Improved construction technology of CFG (cement fIying-ash gravel) pile

A kind of construction technology and technical technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of construction disturbance, soil strength reduction, pile body mixed with soil, etc., and achieve high bearing capacity, large friction force, and tight combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

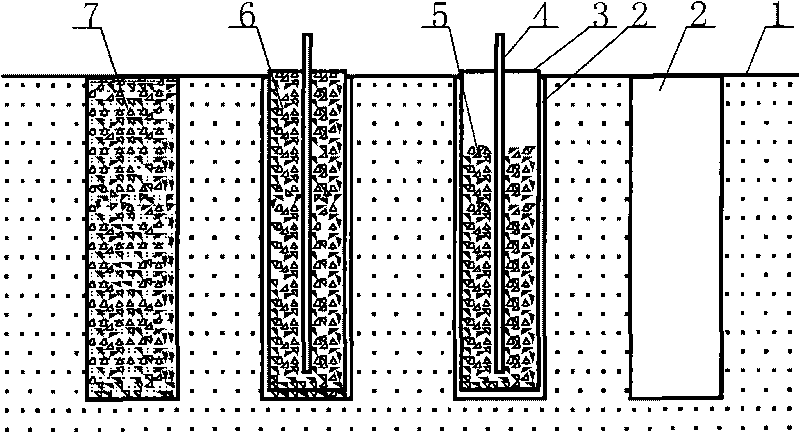

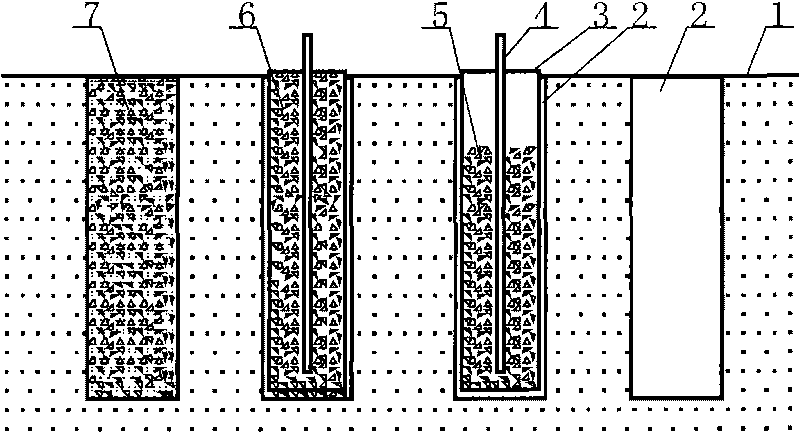

Image

Examples

Embodiment

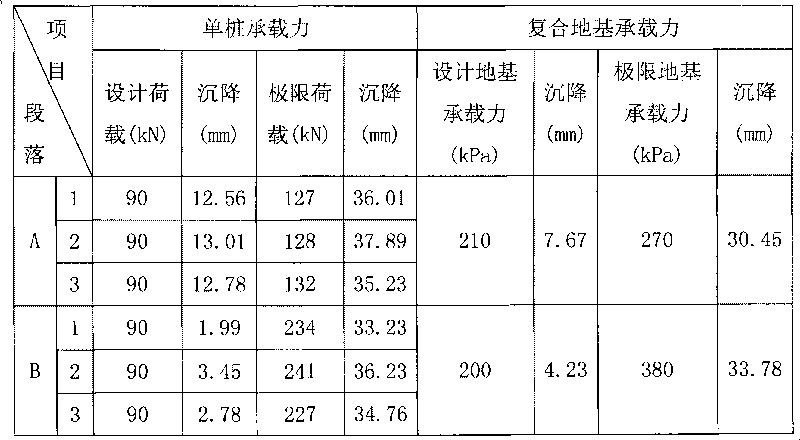

[0025] In order to verify the feasibility of the construction method, the CFG pile soft foundation treatment section of Guangwu Expressway was verified. Two sections were compared. Section A adopts the unimproved CFG pile construction technology. The test pile length is 8.5m, and the total is 1202. Root; Section B adopts improved CFG pile treatment technology. The test pile length is 8.5m. There are 1234 piles in total. The diameter of the CFG piles is 50cm, and the spacing of the piles is 1.5m. The plum blossom-shaped full hall layout is adopted. According to the specification requirements, after the completion of the construction and reaching the age, in accordance with the "Technical Specification for Highway Subgrade Construction" (JTG F10-2006), section A shall be tested for the bearing capacity of 3 single piles and 1 composite foundation, and 60 core-pulling tests. In Section B, the bearing capacity of 3 single piles and the bearing capacity of 1 composite foundation, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com