Honeycomb network pipe bio-carrier

A bio-carrier and honeycomb network technology, applied in the field of water treatment, can solve the problems of slow film-hanging speed, less film-hanging amount, and low mass transfer efficiency in the biological carrier area, so as to increase the film-hanging speed and film-hanging amount, and improve the adhesion Effect of capacity, high volume load and handling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

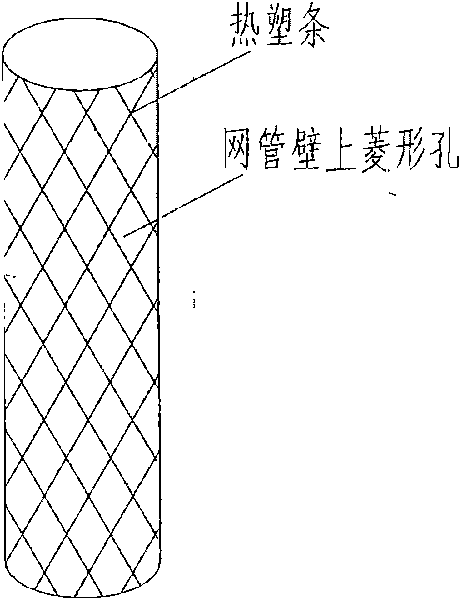

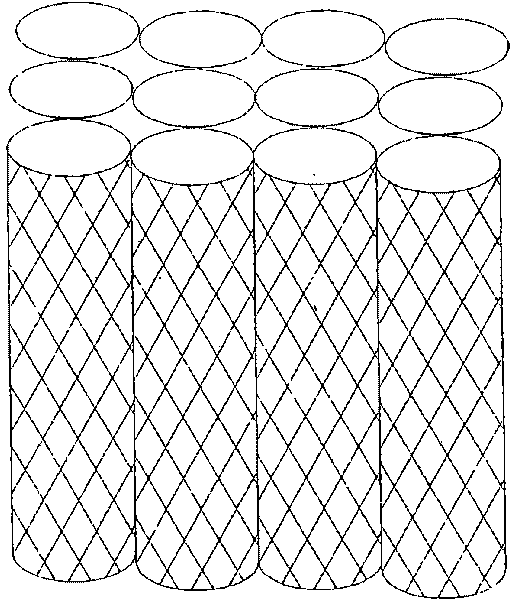

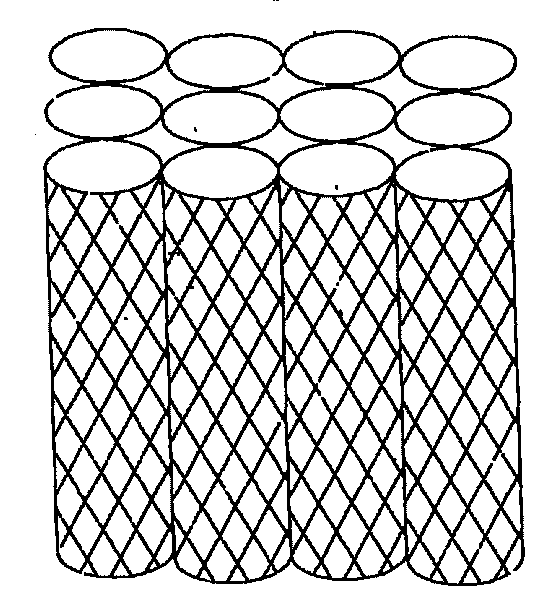

[0013] Example 1: Combining figure 1 , figure 2 , the present invention is a kind of honeycomb network pipe biological carrier, which is made of honeycomb network pipe biological filler, the honeycomb network pipe biological filler is made of modified polyethylene, modified polyvinyl chloride or modified polypropylene material, and carbon black and Polyvinyl alcohol component, honeycomb network tube biological filler is a honeycomb-shaped filler formed under the thermophysical bonding of multiple network tubes, a single network tube is hollow, with a diameter of 8-12cm, and a single network tube is cut into a small network tube with a length of 60-80cm. A plurality of 60-80cm small mesh tubes are bonded together by thermoplastic at the upper part and the bottom to become the biological filler of the honeycomb mesh tube.

[0014] The present invention also has the following technical characteristics:

[0015] The pipe wall holes of the single small net pipe network are diamo...

Embodiment 2

[0017] Example 2: Combining figure 1 , figure 2 , the cellular network pipe biological carrier of the present invention relates to a high-efficiency water treatment biological carrier suitable for biological contact oxidation tanks, which solves the problems of slow film-forming speed, small amount of film-forming and low mass transfer efficiency in the biological carrier area of traditional biological carriers.

[0018] On the basis of the honeycomb tubular filler, the invention develops the honeycomb network tubular biological filler.

[0019] The honeycomb network pipe biological filler is a honeycomb filler formed under the thermophysical bonding of multiple network pipes. The single network tube is hollow with a diameter of 8-12cm, and the single network tube is cut into small network tubes with a length of 60-80cm. A plurality of 60-80cm small mesh tubes are bonded together by thermoplastic at the upper part and the bottom to become the biological filler of the hone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com