Method and equipment for setting rotary-jet steel strand ground anchor

A technology for steel strands and ground anchors, which is used in construction, sheet pile walls, infrastructure projects, etc., can solve the problems of increasing installation conditions, cost and time, increasing anchoring force, etc., and achieves simple and rapid construction and environmental impact. Small, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

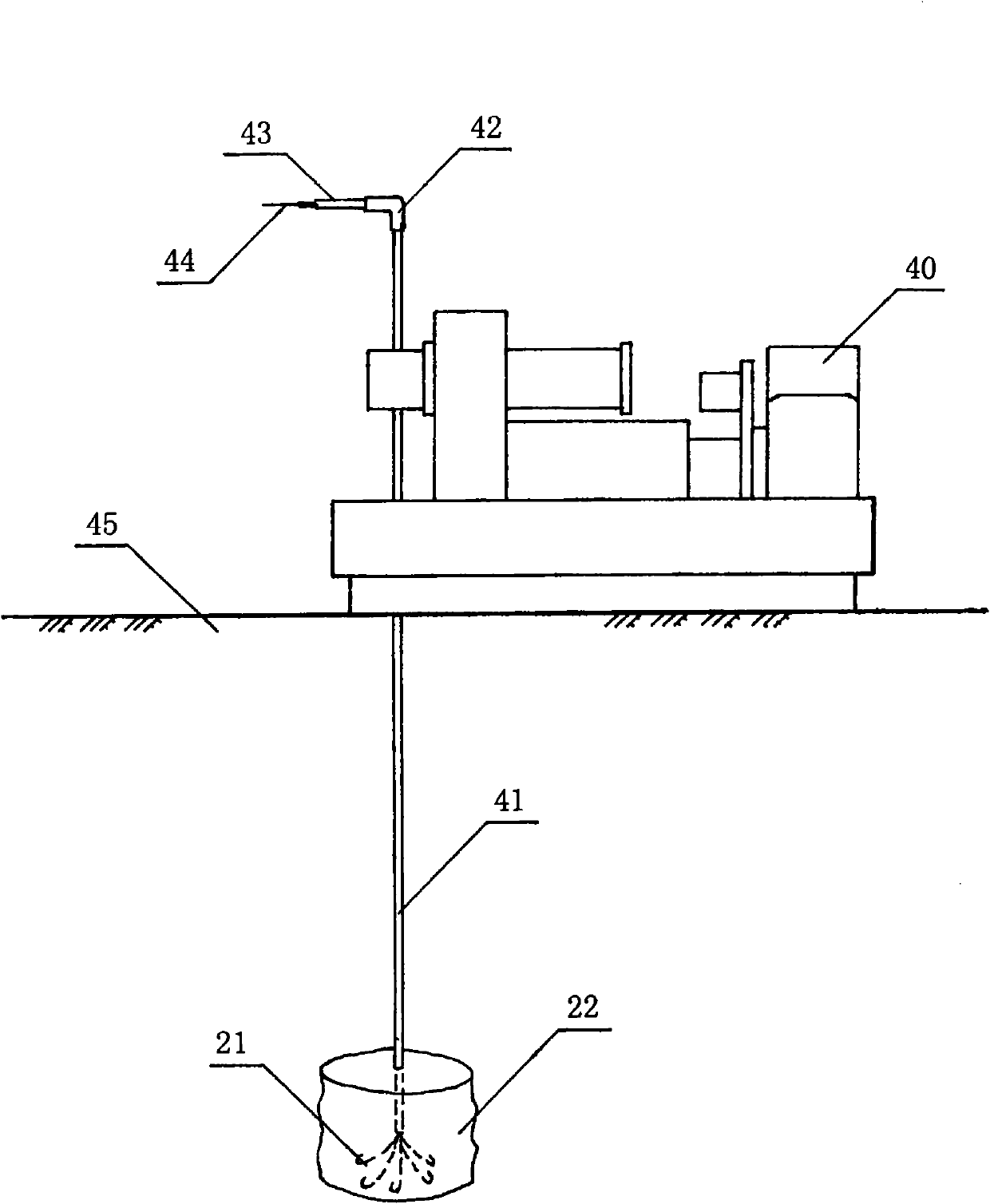

[0058] In this embodiment, the method for setting up a jet-sprayed steel strand ground anchor is as follows:

