Monitoring control system of paper-making machine drying part energy system and working method thereof

A technology for monitoring and controlling the drying section, which is applied in the direction of paper machines, dryers, and papermaking, and can solve the problem of incomplete measurement data, inability to monitor and optimize the efficiency of energy utilization and recovery levels in the drying section, and ineffective integration and analysis And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

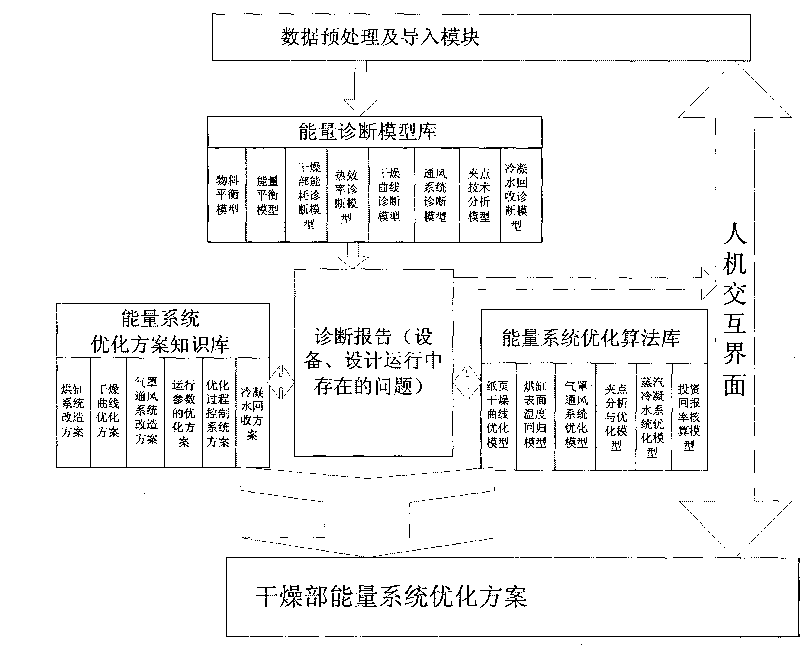

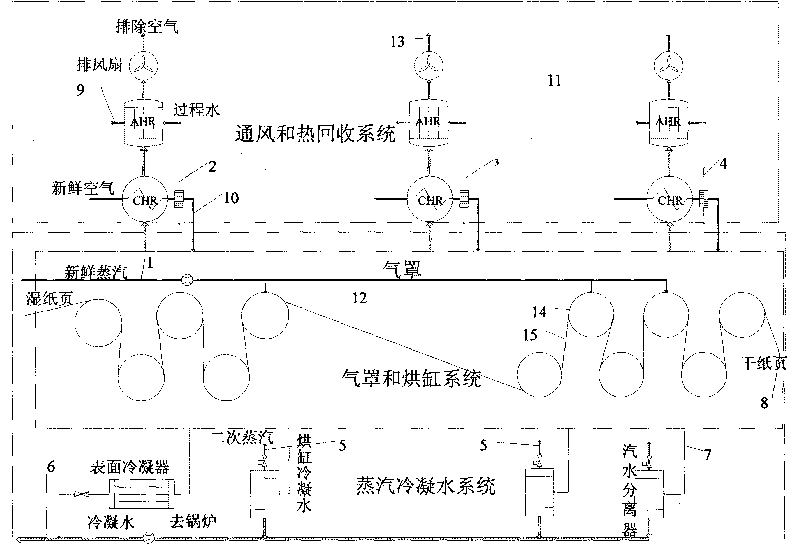

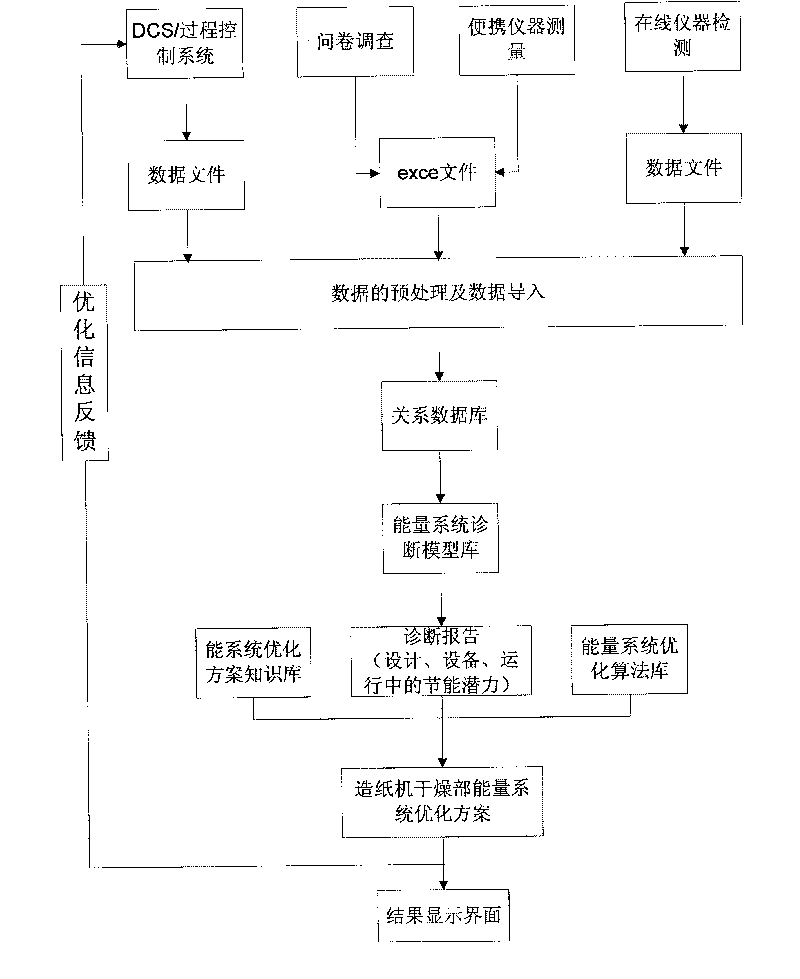

[0059] Taking a newsprint machine with a production capacity of 500 tons per day as an example to illustrate the monitoring and control of the present invention on the drying section of a paper machine. The structural representation of the system of the present invention is as figure 1 As shown, it includes: a data preprocessing and import module for unifying the format and unit of the collected logistics data of the drying section of a paper machine and storing it in a relational database module; a relational database module for storing and converting data; An energy system diagnostic model database for diagnostic analysis of the logistics data stored in the relational database; an energy system optimization scheme knowledge base and an optimization algorithm for optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com