Hydrogen gas sensor based on thermal conduction principle

A sensor and sensor housing technology, applied in the field of hydrogen sensors, can solve the problems of limiting the advantages and promotion of thermal conductivity sensors, baseline drift, etc., and achieve the effects of compact structure, reduced impact, and slow thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

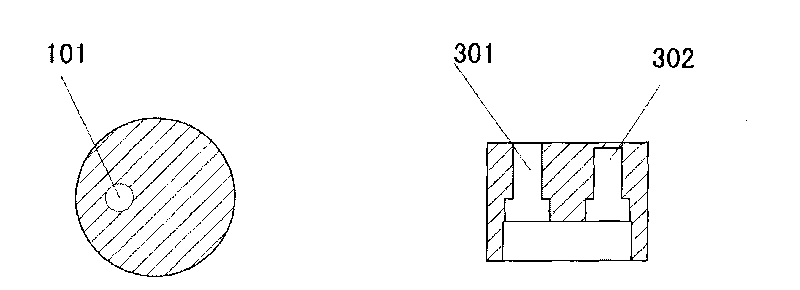

[0033] 1 heat-sensitive metal wire is wound on the glass 28 to make measurement thermistor 101 and reference thermistor 102;

[0034] 2 The measuring thermistor 101, the reference thermistor 102 and the bridge resistance 201 form a Wheatstone bridge, the measuring thermistor 101 is located on the upper side of the measuring pool PCB board 401, and the reference thermistor 102 is located in the reference pool On the upper side of the PCB board 402, the bridge resistors 201 are located on the lower side of the respective corresponding PCB boards, maintaining the symmetry between the resistors;

[0035] 3 A cylindrical aluminum block with a diameter of 4 cm and a height of 3 cm, on which a circular through hole with a diameter of 7.2 mm is processed, which is the measurement pool 301, and the other 7.2 mm circular hole is not connected, which is the reference pool 302;

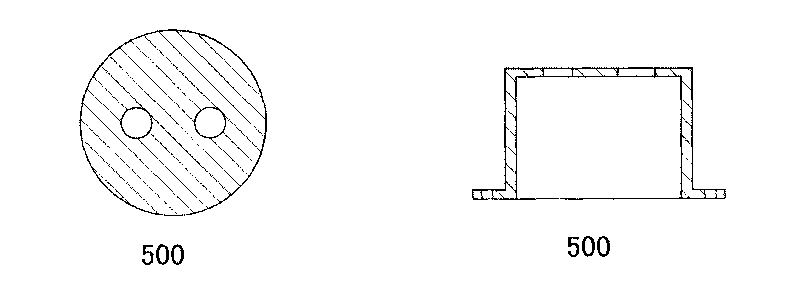

[0036] 4 Install two PCB boards into their respective pools, and seal them with baffles 502;

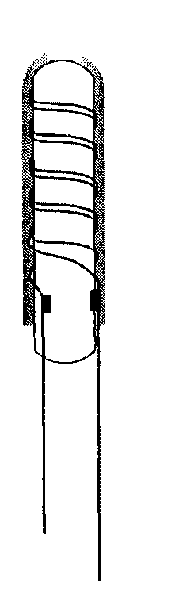

[0037] 5 The t...

Embodiment 2

[0040] Four identical thermistors are used to form a Wheatstone bridge, one of which is a measuring resistor, one is a reference resistor, and the other two are used as bridge resistors. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Membrane pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com