Deep-well oil-extraction external flow-channel direct and reverse circulation freely-throwing jet injector oil production method and device

A technology of reverse circulation and external flow channel, applied in the directions of jet pump, production fluid, non-displacement pump, etc., can solve the problems of easy-buried packer, oil well accident, inapplicable oil well, etc., to improve theoretical production and flow channel area. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

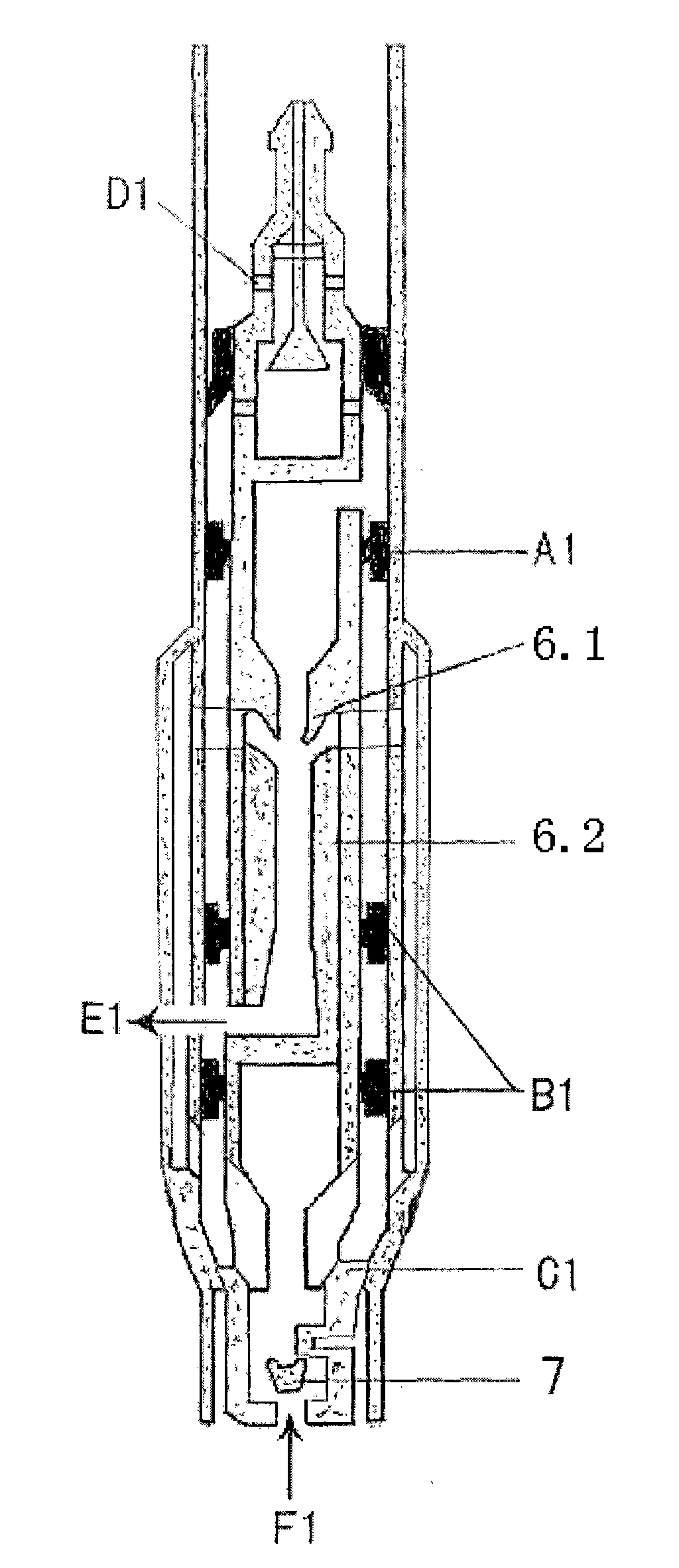

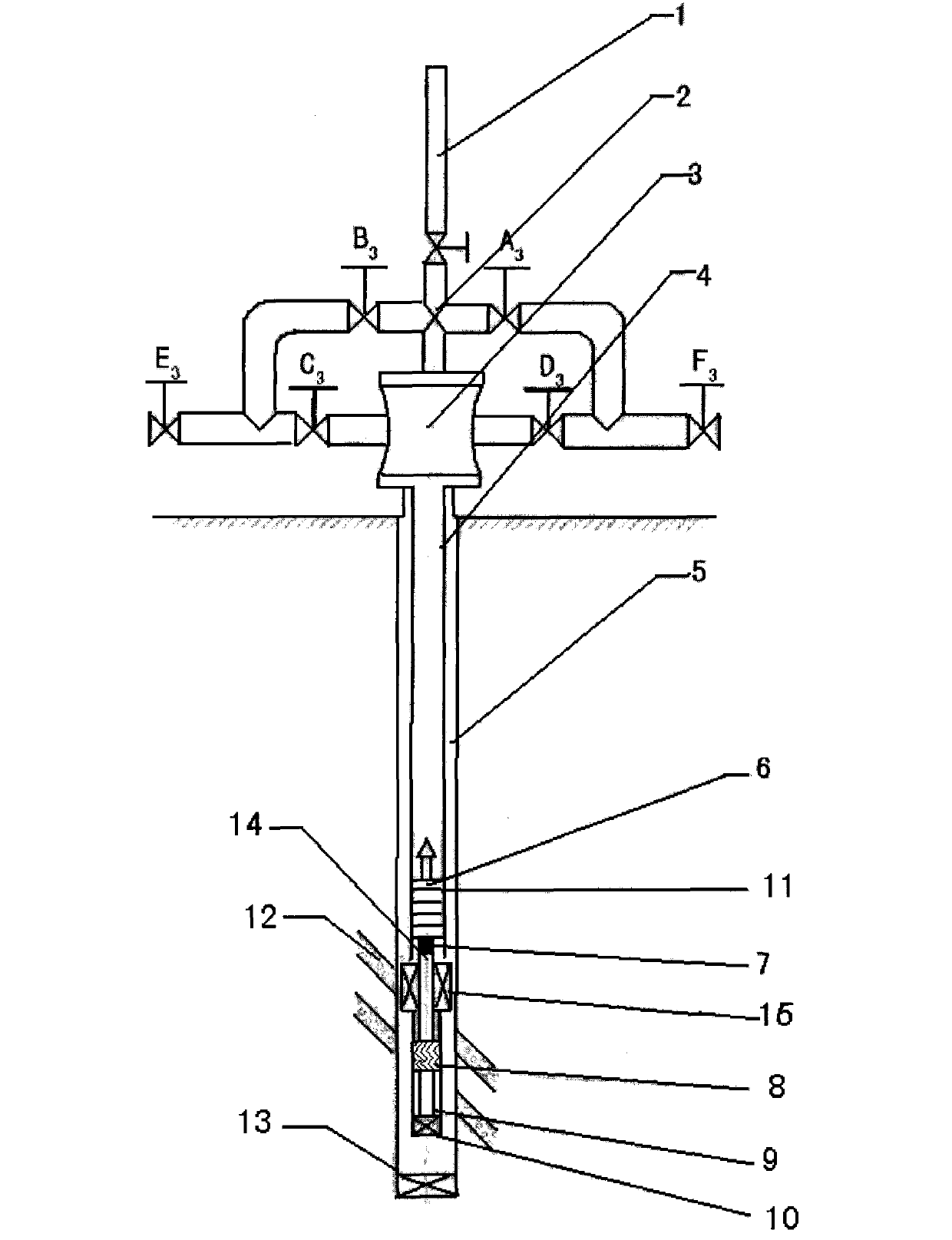

[0031] Embodiment 1: (with reference to attached image 3 ), by connecting a single oil pipe at the lower part of the wellhead device, the lower end of the oil pipe is connected with a pump barrel with an external flow channel, and a pump core (divided into positive and negative circulation pump cores) is installed in the pump barrel with an external flow channel. Install fixed reel. The combined packer and double tailpipe are connected under the pump barrel with external flow channel. The inner tailpipe is a small-diameter pipe to increase the liquid flow rate.

[0032] When positive circulation is required for oil well production, the power fluid flow channel and the pump core string are the same oil pipe. The power fluid is transferred from the downhole tubing to the positive circulation pump core in the pump barrel with an external flow channel to make the pump core work, and the pump core sucks the formation fluid into the pump core through the external flow channel of t...

