Heat radiating system for battery pack

A heat dissipation system and battery pack technology, applied in the direction of fuel cell heat exchange, secondary batteries, fuel cell additives, etc., can solve the problems of poor economy, high use cost, large water flow damping, etc., and achieve good heat dissipation effect and recycling Environmental protection and energy saving, solve the effect of heat dissipation and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

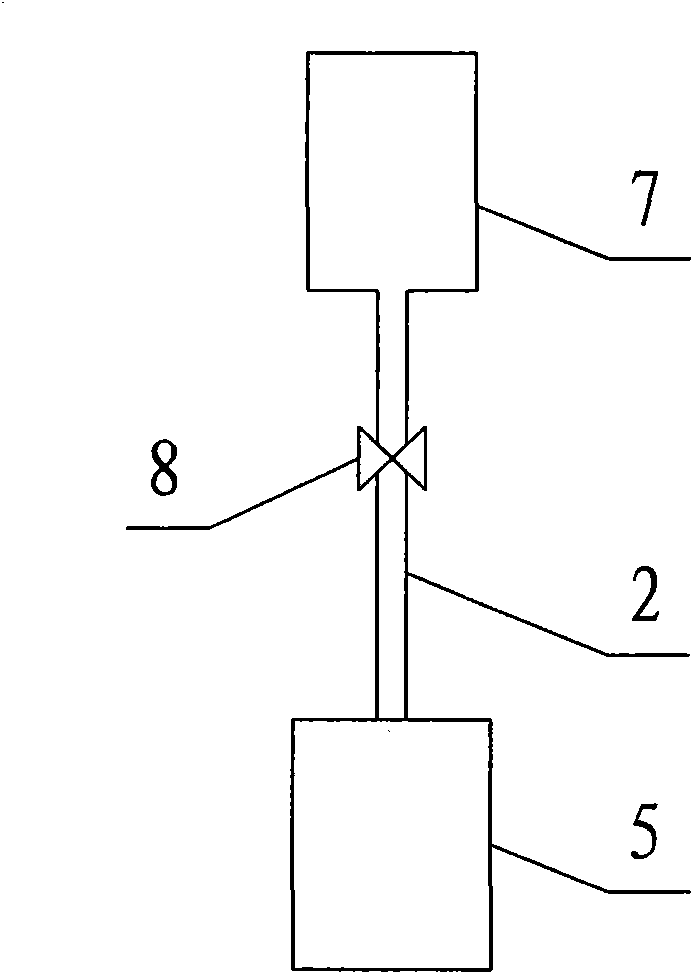

[0018] Example 1 as figure 1 As shown, the heat dissipation system of the battery pack includes a compressed gas supply source and a gas transmission pipeline, wherein the compressed gas supply source is the gas storage tank 7, the input end of the gas transmission pipeline 2 is connected to the gas storage tank, and the output end is connected to the battery box where the power battery pack is placed. 5. A one-way electric control solenoid valve 8 is installed on the gas pipeline. When working, the working compressed gas in the gas storage tank is sent to the battery box through the gas transmission pipeline to dissipate heat for the power battery pack; the pulsation control one-way electronically controlled solenoid valve can control the gas transmission state of the gas storage tank.

