Method for measuring graphite oven atomic absorption spectrum of arsenic element in steel

A technology of graphite furnace atomic and absorption spectroscopy, which is applied in the detection field of raw materials and finished products, can solve the problems of poor quantitative analysis accuracy, background interference, chemical interference, etc., and achieve the effect of improving stability and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

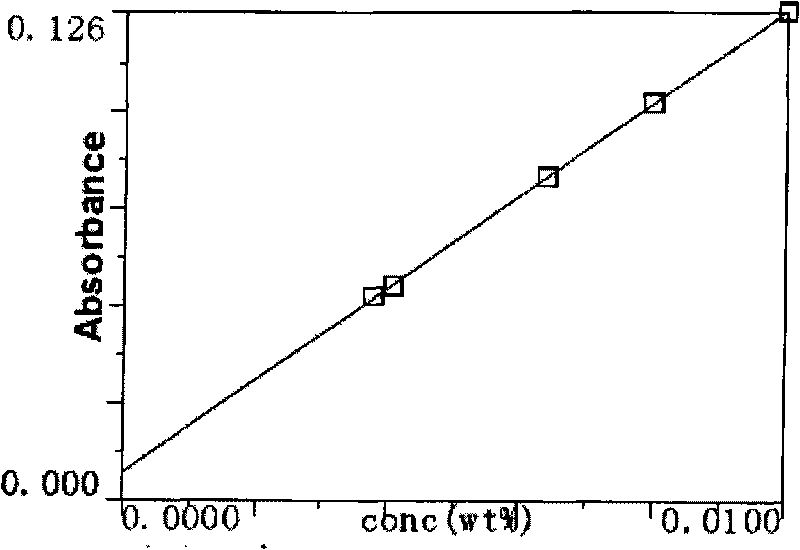

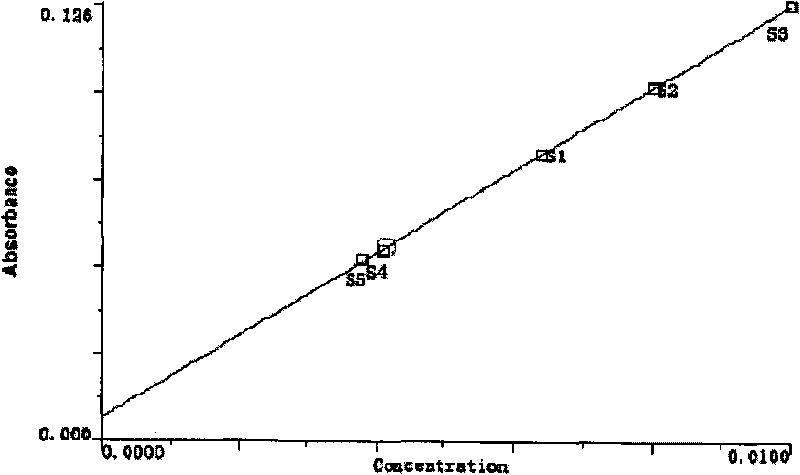

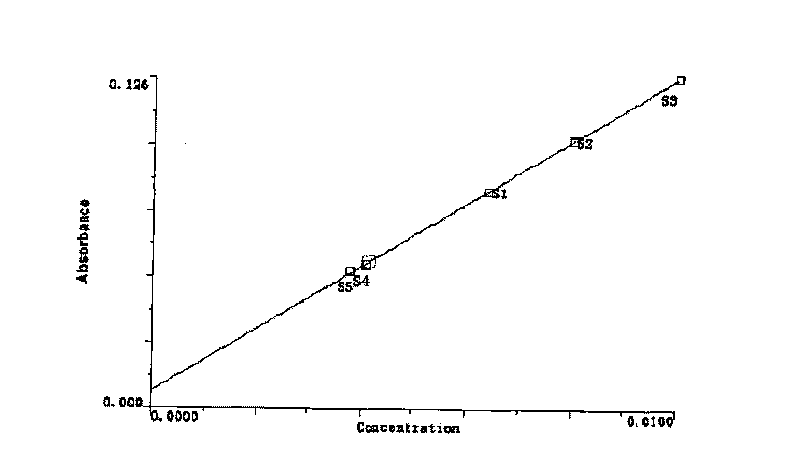

Image

Examples

Embodiment

[0040]1. Experimental conditions. Use a Zeeman graphite furnace atomic absorption spectrometer, an electrodeless discharge lamp as a light source, a platform graphite tube, and nitric acid to be prepared in a weight ratio of concentrated nitric acid: water=1:3.

[0041] 2. Sampling. Weigh 0.1000 g of chip steel sample.

[0042] 3. The sample dissolves. Weigh 0.1000 g of steel sample and put it into a 100 ℃ quartz beaker, add 5.00 ml of nitric acid of this concentration, heat to dissolve at a low temperature less than 300°C, remove nitrogen oxides in the steel sample, and wait until the sample is completely dissolved Afterwards, remove and cool to room temperature; transfer the dissolved sample to a 100ml volumetric flask, add deionized water to dilute to the mark, shake well, and wait for the test.

[0043] 4. Dissolve the standard sample series according to the above analysis steps (determined according to the concentration of arsenic, such as 0.0038%, 0.0064%, 0.0080% and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com