Rapid extracting method for structure light welding seam image characteristic points

An image feature point and feature point extraction technology, applied in image analysis, image data processing, using optical devices, etc., can solve the problem that the processing speed cannot meet real-time processing, etc., and meet the requirements of reconfigurability and real-time performance. , the effect of improving the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the method of the present invention, further description will be given below in conjunction with the accompanying drawings and embodiments.

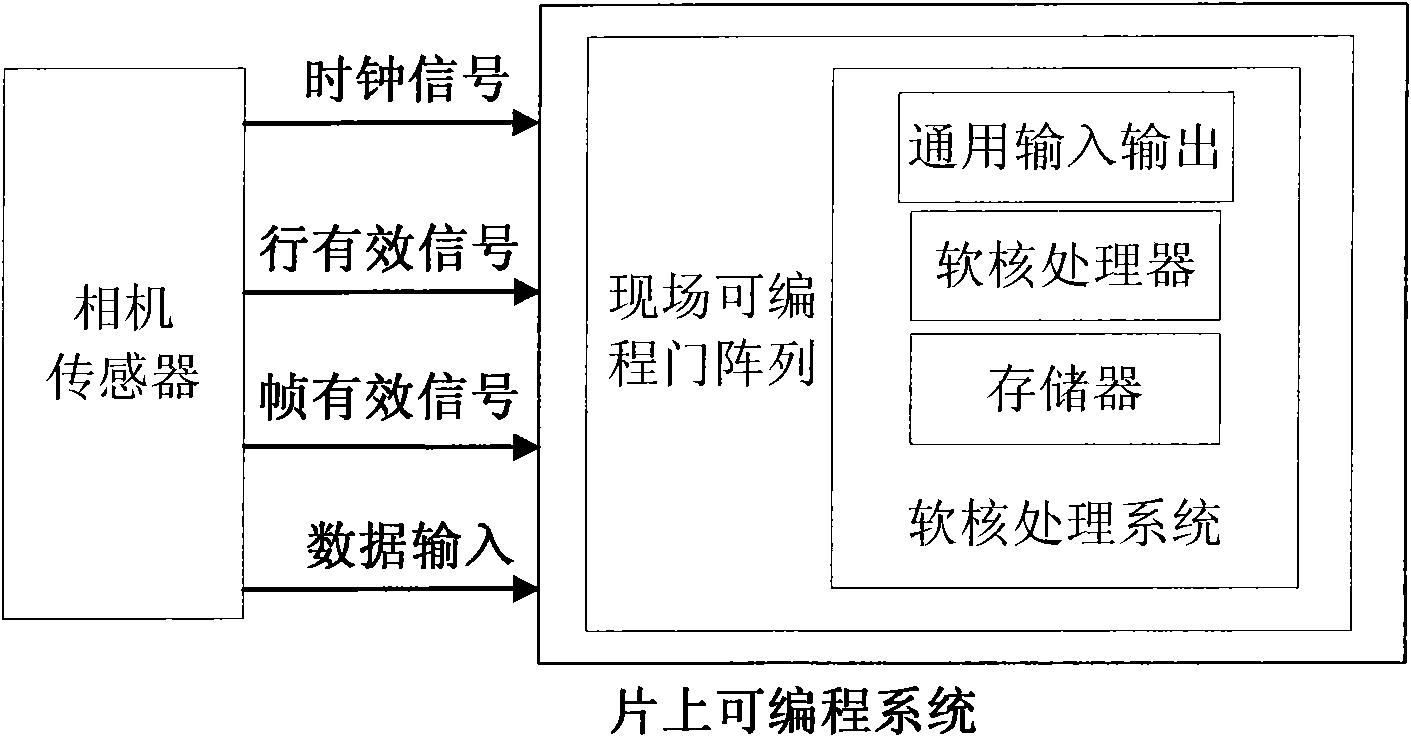

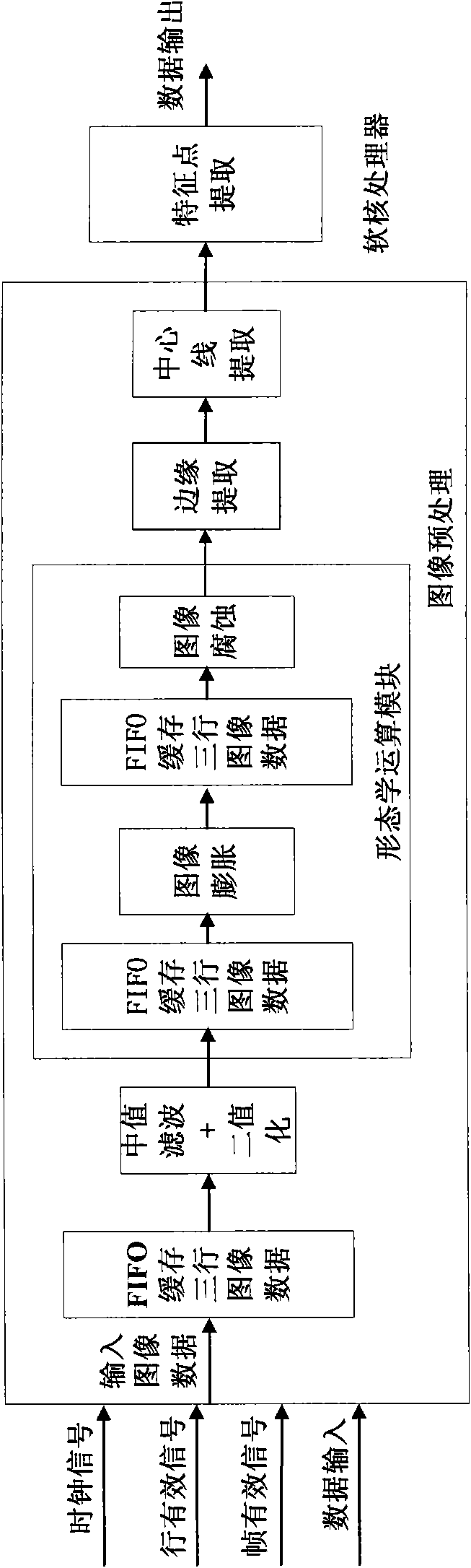

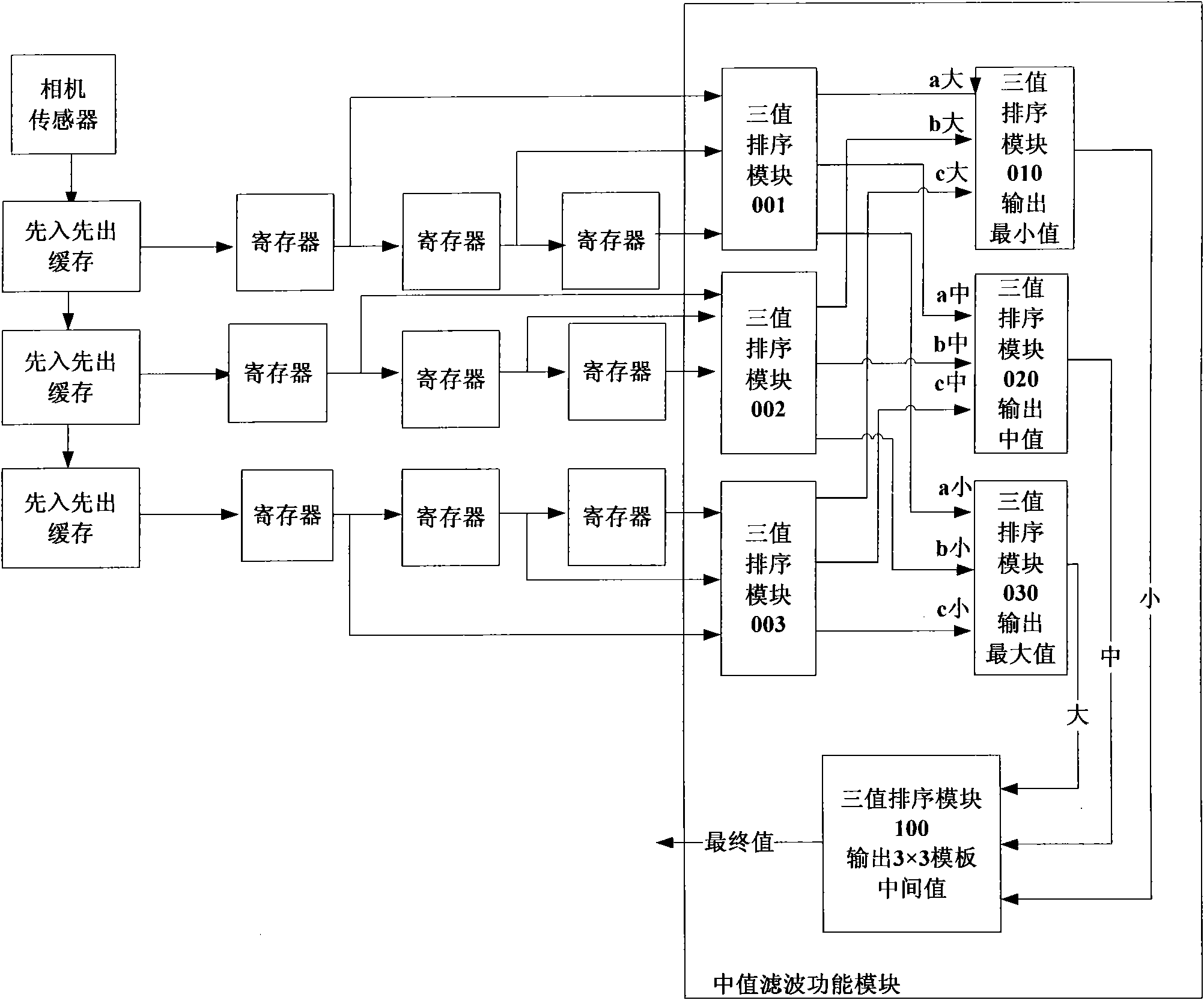

[0025] The method for quickly extracting feature points of structured light weld images based on SOPC in the present invention is realized by connecting an on-chip programmable system SOPC with a camera sensor for image collection, and performing subsequent image processing on the image collected by the camera sensor. The camera sensor is connected to the on-chip programmable system SOPC through "clock signal", "line valid signal", "frame valid signal" and "data input signal". Wherein the on-chip programmable system SOPC involved in the present invention is mainly made of 32-bit MicroBlaze soft-core processing system of Field Programmable Gate Array FPGA hardware and embedded operation, figure 1 A graph is composed for the structure, so as to realize software and hardware co-processing and improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com