Magnesium alloy refining unit

A smelting equipment and magnesium alloy technology, applied in the field of purifying smelting equipment for magnesium alloys, can solve the problems of large metal oxidation and burning loss, reduced quality and performance, and more inclusions in magnesium alloys, and achieve small metal oxidation and burning loss, The effect of improved quality and performance, ease of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

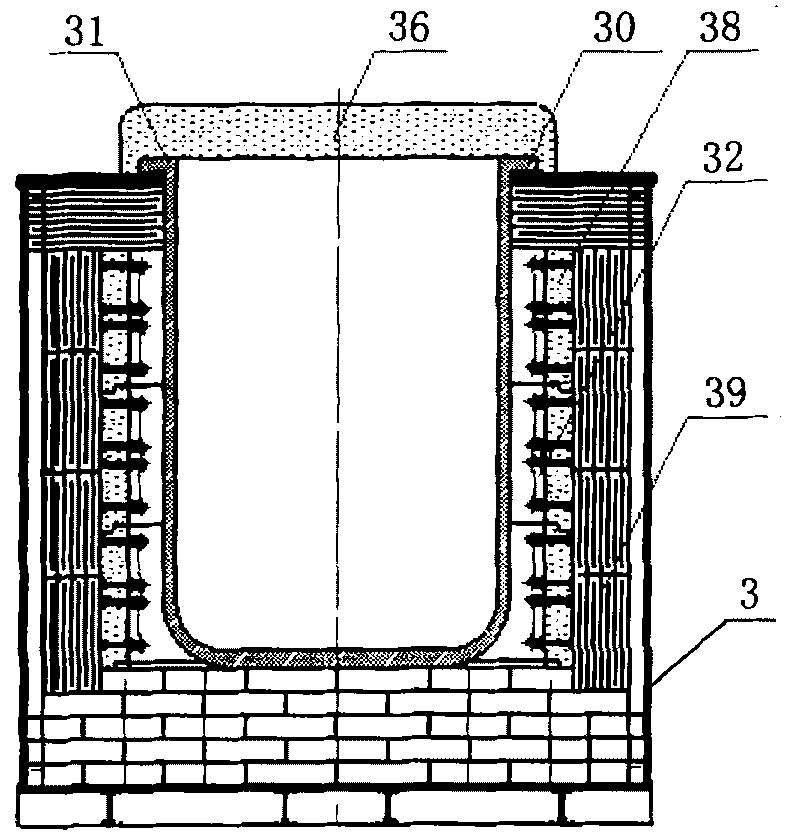

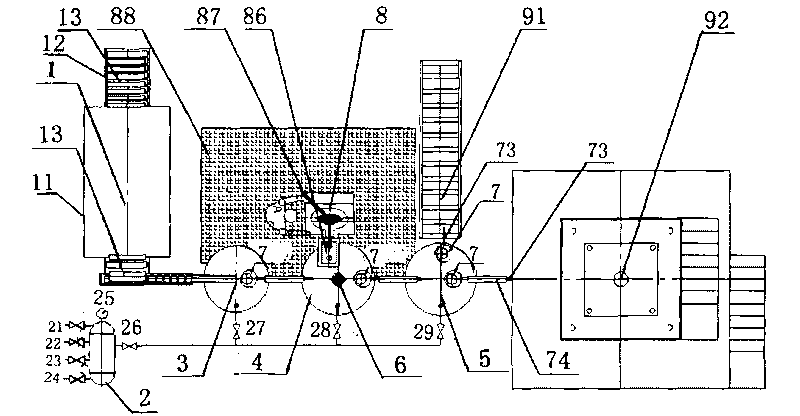

[0054] Embodiment 1: 1000 kilograms of AZ91D magnesium alloy smelting method.

[0055] 1. Melting preparation

[0056] Connect the power supply of preheating furnace 1, melting furnace 3, alloying furnace 4 and standing holding furnace 5, and heat up. The preheating furnace 1 is heated up to 420-460°C, the melting furnace 3, the alloying furnace 4 and the static holding furnace 5 are respectively heated up to 600-620°C, and the protective gas (0.2-0.5vt% SF 6 +N 2 That is, the protective gas contains 0.2 to 0.5 volume percent of SF 6 , and the rest are N 2 ).

[0057] 2. Preheating of pure magnesium ingot

[0058] A preheating furnace 1 is used to preheat the pure magnesium ingot with a clean surface to 380-420°C.

[0059] 3. Pure magnesium ingot melting

[0060]First add 100-120 kg of pure magnesium ingots with a clean surface to completely melt them under the protection of the aforementioned mixed gas, and then add the pure magnesium ingots preheated to the set temper...

Embodiment 2

[0067] Embodiment 2: 1000 kilograms of AZ80 magnesium alloy smelting method.

[0068] 1. Melting preparation

[0069] Connect the power supply of preheating furnace 1, melting furnace 3, alloying furnace 4 and standing holding furnace 5, and heat up. The temperature of the preheating furnace 1 is raised to 420-460°C, the temperature of the melting furnace 3, the alloying furnace 4 and the static holding furnace 5 is raised to 600-620°C, and a protective gas (0.2-0.5vt% SF 6 +N 2 That is, the protective gas contains 0.2 to 0.5 volume percent of SF 6 , and the rest are N 2 ).

[0070] 2. Preheating of pure magnesium ingot

[0071] A preheating furnace 1 is used to preheat the pure magnesium ingot with a clean surface to 380-420°C.

[0072] 3. Pure magnesium ingot melting

[0073] First add 100-120 kg of pure magnesium ingots with a clean surface to completely melt them under the protection of the aforementioned mixed gas, and then add the pure magnesium ingots preheated t...

Embodiment 3

[0080] Embodiment 3: 1000 kilograms of AS41B magnesium alloy smelting method.

[0081] 1. Melting preparation

[0082] Connect the power supply of preheating furnace 1, melting furnace 3, alloying furnace 4 and standing holding furnace 5, and heat up. The temperature of the preheating furnace 1 is raised to 420-460°C, the temperature of the melting furnace 3, the alloying furnace 4 and the static holding furnace 5 is raised to 600-620°C, and a protective gas (0.2-0.5vt% SF 6 +N 2 That is, the protective gas contains 0.2 to 0.5 volume percent of SF 6 , and the rest are N 2 )

[0083] 2. Preheating of pure magnesium ingot

[0084] A preheating furnace 1 is used to preheat the pure magnesium ingot with a clean surface to 380-420°C.

[0085] 3. Pure magnesium ingot melting

[0086] First add 100-120 kg of pure magnesium ingots with a clean surface to completely melt them under the protection of the aforementioned mixed gas, and then add the pure magnesium ingots preheated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com