Method for controlling the precipitation of alumina

An alumina and precipitation technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, aluminate/alumina/aluminum hydroxide purification, etc., can solve the problems of poor quality, excessive purchase cost of lime, etc. Achieve the effect of increasing A/TC and improving precipitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0168] Best Mode for Carrying Out the Invention

[0169] The present invention focuses on the control of alumina precipitation in the Bayer process by the exchange of sodium ions in the Bayer process solution with ions on a solid support. By careful control of the exchange conditions, the precipitation of alumina from aluminate solutions can be controlled.

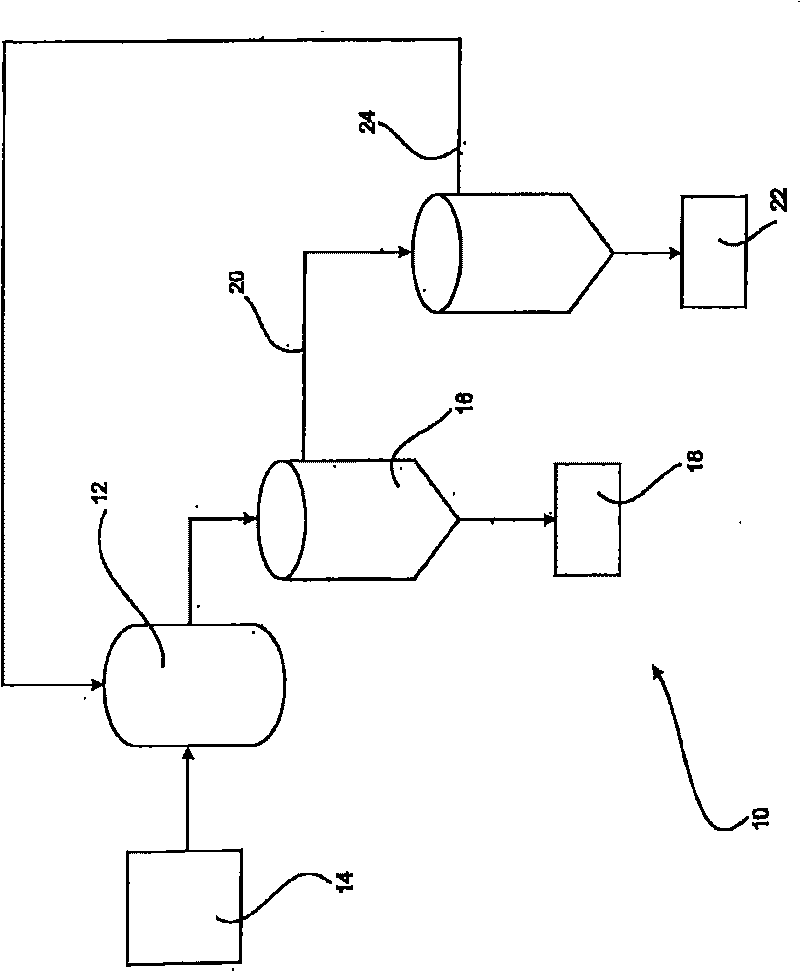

[0170] Figure 1a A schematic flow diagram showing a Bayer process for a refinery using a single digestion process, the Bayer process comprising the following steps:

[0171] Digest 12 bauxite 14 in a caustic solution;

[0172] liquid-solid separation 16 of the mixture into a residue 18 and a liquid 20;

[0173] Precipitating alumina 22 from liquid 20;

[0174] Separation of alumina 22 and liquid 24; and

[0175] The liquid 24 is recycled to the digestion 12 .