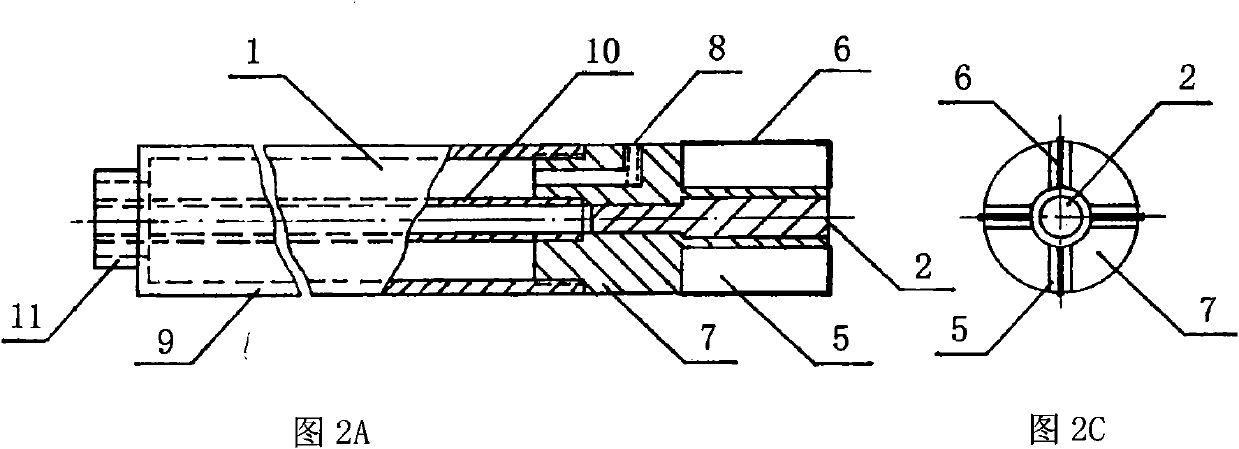

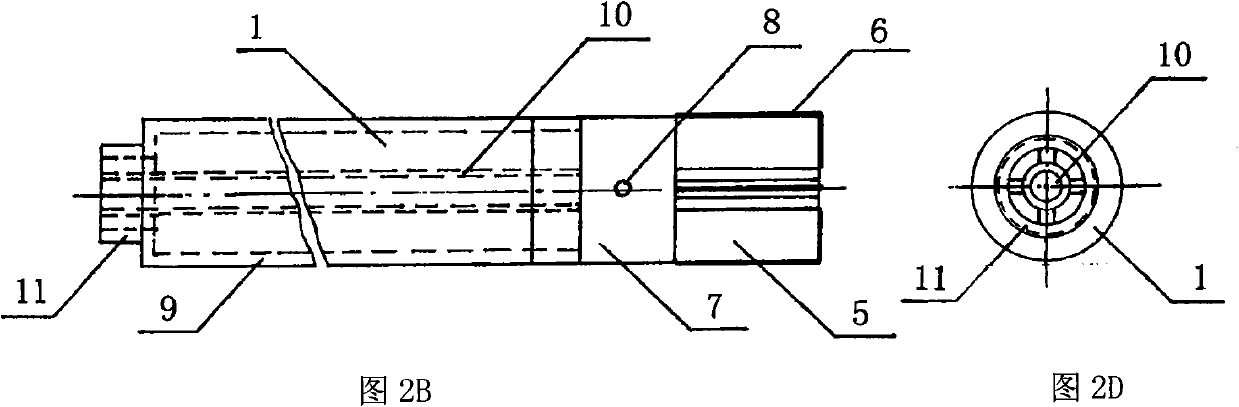

[0059] 1. See figure 1 , On the ground 45 where ground anchors need to be set up, install the drilling rig 40 and the slag cofferdam in the area where the drilling holes are piled up; install the double pipe rotary jet ground anchor bit 1 (such as Figure 2A , 2B , 2C, 2D), the double-pipe rotary jet anchor drill bit 1 has a central hole and a side shot hole 8 independently arranged;

[0060] 2. Drill according to the set drill pipe angle. While drilling, the mud pump passes through the slurry pipe 43, the infusion device 42 connected to the top of the drill pipe, the drill pipe 41, and the side of the double pipe rotary grouting ground anchor bit 1. The partial shot hole 8 sprays clay mud into the borehole for wall protection and slag removal;

[0061] 3. When the drill hole reaches the set depth, the drill bit 1 continues to rotate but does not advance, the mud pump stops...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com