Suspending manufacture process of light emitting diode (LED) fluorescent powder

A manufacturing process and phosphor technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven luminous spot, small size of low-power LEDs, and high technical difficulty, achieve uniform coverage, improve utilization, and resist attenuation. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

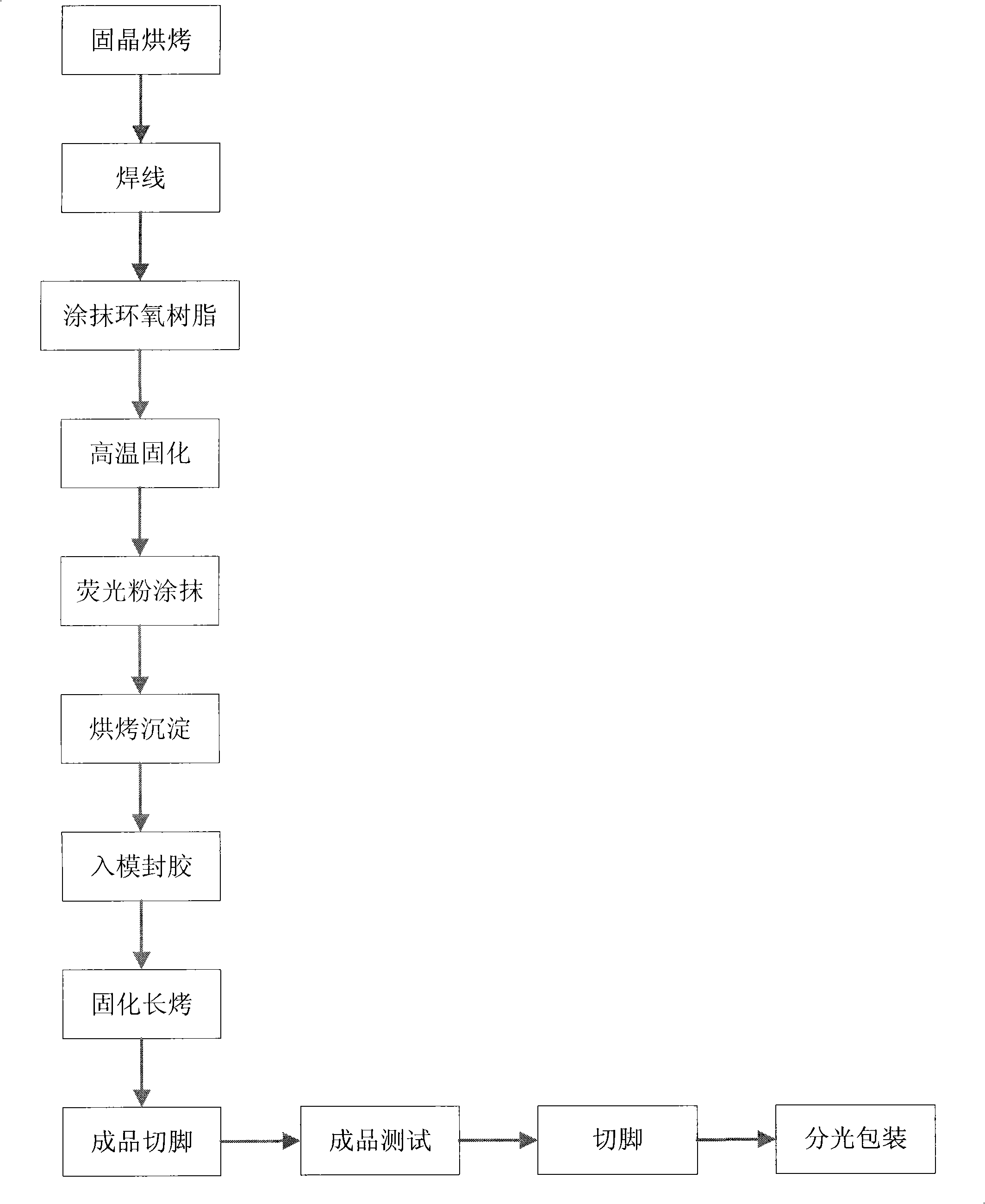

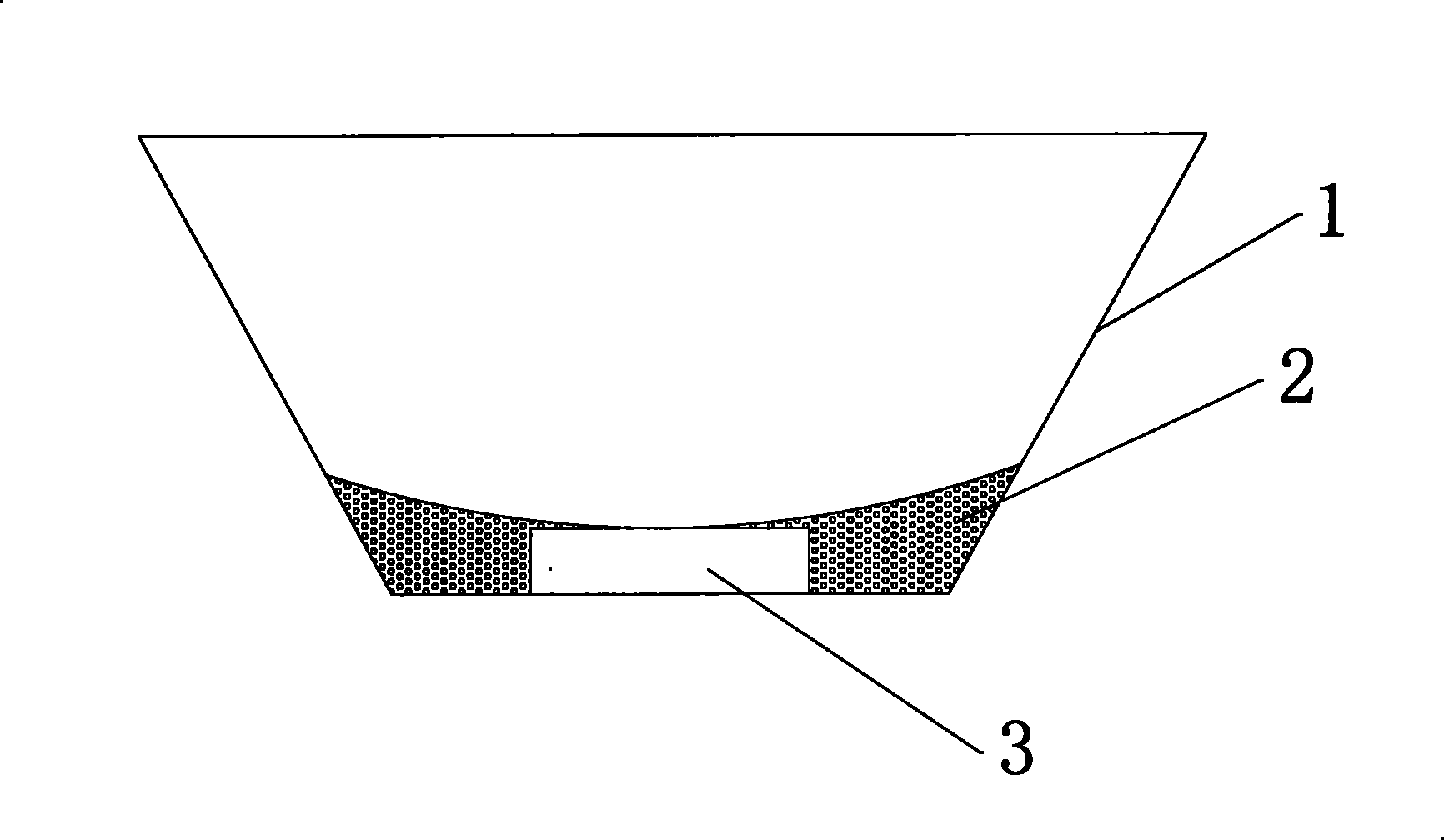

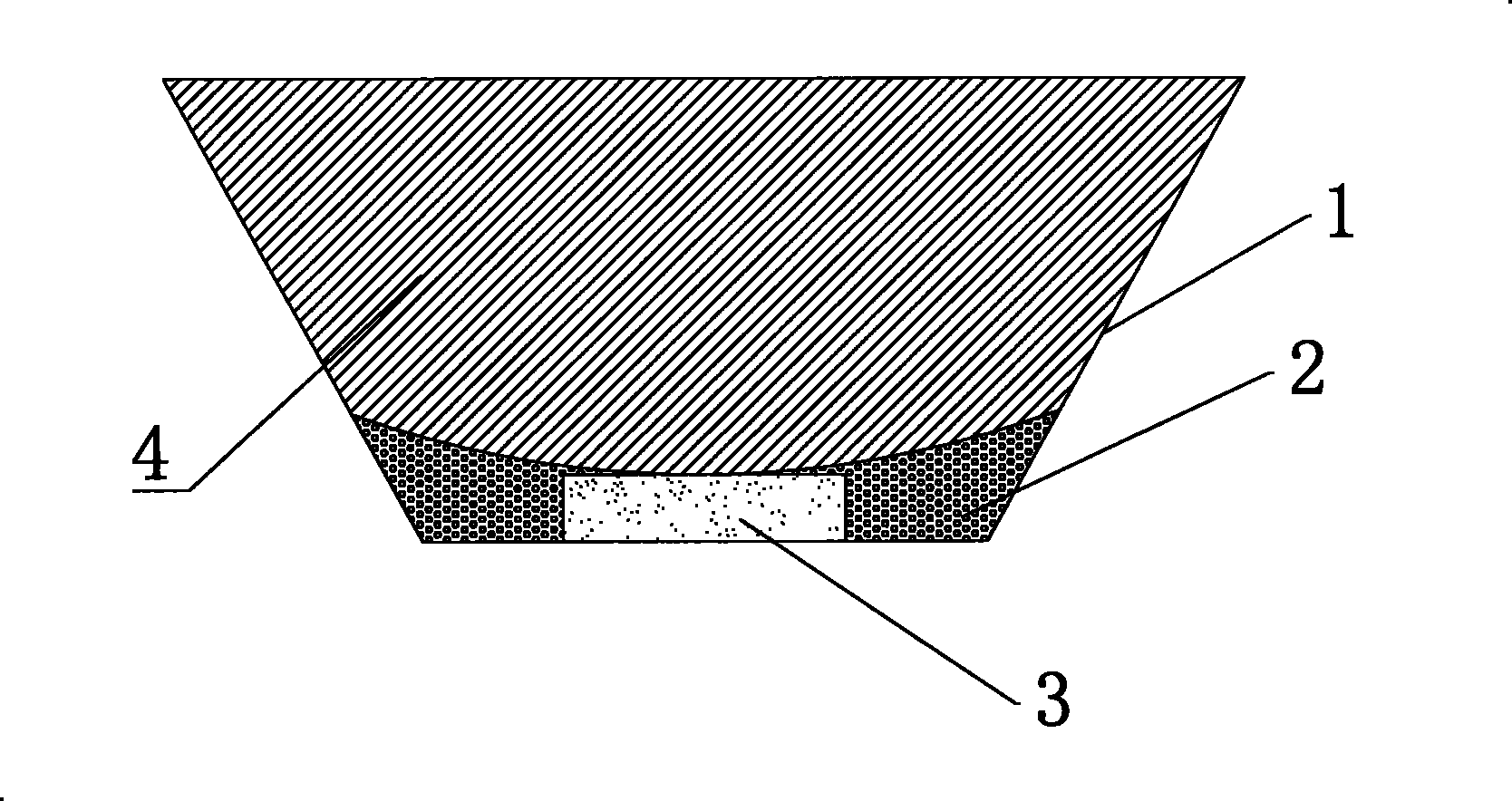

[0043] like figure 1 Shown, the present invention relates to a kind of LED phosphor suspension manufacturing process, it comprises the following steps

[0044] a), solid crystal baking

[0045] Put insulating glue in the middle of the bracket of the lamp cup, bond the light-emitting chip to the bracket, and then put it in a hot air circulation oven and bake at 130-150 degrees Celsius for 60 minutes to cure the insulating glue;

[0046] The peeling force of the wafer and the support should be greater than 70 grams;

[0047] b), welding wire

[0048] Through the special LED wire bonding equipment, the gold wire is soldered to the chip pad and the bracket to form a power circuit;

[0049] The tearing force of the welded gold wire should be greater than 5 grams;

[0050] c), apply epoxy resin

[0051] Put an appropriate amount of epoxy resin on the chip in the lamp cup, it is best to just cover the chip. The epoxy resin is a transparent two-component epoxy resin, which is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com