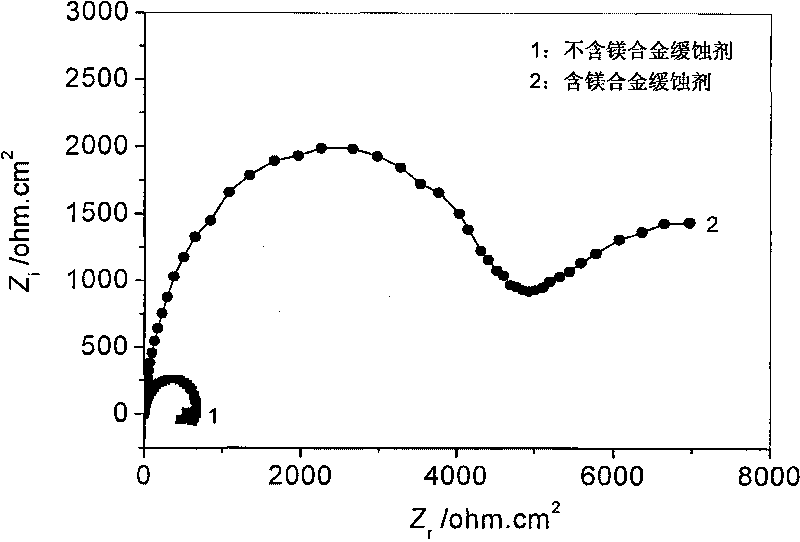

[0026] Pour the mixture 800g of fresh Jujube leaves (weight fraction 16%), sweet-scented osmanthus leaves (weight fraction 53%) and willow leaves (weight fraction 31%) into cleaning decontamination in the ultrasonic cleaning machine that about 8L pure water is housed, cleaning temperature at 35°C for 11 minutes; then air-dried and mashed for 43 minutes on an air-drying masher; then put it into a special container for microwave heating, add about 9L of pure water to the container, and boil it with microwave heating to control the temperature The temperature is 90°C, and the time is 270 minutes; ultrasonically disperse N-oleoyl N-methyl taurate sodium in the boiled mixture, and the amount of N-oleoyl N-methyl taurate added is the weight of the mixture 0.16%; then, carry out vacuum filtration and separation; place the f...

Embodiment 2

[0041] ① Preparation of magnesium alloy corrosion inhibitor:

[0042] The technological process of its preparation method sees figure 1 ,details as follows:

[0043] Pour the mixture 500g of fresh Jujube leaves (weight fraction 11%), osmanthus osmanthus leaves (weight fraction 67%), willow leaves (weight fraction 22%) into the ultrasonic cleaning machine that about 5L pure water is housed to clean and decontaminate, cleaning temperature at 32°C for 10 minutes; then air-dry and mash for 40 minutes on an air-drying masher; The temperature is 92°C, and the time is 210 minutes; ultrasonically disperse sodium oleoyloxyethanesulfonate in the boiled mixed solution, and the amount of sodium oleoyloxyethanesulfonate added is 0.12% of the weight of the mixed solution; then, carry out Vacuum filtration and separation; place the filtrate in a drying oven, vacuum-dry at 52°C for 290 minutes, and pulverize after drying to obtain the corrosion inhibitor product.

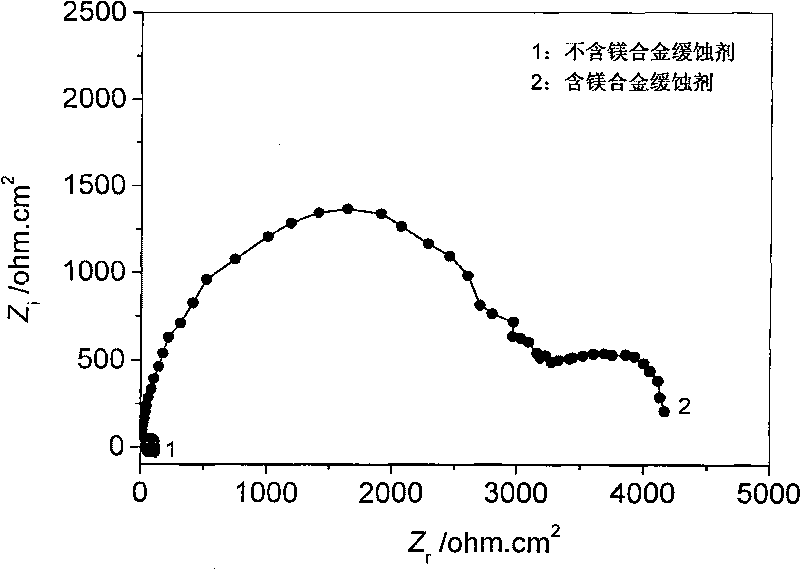

[0044] ②Evaluation of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com