Plasma generating device

A technology for generating device and plasma, applied in the field of ions, can solve the problems of inapplicability of material surface modification and inability to exist in a large range outside, and achieve the effect of increasing electron density and increasing the number of cations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

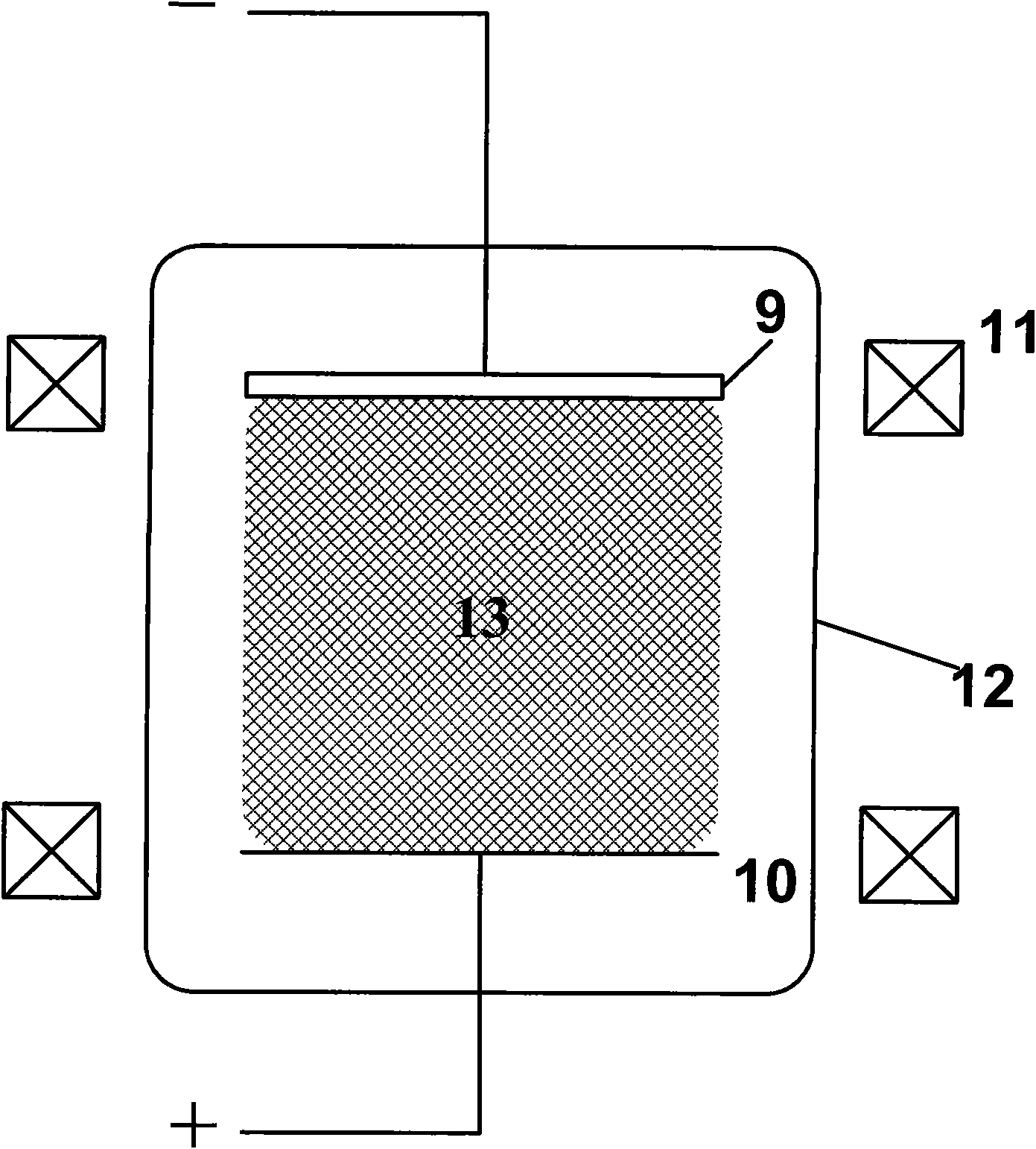

[0027] The structure of the plasma generating device in this embodiment is as follows image 3 As shown, the main part is composed of a cylindrical shell 12 , a pair of Helmholtz coils 11 , a linear hollow electrode 9 and a circular anode 10 . The Helmholtz coil 11 is placed coaxially with the casing 12, the opening of the hollow electrode 9 is opposite to the anode 10, the cathode 9 is arranged parallel to the anode 10, the center of the electrode is also at the axial center of the casing, and the inside of the casing 12 is a vacuum chamber.

[0028] The working principle of the hollow cathode is as follows Figure 4 As shown, its structure is as Figure 5 to Figure 7 As shown, an opening slightly smaller than the diameter of the round tube is drawn on one side of the metal round tube. The width of the opening is 0.8 to 0.95 times the diameter of the inner wall of the hollow metal tube. The inner wall of the active cathode should be polished accordingly. , to avoid spark di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com