Functional peanut small molecule mixed polypeptide, preparation method and application thereof

A functional, small-molecule technology, applied in the field of functional peanut small-molecule mixed polypeptides and its preparation, can solve the problems of low purity of peanut protein polypeptides, long production cycle of preparation methods, and insufficient functionality, and achieve improved flavor and function Effect of high activity, short production cycle, good functional activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 Preparation of the functional peanut small molecule mixed polypeptide of the present invention

[0058] a. water grinding slurry

[0059] Accurately weigh 100 kg of degreased peanut meal, add 1,000 kg of water, and start the colloid mill to refine the pulp until it is in a fine and uniform dispersion state, and pass through a 200-300 mesh sieve for later use;

[0060] b. Acid-base treatment

[0061] Under stirring, add an aqueous acid solution to the water slurry prepared in step a, and adjust the pH between 4-5.5 and stabilize it, then let it settle for 20-30 minutes, and remove the supernatant; add water to the precipitated crude protein slurry , control the ratio of parts by weight of crude protein to water to be 1:5; start stirring and add an aqueous solution of alkali to adjust the pH value at 8-8.5 and stabilize it, then pump the feed liquid into the enzymolysis reaction kettle to prepare for enzymolysis;

[0062] c. Stage enzymatic hydrolysis, cleavage,...

Embodiment 2-6

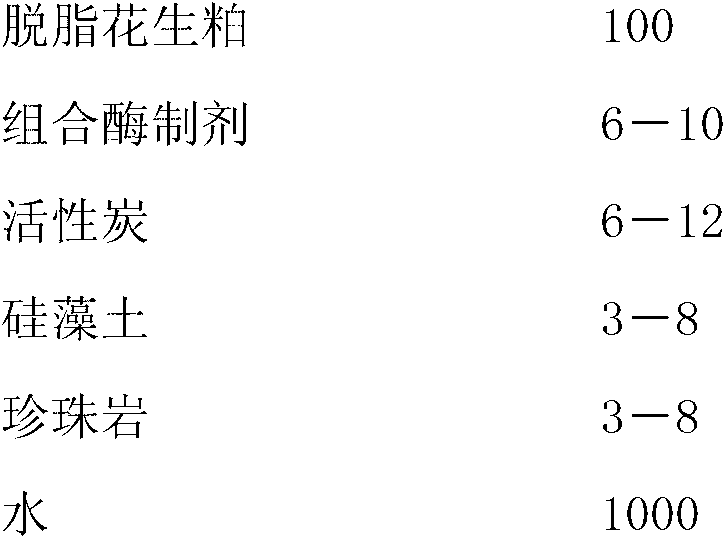

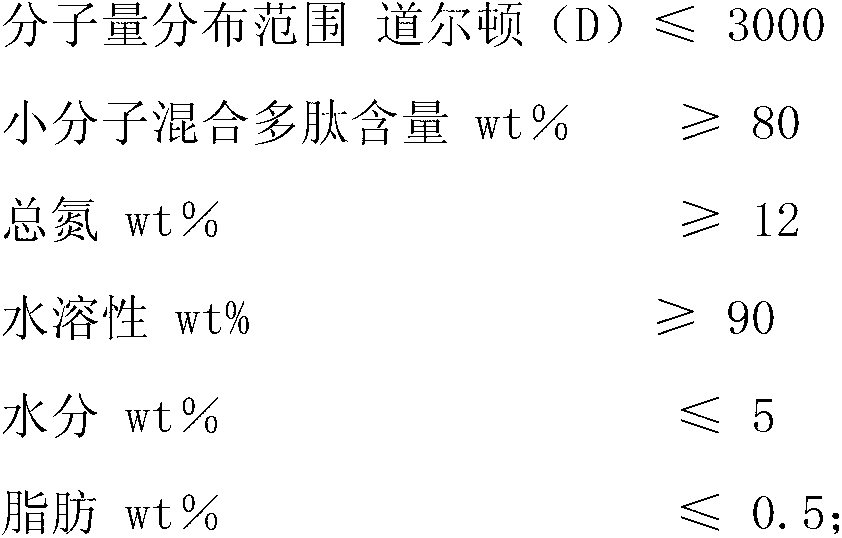

[0085] According to the method and steps of Example 1, according to the ingredients in Table 1, the functional peanut small molecule mixed polypeptide product of the present invention is prepared

[0086] Table 1

[0087] Raw materials and product indicators

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com