Aeration biological filter bed and sewage advanced treatment method thereof

A technology of aerated biological filter bed and microporous aerator, which is applied in the field of water treatment, can solve the problems of biofilm aerated filter clogging, etc., and achieve the effects of high processing load, long service life and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

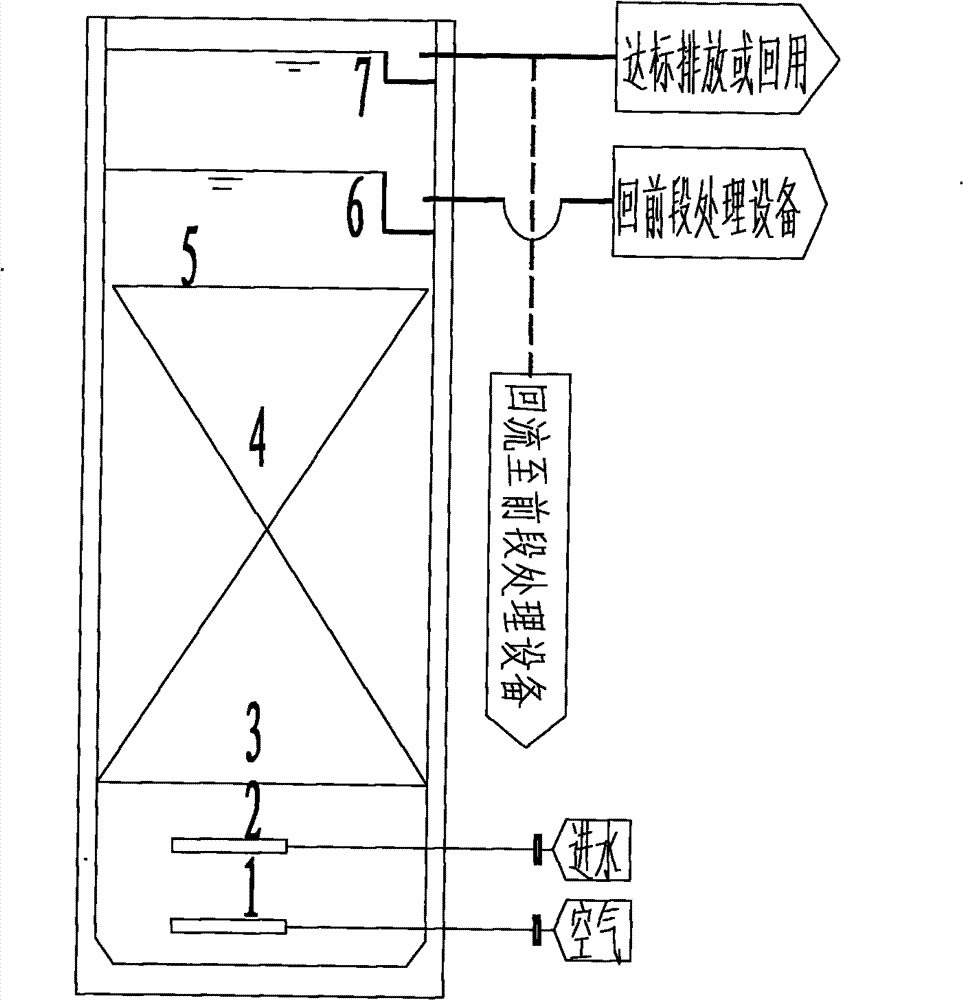

Image

Examples

Embodiment 1

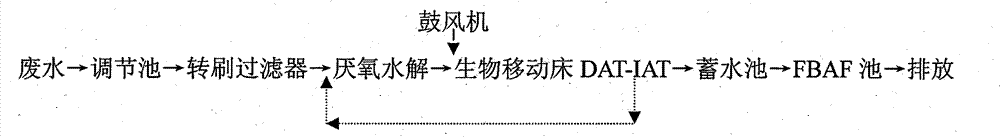

[0051] A certain aquatic product processing wastewater, with a treatment volume of 120t / d, adopts the following process:

[0052]

[0053] Raw water quality: COD≤2000mg / L, BOD≤800mg / L, SS≤350mg / L, TN≤60mg / L, TP≤8mg / L Oily substances: 80mg / L

[0054] FBAF influent water quality is COD≤300mg / L, BOD≤80mg / L, NH 3 ≤20mg / L, SS≤200mg / L, effluent requires COD≤100mg / L BOD≤30mg / L SS≤70mg / L TN≤20mg / L, FBAF equipment adopts modified HH-FBMP filler, which has a huge specific surface area, Can reach 80000m 2 / m 3 , after modification, microorganisms are easy to attach and grow, and can effectively remove COD and NH 4 + -N. Aeration is required for this equipment to operate. Effectively remove the remaining COD and NH after passing through this equipment 4 + -N. The diameter of the equipment is 1.2 meters, the height is 4.5 meters, and the thickness of the packing is 1.8 meters. The equipment is made of polymer materials for corrosion protection. Design pool capacity load 20kgCO...

Embodiment 2

[0057] A certain aquatic wastewater, the effluent from the biochemical tank directly enters this equipment, the FBAF equipment adopts our modified HH-FBMP filler, the thickness is 3 meters, the daily treatment capacity is 200t / d, the air-water ratio is adjusted to 6:1, there is no backflow, and the film is formed naturally During the period (the 3rd day after the system was started), the influent COD was 450mg / l. After two cycles of circulation treatment, the effluent detected COD 97mg / L, suspended solids: 8mg / L, and after one week of operation, the effluent reached COD 37mg / L, suspended solids: 8mg / L L, the effluent fully meets the first-level discharge standard in the "Comprehensive Sewage Discharge Standard GB8978-98", the suspended solids in the effluent meet the reuse standard, and meet the first-level A discharge standard in the "Pollutant Discharge Standard for Urban Sewage Treatment Plant GB18918-2002", To achieve the purpose and requirements of sewage treatment resourc...

Embodiment 3

[0059] A certain paint wastewater, the effluent from the biochemical pool directly enters this equipment, the daily treatment capacity is 2t / d, the air-water ratio is adjusted to 10:1, the return flow can be increased first and then decreased, and gradually decreased from 100% to 50%. The FBAF equipment adopts our Modified HH-FBMPHEA filler, the thickness of the filler is 5 meters, the commissioning is completed and started, after 10 days of operation, the influent COD is 860mg / l, the treated effluent COD is 95mg / L, and the suspended matter is less than 10mg / L, which meets the "Comprehensive Wastewater Discharge Standard GB8978-98" The medium-level discharge standard, the suspended solids in the effluent meet the reuse standard. No backwashing once. It was originally planned that the equipment should be backwashed every 2 days, the amount of backwashed gas should be increased by 3 times, the amount of water should be doubled, and the backwashed water will enter the biochemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com