Embodiment 2

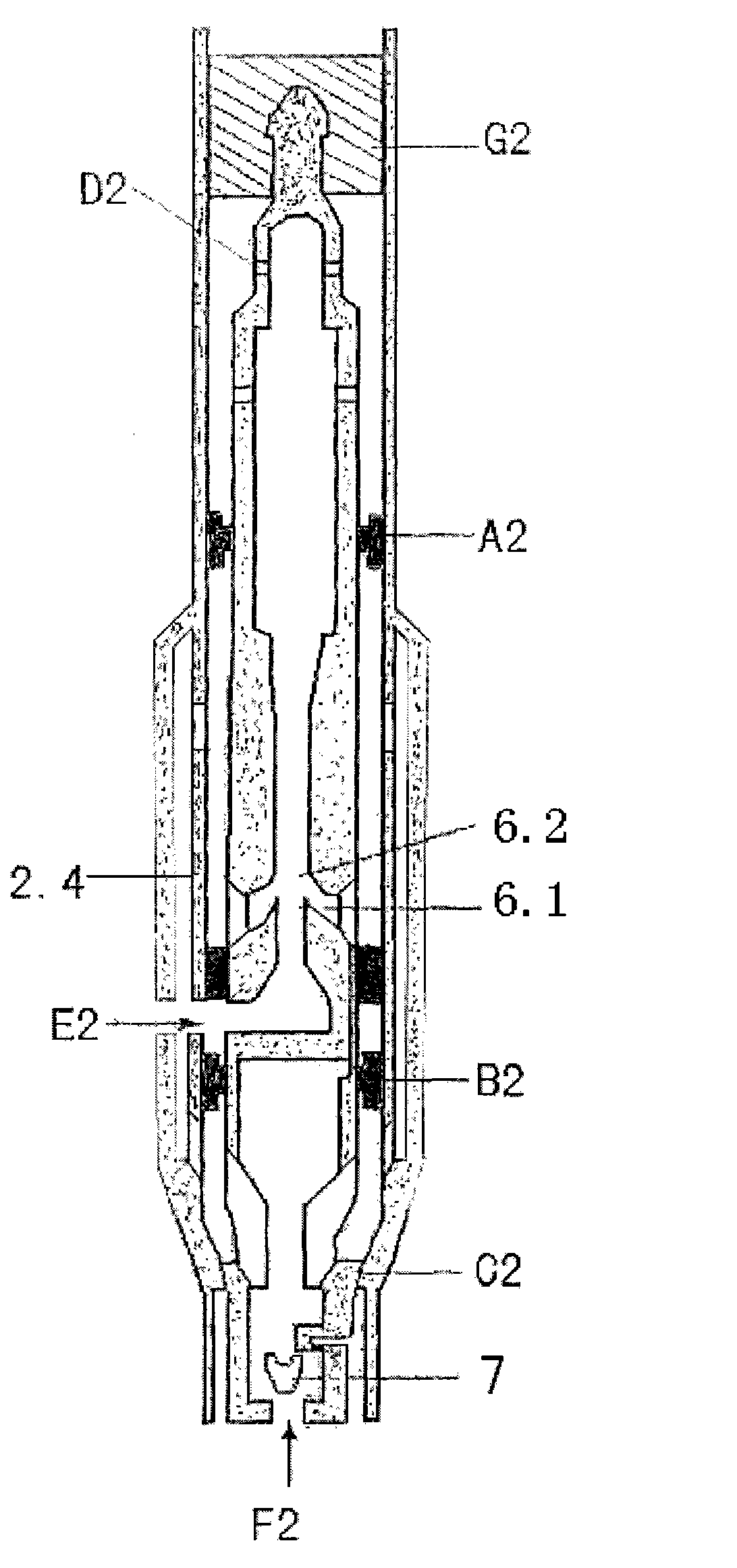

[0037] Embodiment 2: (referring to attached Figure 4 ): By connecting the parallel double oil pipes at the lower part of the wellhead device, the lower end of the parallel double oil pipes; the pump barrel with external flow channels, and the pump core installed in the pump barrel with external flow channels (divided into positive and negative circulation pump cores) . Install and fix valve under the pump core. The tubing anchor and double tail pipes are connected under the pump barrel with external flow channels, and the inner tail pipes are small-diameter pipes to increase the liquid flow rate. The middle of the outer tailpipe is connected to the sand leakage pipe, and the bottom end is the tail plug.

[0038] When positive circulation is required for oil well production, the power fluid channel is put into the pump core tubing. Put the power fluid from the pump pipe to the positive circulation pump core in the pump barrel with an external flow channel to make the pump c...

Embodiment 3

[0044] Embodiment 3: with reference to attached Figure 5 , by connecting concentric double oil pipes at the lower part of the wellhead device, the lower end of the inner oil pipes of the concentric double oil pipes is connected with a pump barrel with an external flow channel, and a jet pump is installed in the pump barrel with an external flow channel (divided into positive and negative pump cores) , Install and fix the valve under the pump core. An inner sealer and a double tailpipe are installed between the bottom of the pump barrel with an external flow channel and the outer oil pipe. The inner tailpipe is a small diameter tube that increases the liquid flow rate. The middle of the outer tailpipe is connected to the sand leakage pipe, and the bottom end is the tail plug.

[0045] When positive circulation is required for oil well production, the power fluid channel is the pump core tubing-inner tubing. Put the power fluid from the inner oil pipe to the positive circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com