Embodiment 2

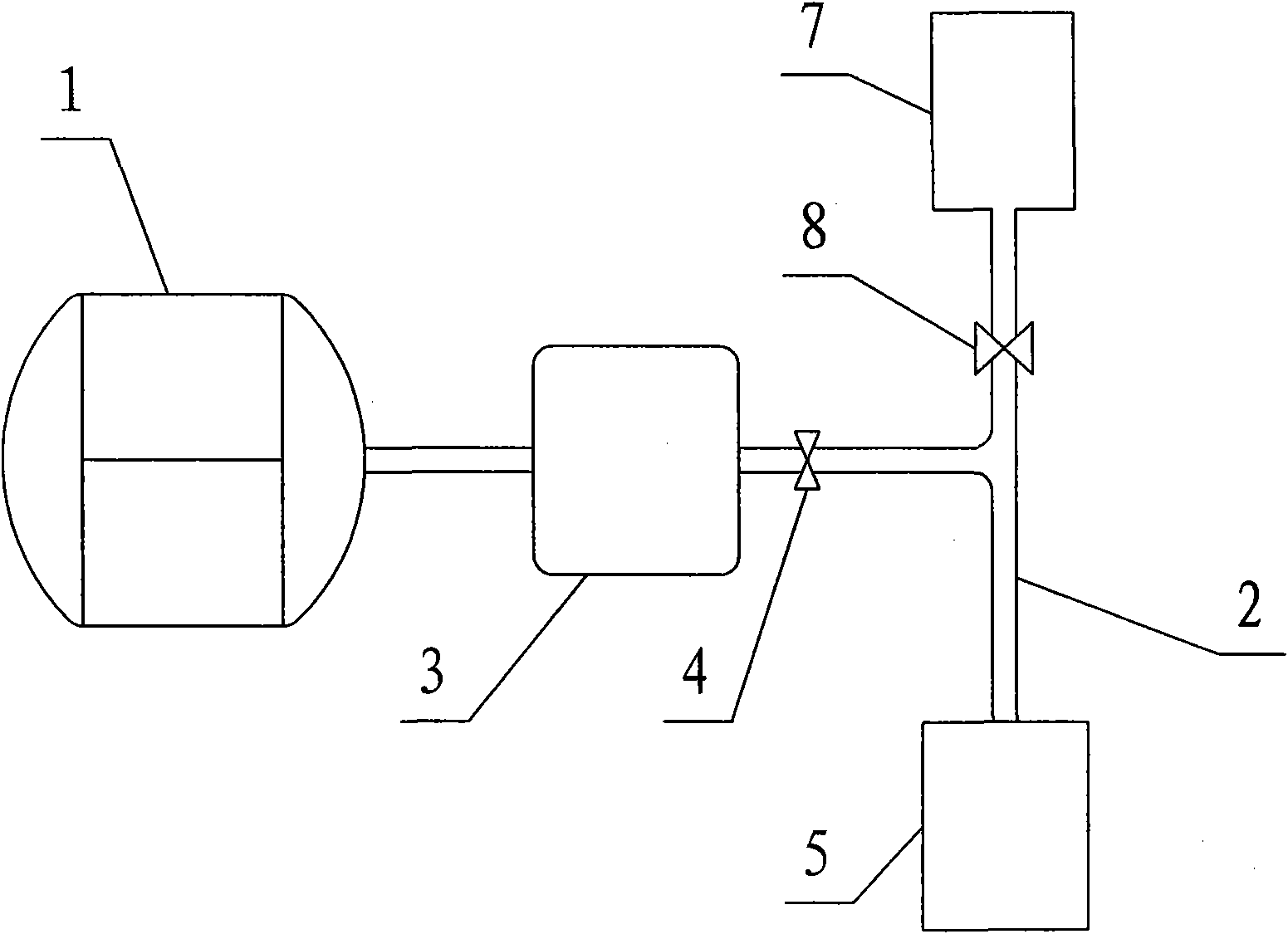

[0019] Example 2 as figure 2 As shown, the heat dissipation system of the battery pack includes a compressed gas supply source and a gas transmission pipeline 2, wherein the compressed gas supply source includes the exhaust of the brake master valve 3 and the gas supply of the air storage tank 7, and the input end of the gas transmission pipeline is divided into two branches, respectively. Connect the exhaust joint on the main brake valve 3 and the air delivery joint on the air storage tank 7, the branch air transmission pipeline connected with the air storage tank 7 is equipped with a one-way electric control solenoid valve 8, and the branch transmission line connected with the main brake valve A one-way valve 4 is installed on the gas pipeline, and the output end of the gas pipeline is connected to the battery box 5 where the power battery pack is placed. When working, the compressed gas discharged from the two gas sources is sent to the battery box through the gas pipeline...

