Bearing system of printing machine and printing machine thereof

A technology for printing machines and bearings, which is applied to printing machines, general parts of printing machinery, rotary printing machines, etc., and can solve problems such as adverse effects on printing quality and increased radial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

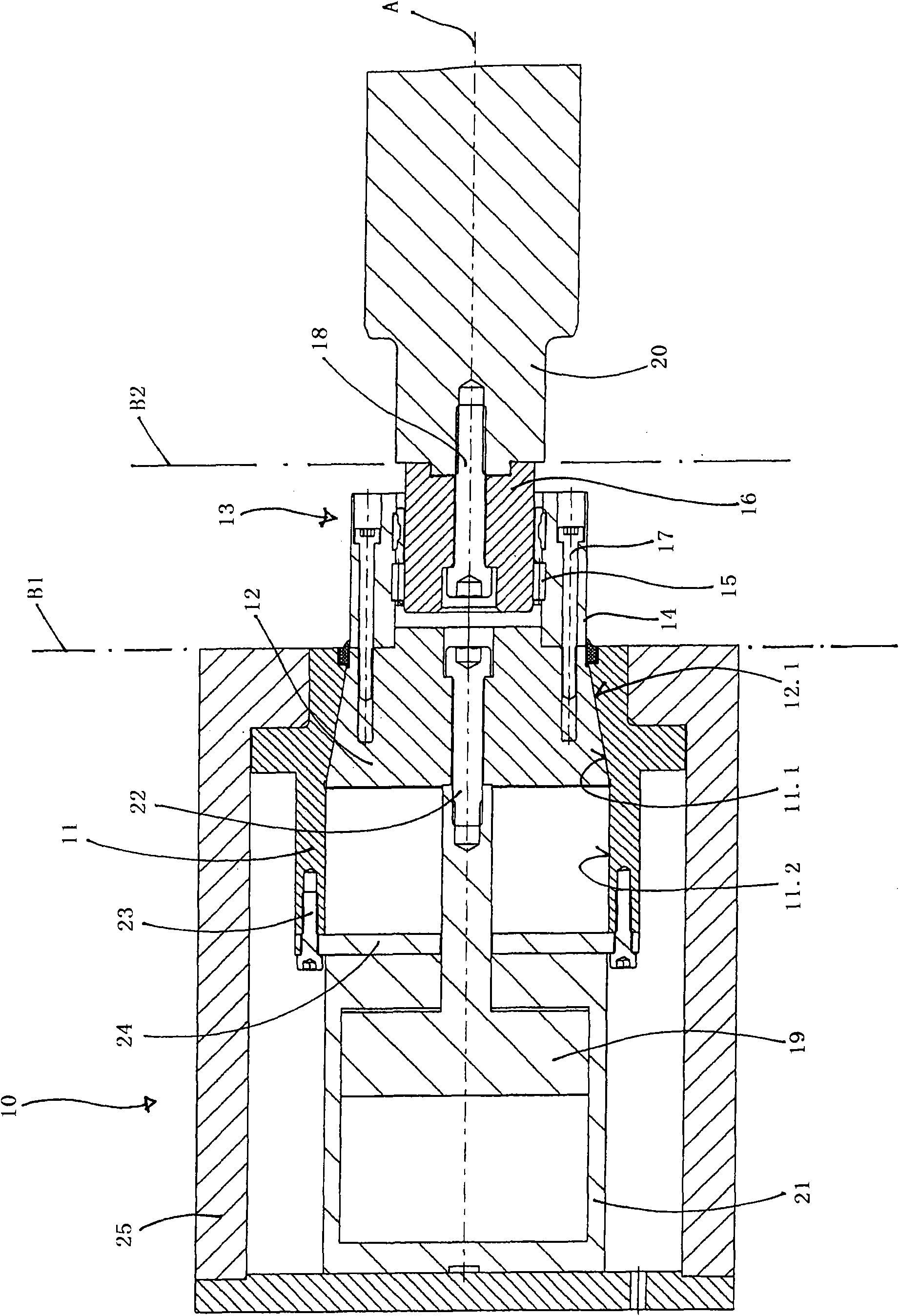

[0019] From this longitudinal section, firstly a bearing system 10 can be seen, which comprises a first housing part 11 and a second housing part 12 guided axially in the first housing part 11 . The two housing parts 11 , 12 have, corresponding to one another, conically extending circumferential regions 11 . 1 , 12 . 1 for forming the axial joint. On the conically distributed inner peripheral region 11.1 of the first housing part 11, a cylindrical inner peripheral region 11.2 is attached, which surrounds a cavity which, when a suitable force is applied, can push the second housing part 12 is pulled back into the cavity. The force is applied by means of a pneumatically actuatable piston 19 which is rigidly connected via a piston rod to the second housing part 12 and which is accommodated in a piston housing 21 which in turn is fixed to the first housing part 11 connect. Here, the piston housing has a radially protruding end plate 24 in which bores are provided for receiving f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com