Recycled concrete coarse aggregate modified processing method

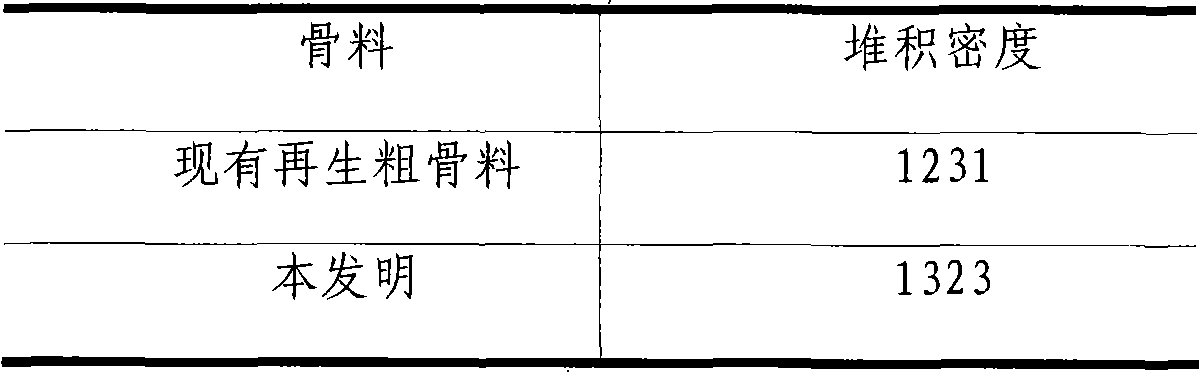

A technology of recycled concrete and recycled coarse aggregates, applied in the field of building materials, can solve the problems of low bulk density affecting aggregate gradation, etc., and achieve the effects of improving aggregate grading, increasing compressive strength and sufficient cement hydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Raw material backup:

[0013] Regenerated coarse aggregate comes from demolition waste concrete, after crushing, cleaning and grading, the selected particle size is 5-10mm. The cement is Gongyuan brand P.S32.5 slag portland cement.

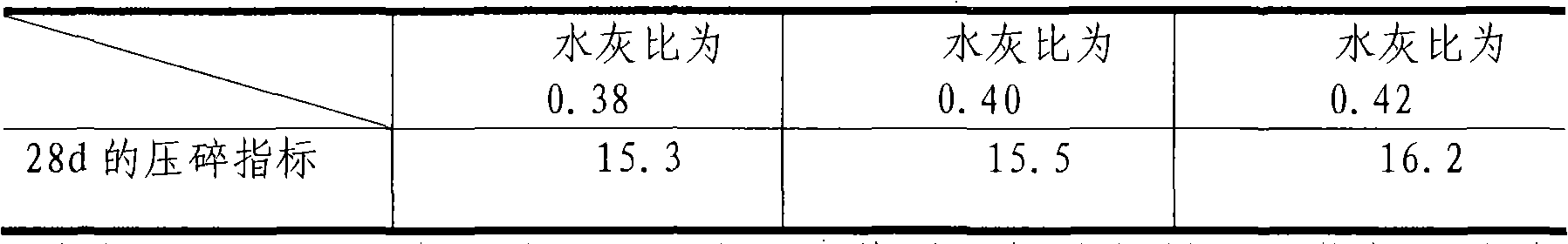

[0014] Modification treatment method:

[0015] According to the three situations of water-cement ratio of 0.38, 0.40, 0.42, adjust the cement slurry, add 0.2% polycarboxylate high-efficiency water reducer relative to the cement quality, first mix the water reducer and water thoroughly, and then pour it into the prepared cement , fully mix the two, and then put the spare recycled coarse aggregate into the mixer, mix it with the cement slurry added with the water reducing agent under the condition of stirring, make it fully contact with the cement slurry, and then soak for 30-35 Minutes, the modified recycled coarse aggregate is obtained.

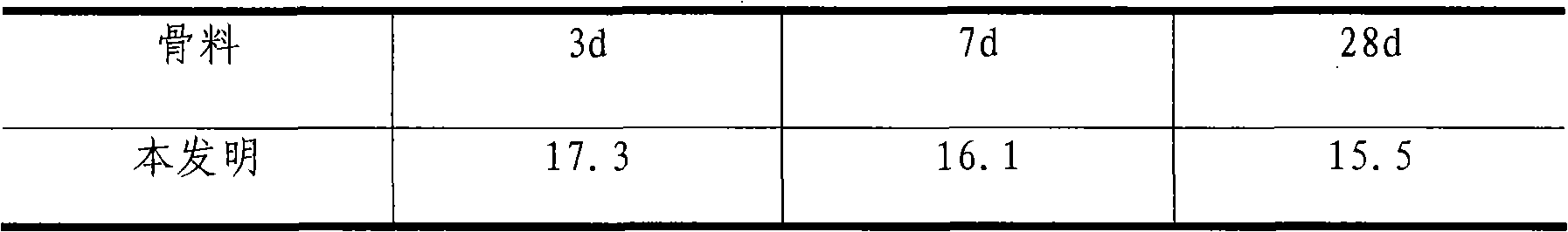

[0016] The regenerated coarse aggregate of the above-mentioned modified treatment is filtered out wi...

Embodiment 2

[0038] The recycled coarse aggregate comes from demolition waste concrete whose model is above C30. After crushing, cleaning and grading, the selected particle size is 10-20mm.

[0039] Cement is 325 # Model above 425 # 、525 # .

[0040] Modification treatment method:

[0041] Adjust the above-mentioned cement so that the water-cement ratio is 0.36, and then add 0.6% of its weight molasses water-reducer to the cement with the adjusted water-cement ratio. Fully soak the aggregate, mix the two fully, then put the spare recycled coarse aggregate into the mixer, mix it with the cement added with the water reducer under the condition of stirring, make it fully contact with the cement slurry, and then soak After 35-40 minutes, the modified recycled coarse aggregate is obtained.

Embodiment 3

[0043] The recycled coarse aggregate comes from demolition waste concrete whose model is above C60. After crushing, cleaning and grading, the selected particle size is 10-20mm.

[0044] Cement is 425 # Model above 525 # .

[0045] Modification treatment method:

[0046] Adjust the above cement to have a water-cement ratio of 0.46, then add 0.4% lignin water reducer by weight to the cement with adjusted water-cement ratio, fully mix the two, and then put the spare recycled coarse aggregate into Mixer, under the condition of stirring, mix with cement added with water reducing agent, make it fully contact with cement slurry, and then soak for 20-30 minutes to obtain modified recycled coarse aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com