Stream movable casting machine

A motion type, pouring machine technology, used in equipment that feeds molten metal into molds, metal processing equipment, casting equipment, etc. problem, to achieve the effect of small distance, reduction of secondary oxidation, and reduction of splashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

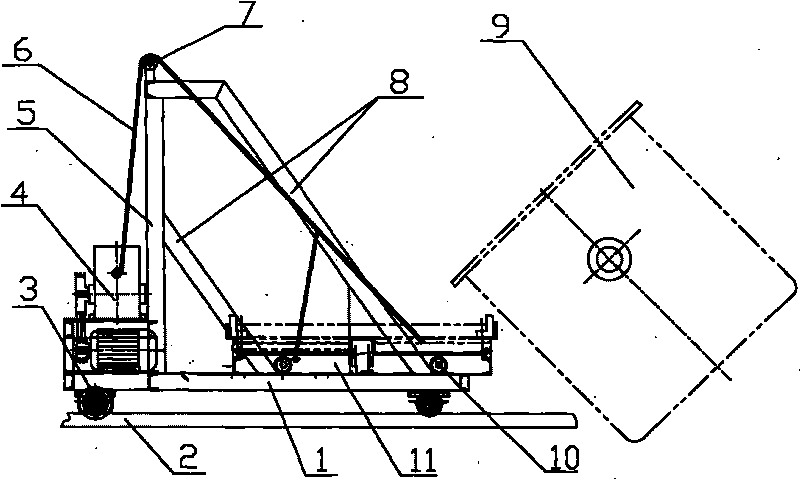

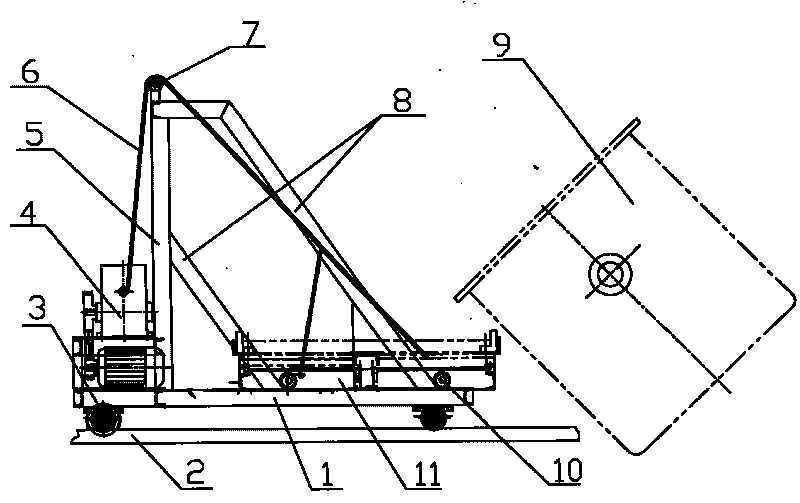

[0008] A flow-moving pouring machine, comprising a track 2, traveling wheels 3, and a running trolley 1, the running trolley 1 is set on the track 2 through the traveling wheels 3, a bracket 5 and an inclined rail 8 are installed on the running trolley 1, and a mold trolley 11 The roller 10 uses the beam body of the running trolley 1 and the inclined rail 8 as the track, the hoist 4 is fixed on the running trolley 1, the steel wire rope 6 is set on the guide rope wheel assembly 7 on the bracket 5, and one end is connected with the hoist 4, The other end is connected with the mold trolley 11, and the product mold is placed on the mold trolley 11. The track 2 and the running trolley 1 are installed in front of the tilting furnace body 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com