Embodiment 3

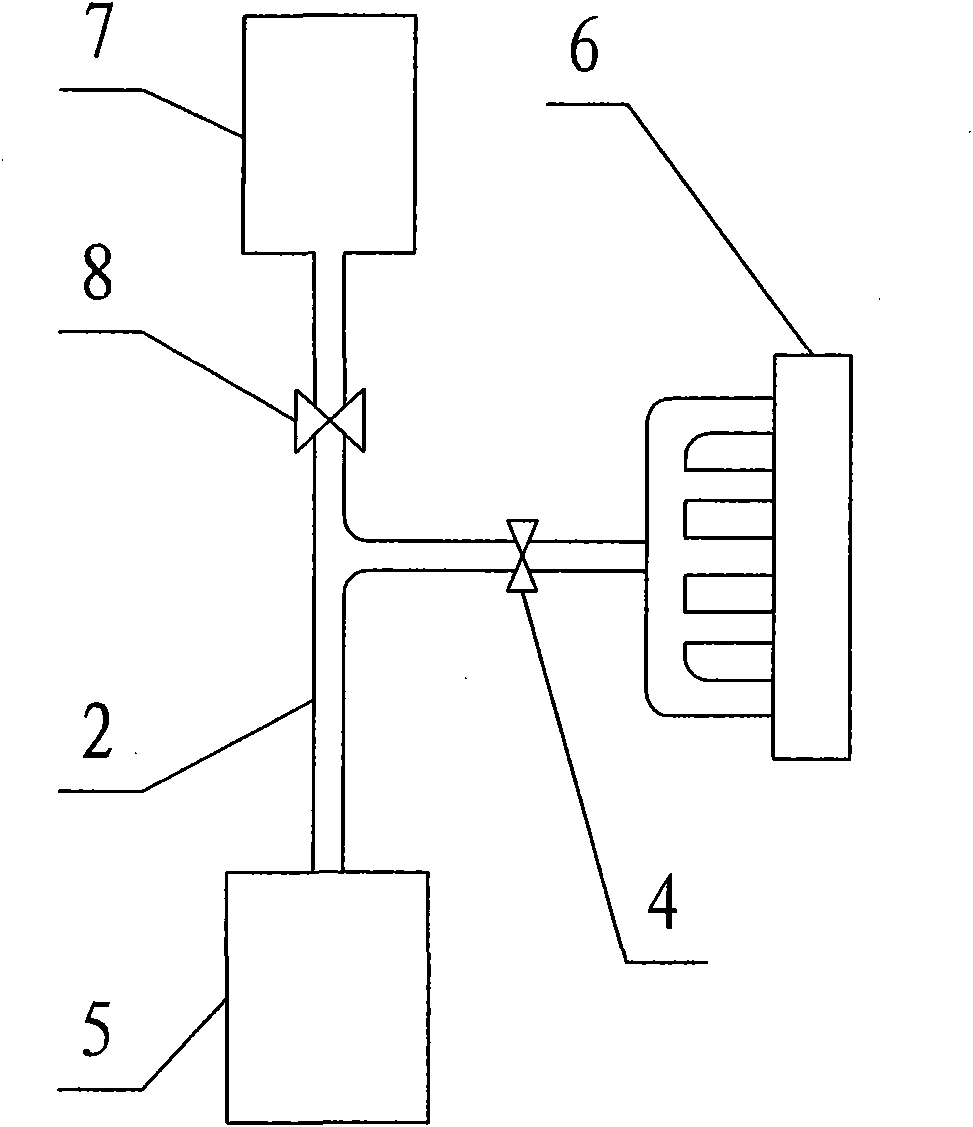

[0020] Example 3 as image 3 As shown, the heat dissipation system of the battery pack includes a compressed gas supply source and an air pipeline 2, wherein the compressed gas supply source includes an air storage tank 7 for gas supply and an electronically controlled air suspension system main valve 6 for exhaust, and the input end of the gas pipeline is branched Connect the exhaust joint on the main valve 6 of the electronically controlled air suspension system and the air delivery joint on the air storage tank 7 respectively, and the branch air delivery pipeline connected to the air storage tank 7 is equipped with a one-way electric control solenoid valve 8, which is connected with the air storage tank 7. A one-way valve 4 is installed on the branch air pipeline connected to the main valve of the electronic control air suspension system, and the output end of the air pipeline is connected to the battery box 5 where the power battery pack is placed. When working, the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com