High-efficiency and energy-saving wet dust collector

A wet dust collector, high-efficiency and energy-saving technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agent, etc., can solve the problems of single dust removal, high energy consumption, high cost, etc., to improve dust removal efficiency, improve living environment, The effect of structural tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

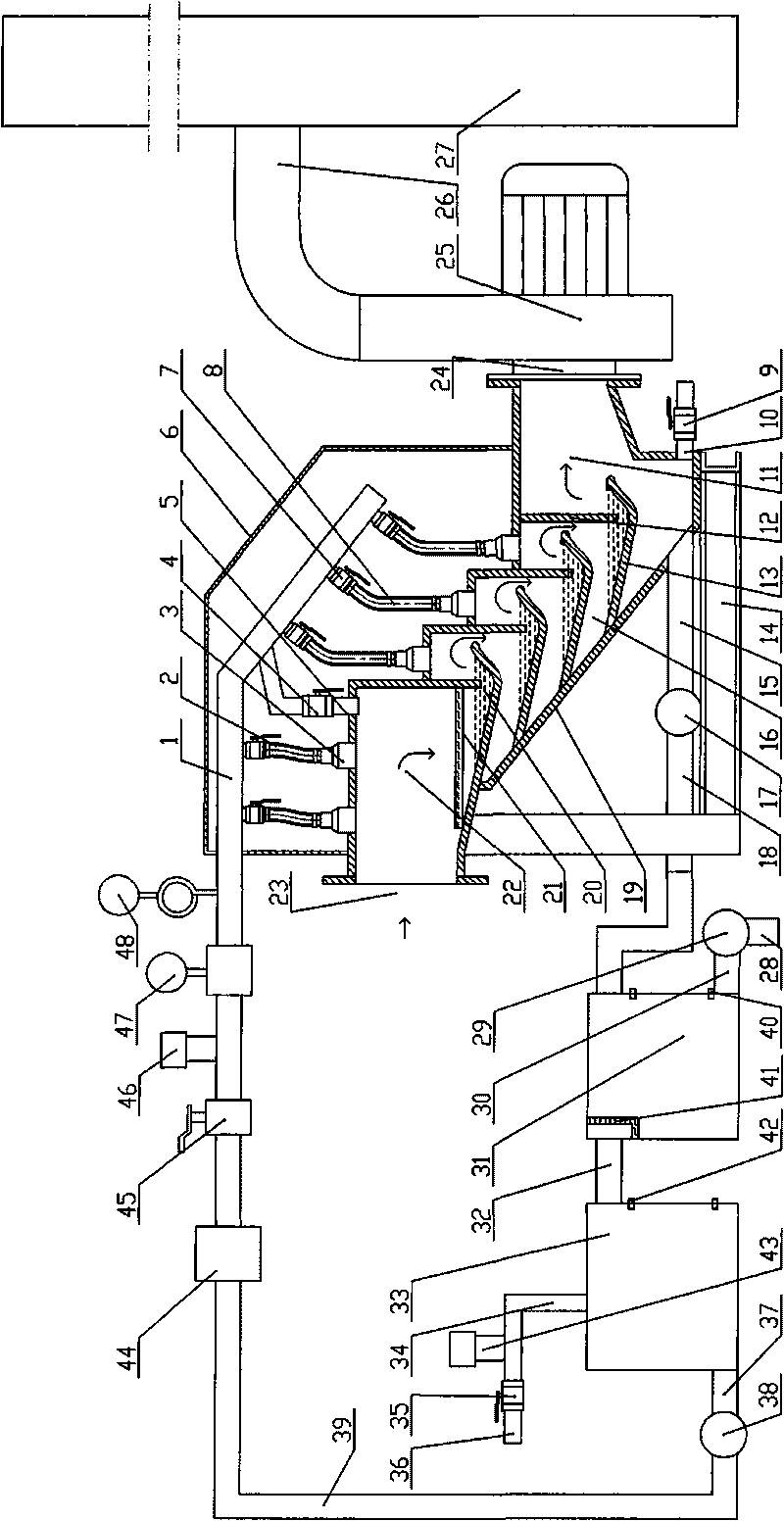

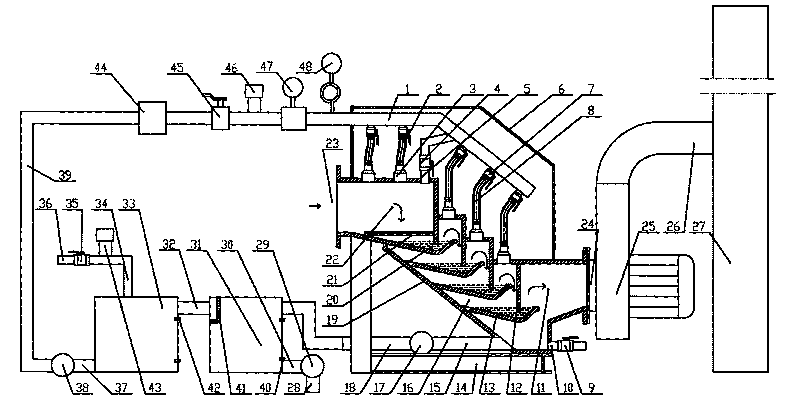

[0009] Specific implementation mode one: (see figure 1 ) The present embodiment is made up of casing 19 with inlet and outlet, more than one dust removal plate 12, more than one water tank 13, dust removal plate 12 and water tank 13 are supporting, several spray nozzles 3, dust removal net 21, various The water retaining plate of form, some rubber hoses 8 some, some valves 7, air volume control valve, induced draft fan 25, chimney 27, upper cover 6, blowdown valve 9, tank connecting pipe form. The dust removal plate 12 and the water tank 13 are connected with the inner wall of the casing 19 . The box is divided into several chambers, namely the inlet dust removal chamber 22, the closed dust removal chamber 16 (the number is determined by the number of groups of dust removal plates 12 and water tanks 13), the outlet dust removal chamber 11, and the spray nozzle 3. The chamber is connected with the box body 19 , the other end is connected with the valve 7 and the water supply p...

