Special paint remover for port infrastructure

A paint stripper and infrastructure technology, applied in the field of paint stripping, can solve the problems of prolonged construction period, multiple brushing, low paint stripping efficiency of paint strippers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

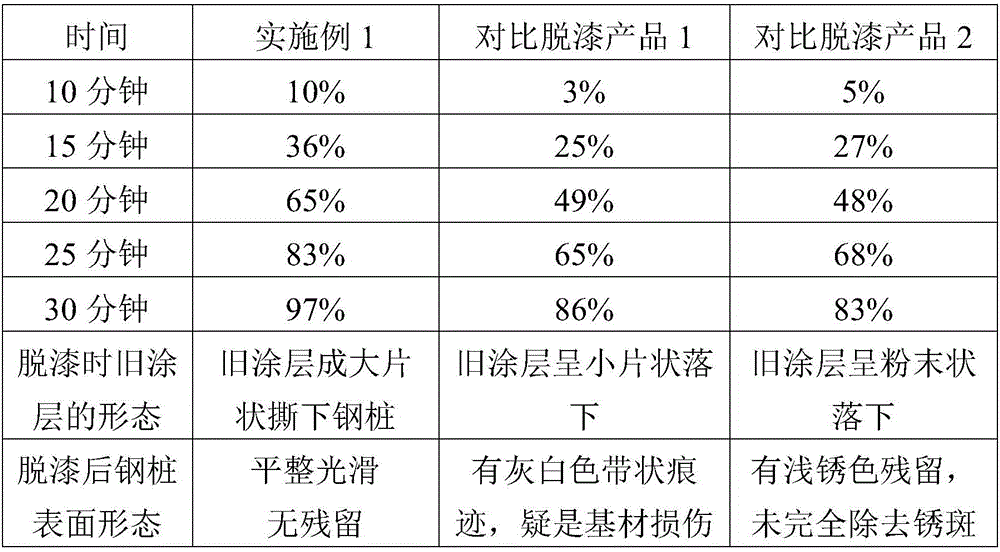

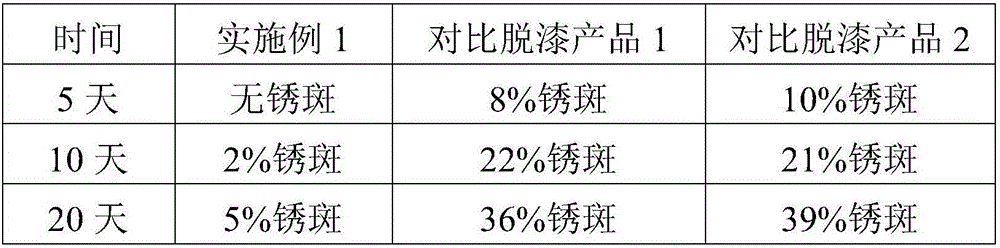

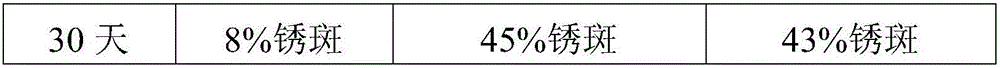

Examples

Embodiment 1

[0022] A special paint remover for port infrastructure, consisting of the following raw materials in parts by weight:

[0023] Dibasic acid ester: 25 parts; Chlorinated paraffin: 6 parts; Acrylic acid: 20 parts; Dipropylene glycol methyl ether: 10 parts; Benzyl alcohol: 7 parts; Benzotriazole: 5 parts; Formic acid: 10 parts; Boric acid: 10 parts; ethanol: 15 parts; NP-10: 3 parts; sodium gluconate: 7 parts; polyepoxysuccinic acid: 3 parts; water: 20 parts.

[0024] A preparation method of special paint remover for port infrastructure, the specific steps are as follows:

[0025] (1) After mixing polyepoxysuccinic acid, sodium gluconate, and chlorinated paraffin, stir and ultrasonically disperse at 50°C for 2 hours;

[0026] (2) Mix benzotriazole, formic acid, boric acid, ethanol, and NP-10 uniformly at 30°C, and then quickly pour the ultrasonically dispersed mixture at 50°C obtained in step (1) at a speed of 1200r / m Stir for 10 minutes and cool to 20°C;

[0027] (3) After mi...

Embodiment 2

[0030] A special paint remover for port infrastructure, consisting of the following raw materials in parts by weight:

[0031] Dibasic acid ester: 20 parts; Chlorinated paraffin: 2 parts; Acrylic acid: 15 parts; Dipropylene glycol methyl ether: 8 parts; Benzyl alcohol: 5 parts; Benzotriazole: 2 parts; Formic acid: 5 parts; Boric acid: 8 parts; ethanol: 10 parts; NP-10: 2 parts; sodium gluconate: 5 parts; polyepoxysuccinic acid: 2 parts; water: 15 parts.

[0032] A preparation method of special paint remover for port infrastructure, the specific steps are as follows:

[0033] (1) After mixing polyepoxysuccinic acid, sodium gluconate and chlorinated paraffin, stir and ultrasonically disperse at 40°C for 3 hours;

[0034] (2) Mix benzotriazole, formic acid, boric acid, ethanol, and NP-10 uniformly at 20°C, then quickly pour the ultrasonically dispersed mixture obtained in step (1) at 40°C, at a speed of 800r / m Stir for 20 minutes and cool to 10°C;

[0035] (3) After mixing dib...

Embodiment 3

[0038] A special paint remover for port infrastructure, consisting of the following raw materials in parts by weight:

[0039] Dibasic acid ester: 22 parts; Chlorinated paraffin: 5 parts; Acrylic acid: 18 parts; Dipropylene glycol methyl ether: 9 parts; Benzyl alcohol: 6 parts; Benzotriazole: 4 parts; Formic acid: 7 parts; Boric acid: 9 parts; ethanol: 13 parts; NP-10: 2.5 parts; sodium gluconate: 6 parts; polyepoxysuccinic acid: 2.5 parts; water: 18 parts.

[0040] A preparation method of special paint remover for port infrastructure, the specific steps are as follows:

[0041] (1) After mixing polyepoxysuccinic acid, sodium gluconate, and chlorinated paraffin, stir and ultrasonically disperse at 45°C for 2.5 hours;

[0042] (2) Mix benzotriazole, formic acid, boric acid, ethanol, and NP-10 uniformly at 25°C, and then quickly pour the ultrasonically dispersed mixture at 45°C obtained in step (1), at a speed of 1000r / m Stir for 15 minutes and cool to 15°C;

[0043] (3) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com