Method for manufacturing P-type metal oxide semiconductor

An oxide semiconductor and metal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low BVds of PMOS, PMOS damage, easy to be broken down, etc., to improve the source-drain breakdown voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

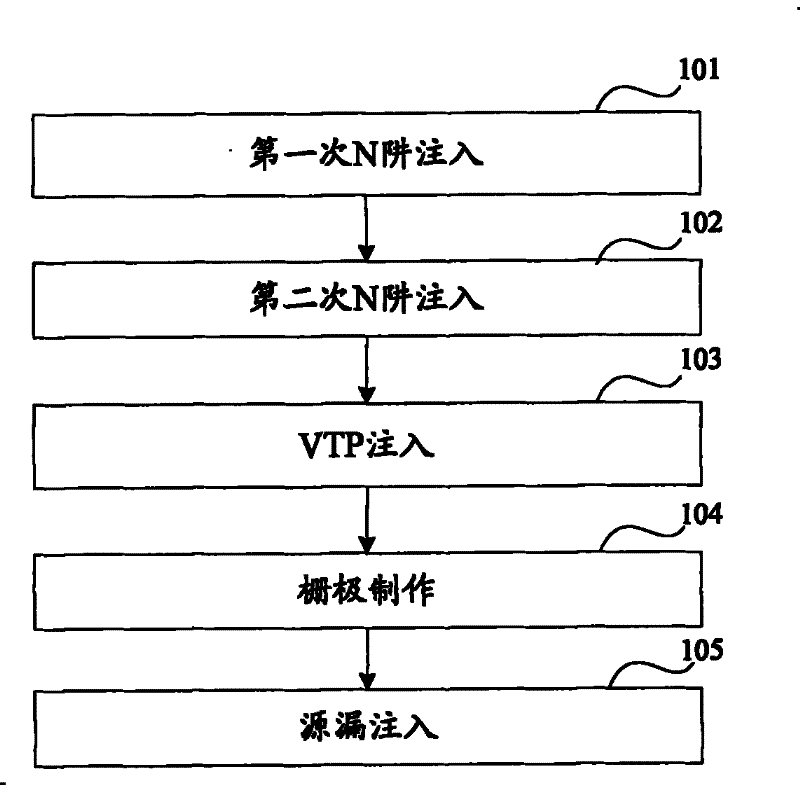

[0019] In order to improve the breakdown voltage of P-type metal oxide semiconductors, the embodiment of the present invention proposes a method for manufacturing P-type metal oxide semiconductors. The main realization principle, specific implementation process and its The corresponding beneficial effects that can be achieved are described in detail.

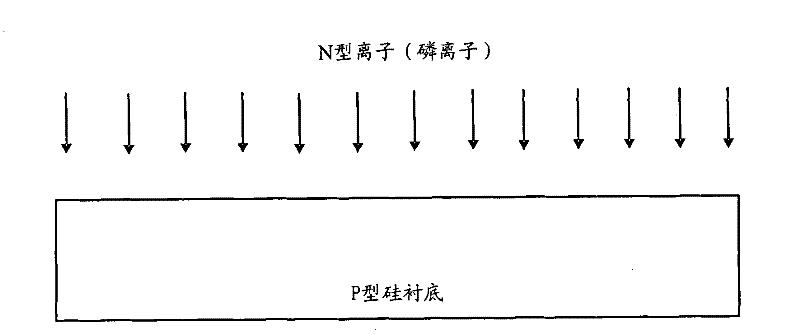

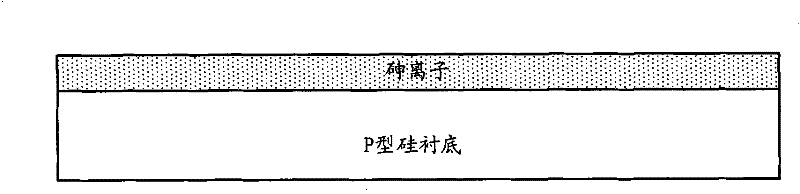

[0020] Before implementing the embodiment of the present invention, the traditional manufacturing process of PMOS was studied, and it was found that the process of well implantation has a key influence on the source-drain breakdown voltage BVds of PMOS, because the process of well implantation is directly related to the ion concentration on the surface of the PMOS channel Generally, the lower the ion concentration on the channel surface, the faster the carrier holes on the PMOS channel surface will decrease with the increase of the applied gate voltage Vg, and correspondingly, the faster the electrons will accumulate, so the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com