Engine simulator for dynamic simulation test in high-speed wind tunnel

A dynamic simulation, high-speed wind tunnel technology, applied in the field of experimental simulators, can solve problems such as difficulty in measuring design-related parameters, and achieve the effects of compact structure, accurate experimental data, and scientific and rigorous design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

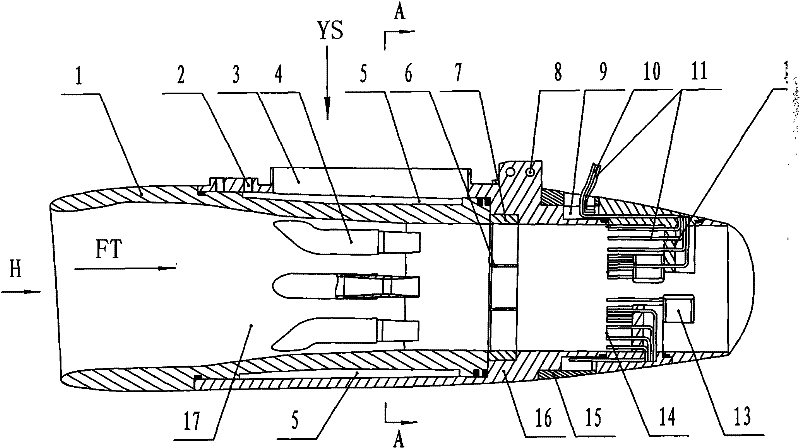

[0027] See attached Figure 1~4 As shown, the engine simulator of the present invention is fixedly connected on the hanger 20 of the model 19 with screws, and what links to each other with the hanger 20 is the front fixed point 2 and the rear fixed point 8; the wind tunnel airflow FT enters from the front end of the present invention.

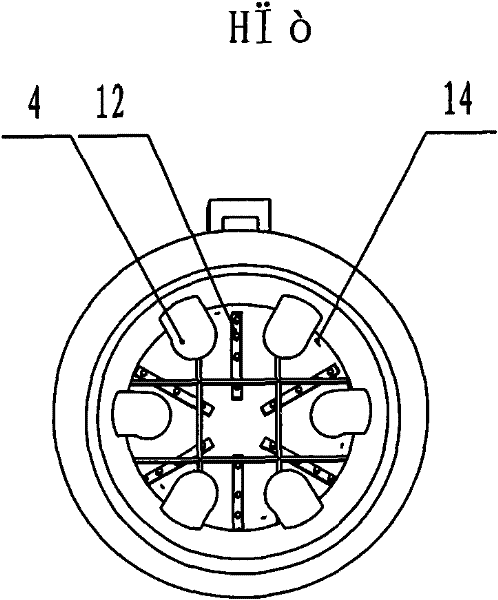

[0028] An engine simulator used for high-speed wind tunnel dynamic simulation experiments, including (simulating a complete engine) an outer casing 1 and an ejection device, a rectifying device and a pressure measuring device installed in the outer casing 1; the outer casing 1 is a simulated The complete engine body, the above-mentioned injection device, comprises air inlet 3, gas collecting ring 5 and a plurality of nozzle pipes 4; The gas collecting ring 5 is connected, the gas collecting ring 5 is an annular cavity and is located on the inner wall of the outer casing 1, and a plurality of nozzles 4 are evenly and symmetrically arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com