Dry vertical shaft storage system for spent fuel of nuclear power station and storage method thereof

A spent fuel and nuclear power plant technology, applied to the spent fuel storage system of pebble bed high-temperature gas-cooled reactor nuclear power plant and its storage field, to prevent the impact of external events, reduce the amount of three wastes, and reduce the effect of initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

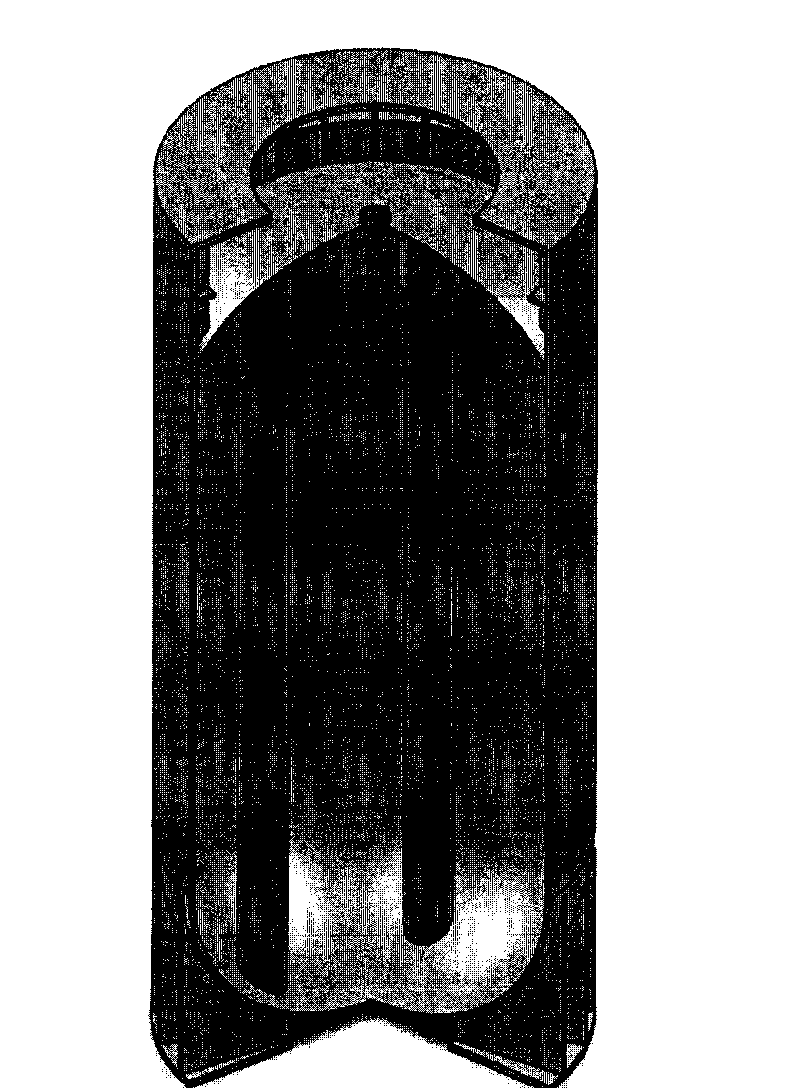

[0051] figure 1 It is a schematic diagram of a spent fuel storage tank of a dry shaft storage system for nuclear power plant spent fuel according to the present invention, and the spent fuel is stored in the spent fuel storage tank. The spent fuel storage tank is a thin-walled bare tank. The height of the tank is about 4m, and the outer diameter is about 1.8m. It can be put into the shielded transfer container of spent fuel as a whole to facilitate the transfer of spent fuel. The top of the spent fuel storage tank is equipped with a hoisting port, through which the hoisting of the spent fuel storage tank can be remotely controlled and monitored in real time, and the hois...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com