specific Embodiment approach 2

[0010] Specific implementation mode two: (see figure 1 ) The difference between this embodiment and the specific embodiment one is that it has increased the water circulation setting, the mortar pump 17, the still water pool 31, the clear water pool 33, the sewage pump 29, the clear water pump 38, the filter screen 41, the water level gauge 42, the sludge Height detector 40, solenoid valve 43, water filter 44, solenoid valve 46, flowmeter 47, pressure gauge 48. The mortar pump 17 and the water inlet pipe 15 communicate with the bottom of the casing 19, the outlet of the mortar pump 17 communicates with the still water pool 31, the sludge height detector 40 is fixed on the wall of the still water pool 31, and the water inlet pipe 30 of the sewage pump 29 It communicates with the bottom of the static water pool 31, and the outlet pipe 28 of the sewage pump 29 is connected to the nearby belt to recycle the sludge. No secondary pollution. The top of the still water pool 31 is pr...

specific Embodiment approach 3

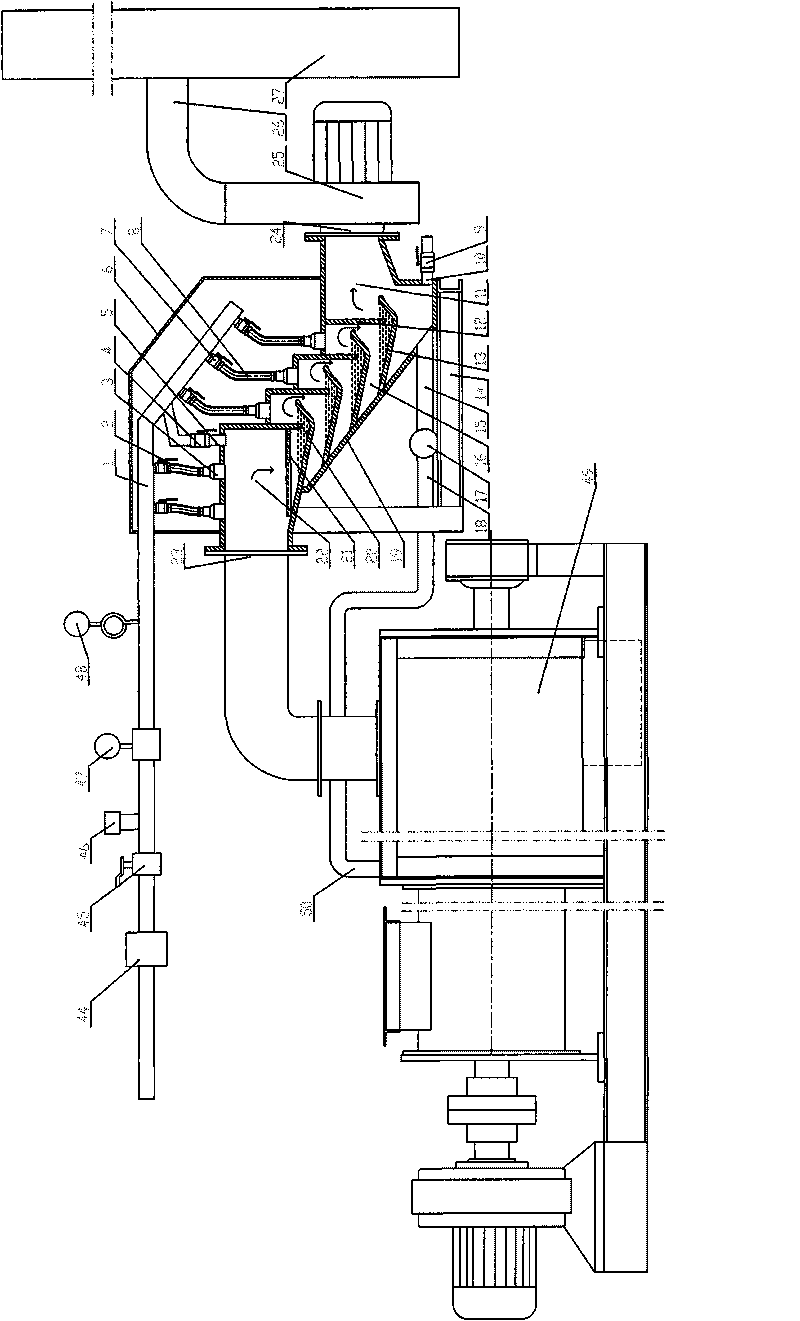

[0011] Specific implementation mode three: (see Figure II ) This dust collector is suitable for all kinds of dust. It is used for different dust removal, and its water circulation system is also different. If it is used for quicklime digestion and dedusting, its cycle setting must be changed, and all the mortar after dedusting will be used without secondary pollution. The difference from the second embodiment is that it omits the still water pool 31, the clean water pool 33 and the auxiliary facilities related thereto. The outlet pipe of the mortar pump 17 communicates with the water supply pipe 50 of the quicklime digester 49 . The dust removal water supply pipe 1 communicates with the water source pipe 36 through a pressure gauge 48, a flow meter 47, an electromagnetic valve 46, a valve 45, and a filter 46. Others are the same as the first embodiment.

[0012] Working process: Since this dust collector can remove many kinds of dust, its working process is also different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com