Method for encapsulating optical fiber Bragg grating temperature sensor

A temperature sensor, fiber Bragg technology, used in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve problems such as temperature sensor damage, and achieve the effects of simple structure, good stability, and improved response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

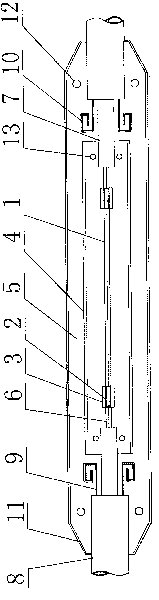

[0012] Peel off the 5mm coating layer on both sides of the grating area of the fiber grating 1 to expose the bare optical fiber, and clean it with acetone. Use a fusion splicer to weld the two ends of the fiber grating 1 to the two ends of the optical fiber in the optical cable. The fiber grating 1 is fixed on the fixing point 3 of the grooved metal strip 4, the grooved metal strip 4 is 30cm in length and is made of stainless steel sheet. The optical fiber grating 1 and the pigtail 6 are in a relaxed state, the bonding points at both ends of the grooved metal strip 4 are glued to the optical fiber, and the optical cable armoring layer 7 is fixed on the grooved metal strip 4 with the optical cable armoring layer fixing bolts 13, Fill the gap with heat-conducting silicone grease 5; place the above-mentioned encapsulated grooved metal strip 4 in a stainless steel package shell 11 with a length of 40 cm, and press the steel wire 9 in the transmission optical cable 8 into the symm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com