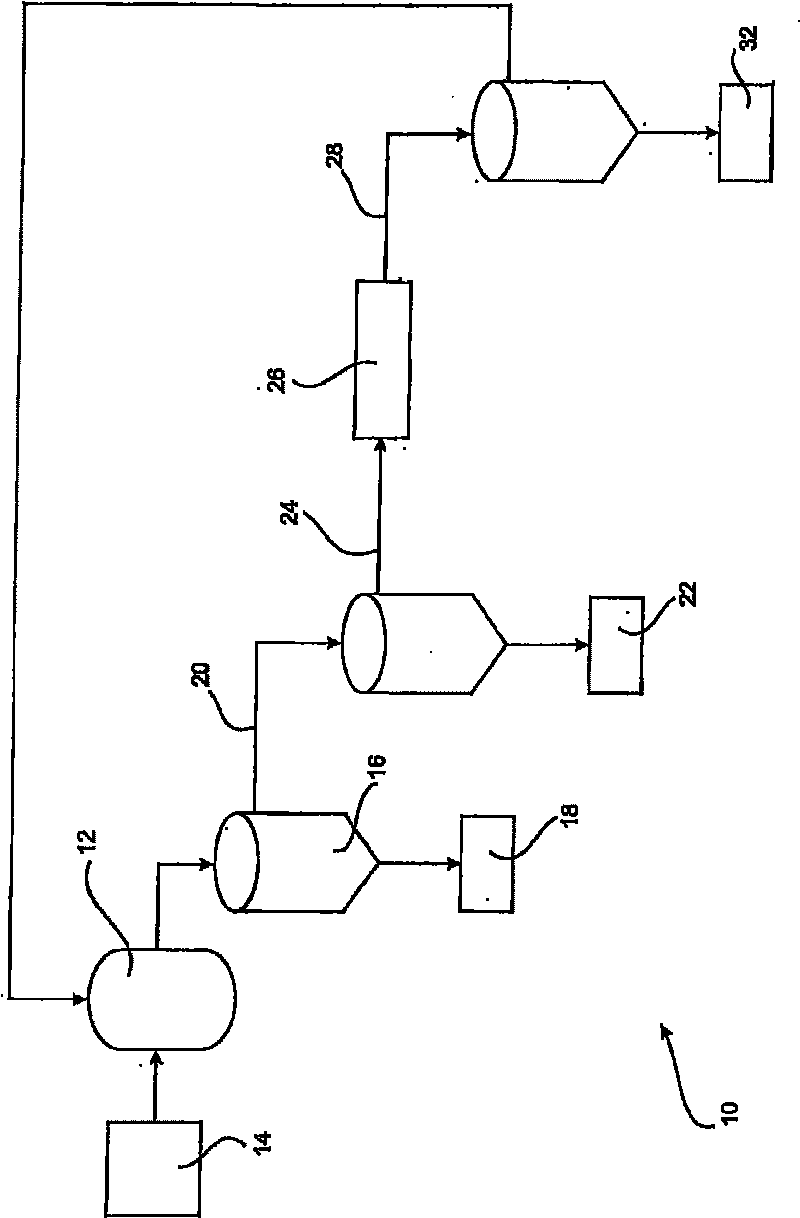

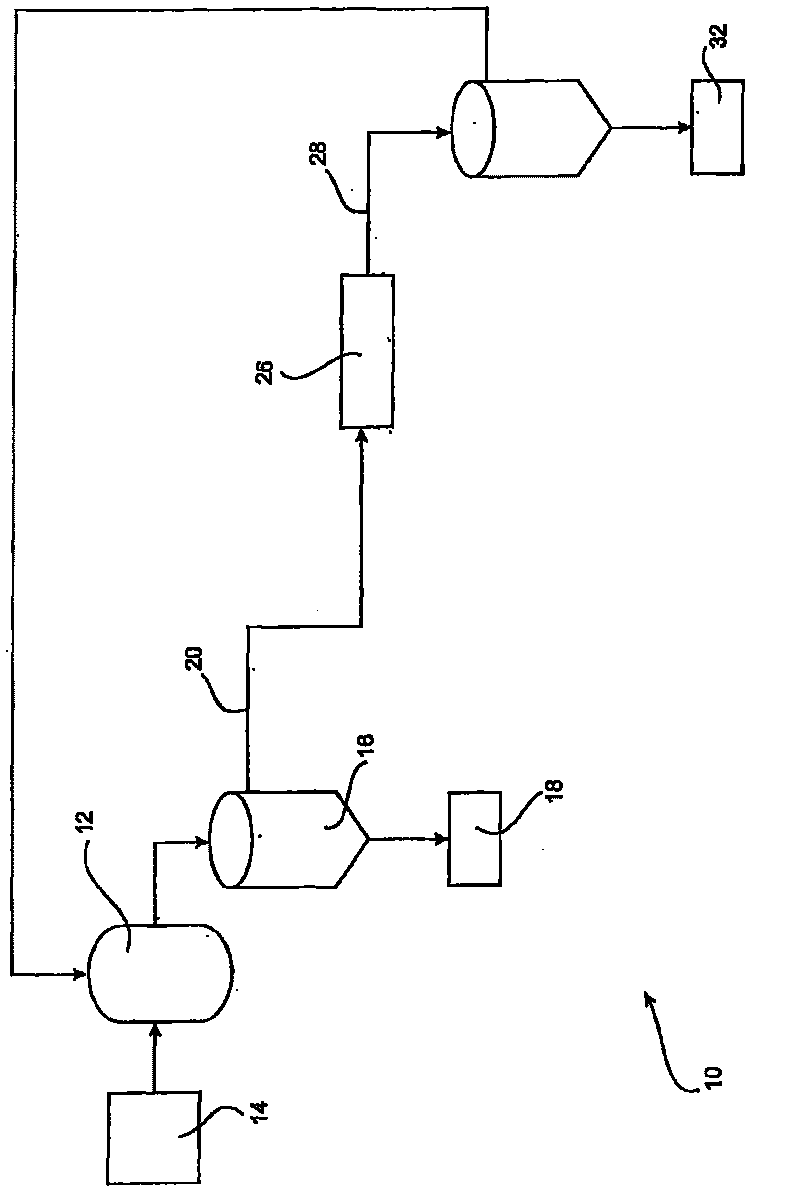

[0176] According to the first embodiment of the present invention and in Figure 1b As seen most clearly in , liquid 24 contacts ion exchange resin in ion ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com