S-shaped channel type anaerobic fermentation device

An anaerobic fermentation, channel-type technology, applied in biochemical instruments, waste fuels, biochemical equipment and methods, etc., can solve problems such as difficult to achieve "continuous flow" reaction, lack of fluidity, and maintenance of anaerobic bacteria , to achieve the effect of simple and easy large discharge, promotion of fluidity, and convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

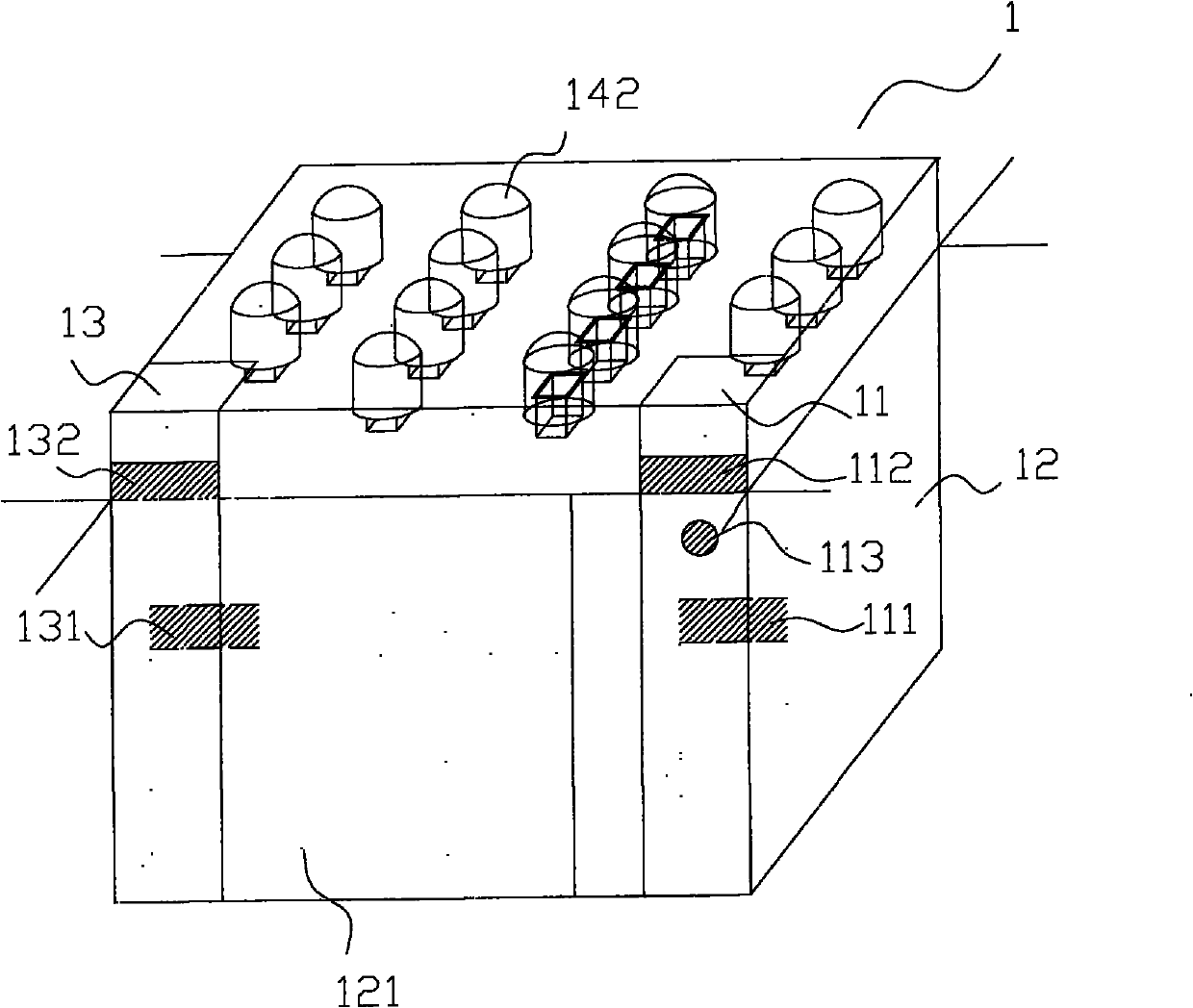

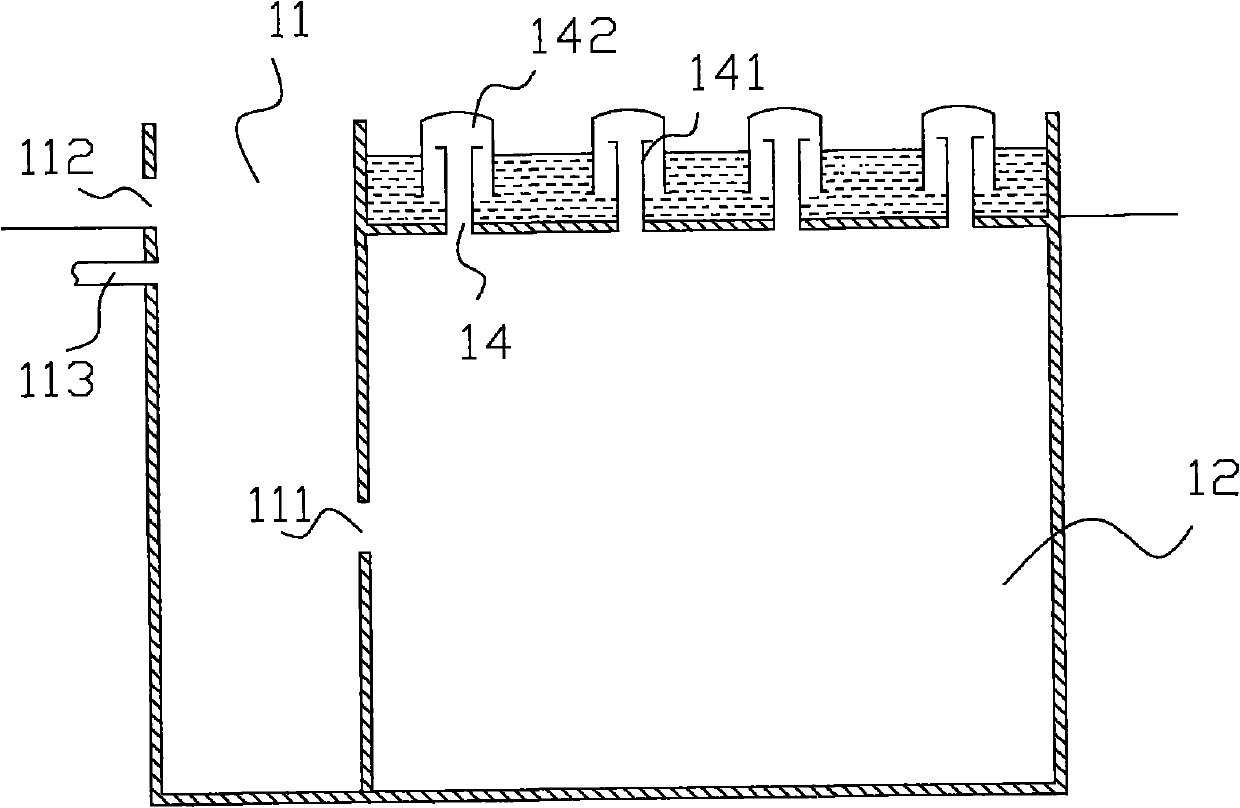

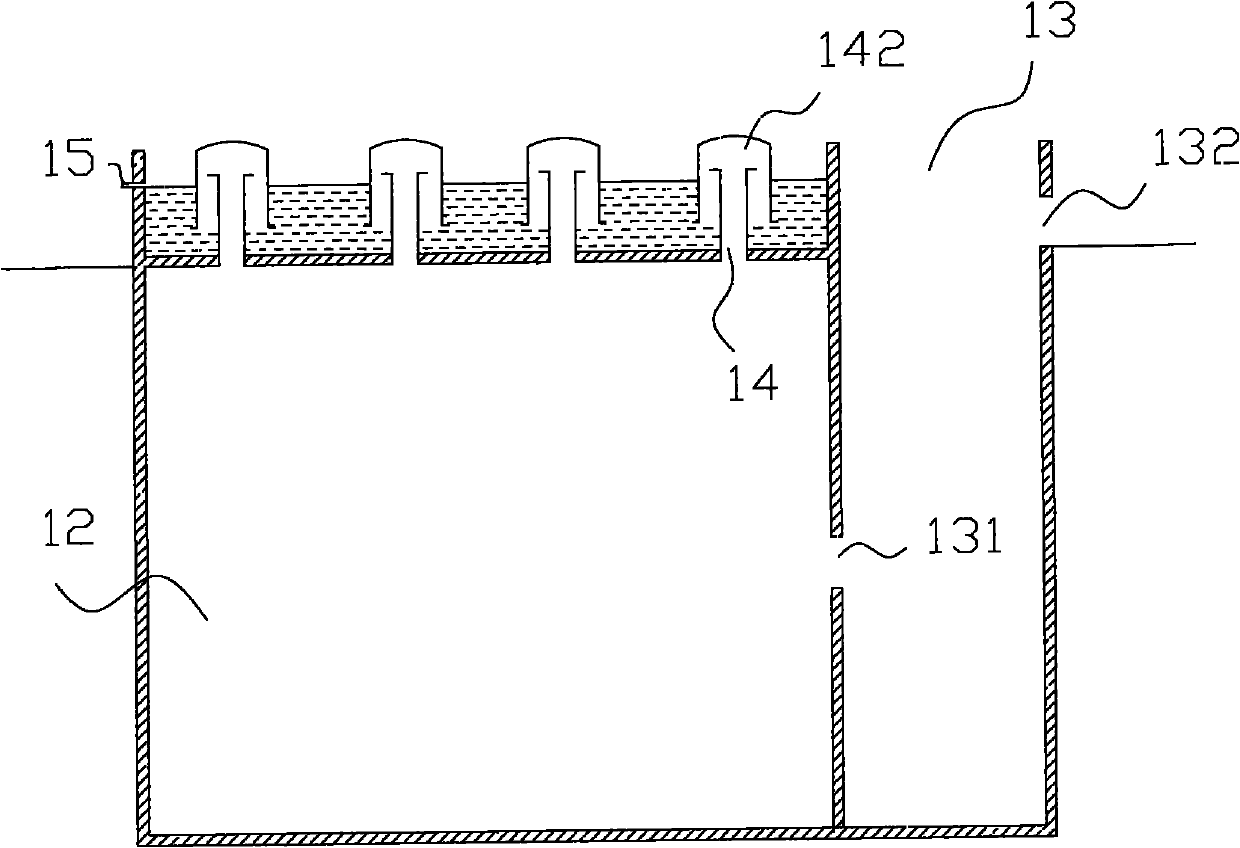

[0025] Such as figure 1 , figure 2 with image 3 Shown, a kind of S type channel type anaerobic fermentation device 1 is made of feed pool 11, anaerobic generation pool 12 and discharge pool 13, and feed pool 11, anaerobic generation pool 12 and discharge pool 13 are all made of It is made of bricks or poured with concrete, wherein the feed pool 11 and the discharge pool 13 are located on both sides of one side of the anaerobic generation pool 12, and the height of the upper end of the feed pool 11 and the discharge pool 13 is higher than that of the anaerobic generation pool. pool 12, the top of the anaerobic generation pool 12 is sealed, and three layers of partitions 121 are built in the anaerobic generation pool 12, and the three layers o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com