Multi-adaptive cutter head for shield machine

A shield machine, adaptable technology, applied in mining equipment, earthwork drilling, tunnels and other directions, can solve the problems of shield machine cutter head difficult to adapt, dangerous, difficult to replace the hob, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

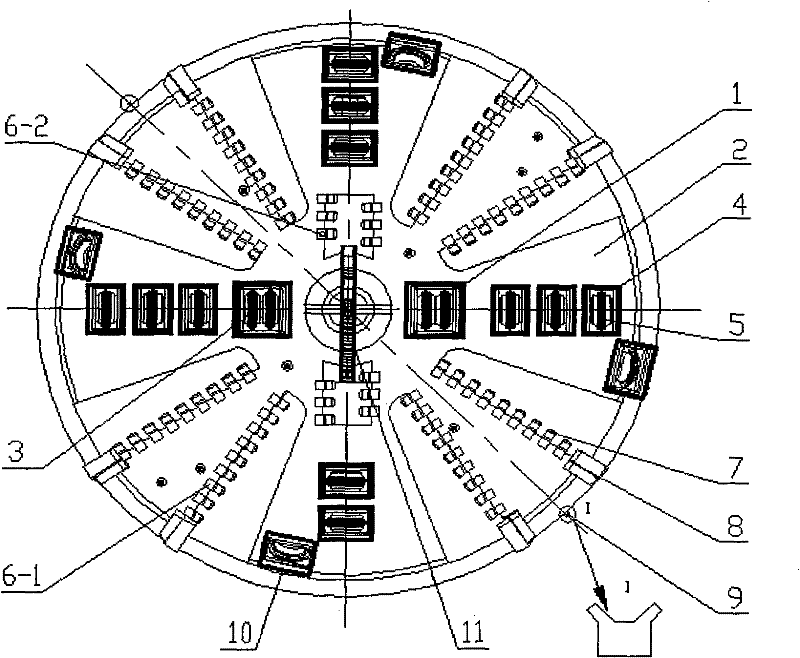

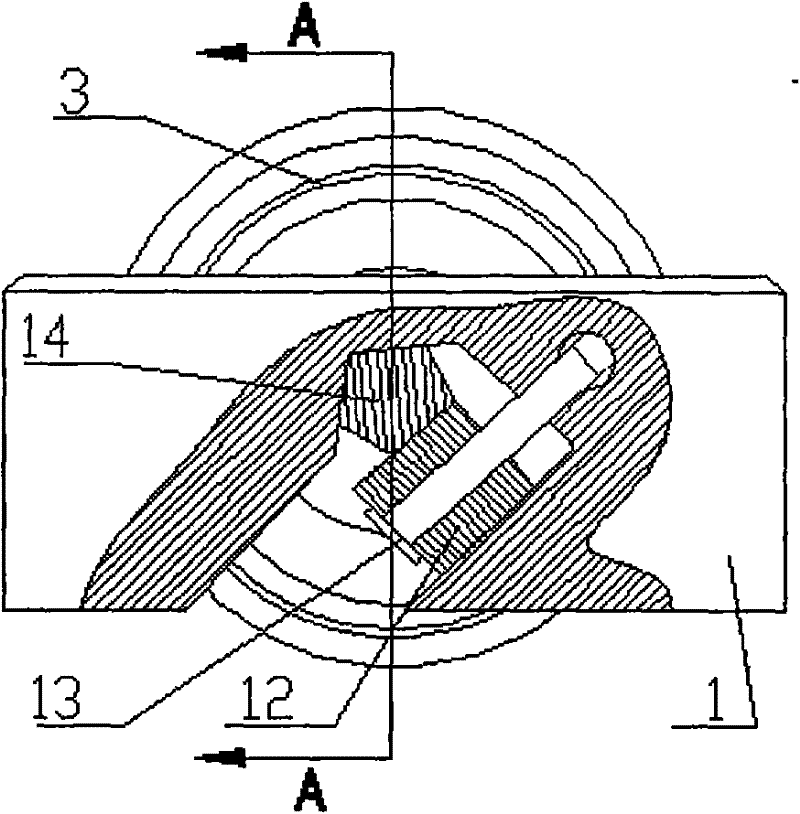

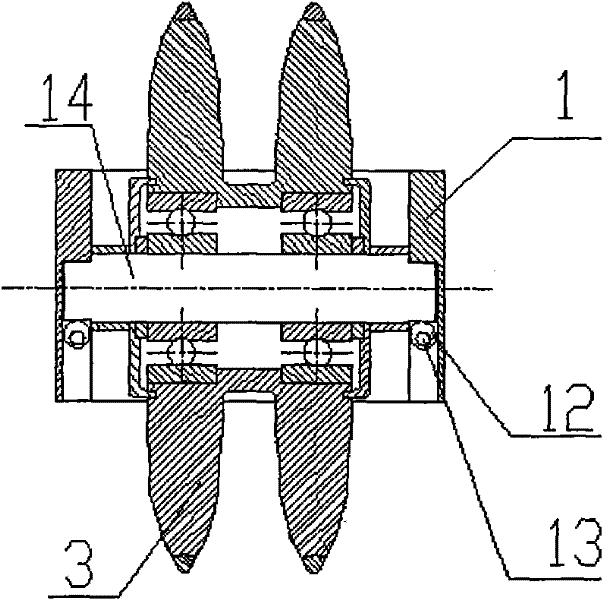

[0014] The principle and structure of the present invention will be further described below through specific examples. The adaptable cutter head of the earth pressure balance shield machine is composed of three parts: the cutter head body, the interchangeable knife seat and the cutter (such as figure 1 ). Its specific structure is: two central double-edged hob seats 1 are arranged symmetrically in a straight line from the inside to the outside with a distance less than or equal to 1 / 3 of the radius of the cutterhead body 2, and the central double-edged hob seat 1 is embedded with a double-edged hob 3 The 11 interchangeable knife seats 4 are distributed in a spiral line along the circumference at a distance of 1 / 3 to 4 / 5 of the radius of the cutter head body 2 from the inside to the outside, and all the interchangeable knife seats 4 are divided into horizontal and vertical rows. The center of the cutter head body 2 is a dot arranged as a cross line, and the interchangeable cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com