Granular soil spraying machine

A technology of soil and aggregates, applied in the direction of soil lifting machinery, agricultural machinery and implements, applications, etc., can solve the problems of poor water holding capacity, fertilizer retention and stability, simple equipment, low operating efficiency, etc., and achieve easy repair and maintenance , high degree of humanization, the effect of excellent aggregate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

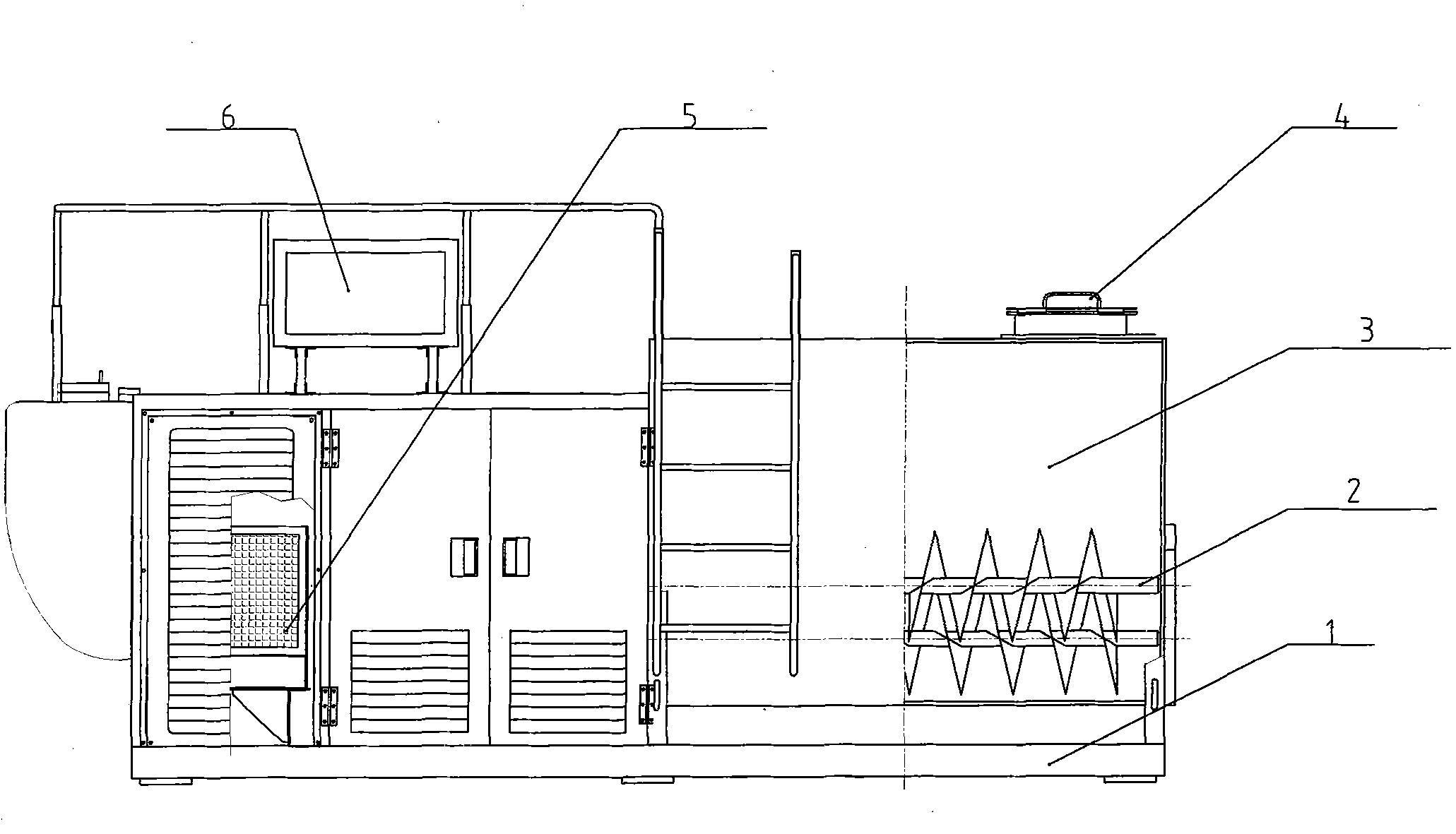

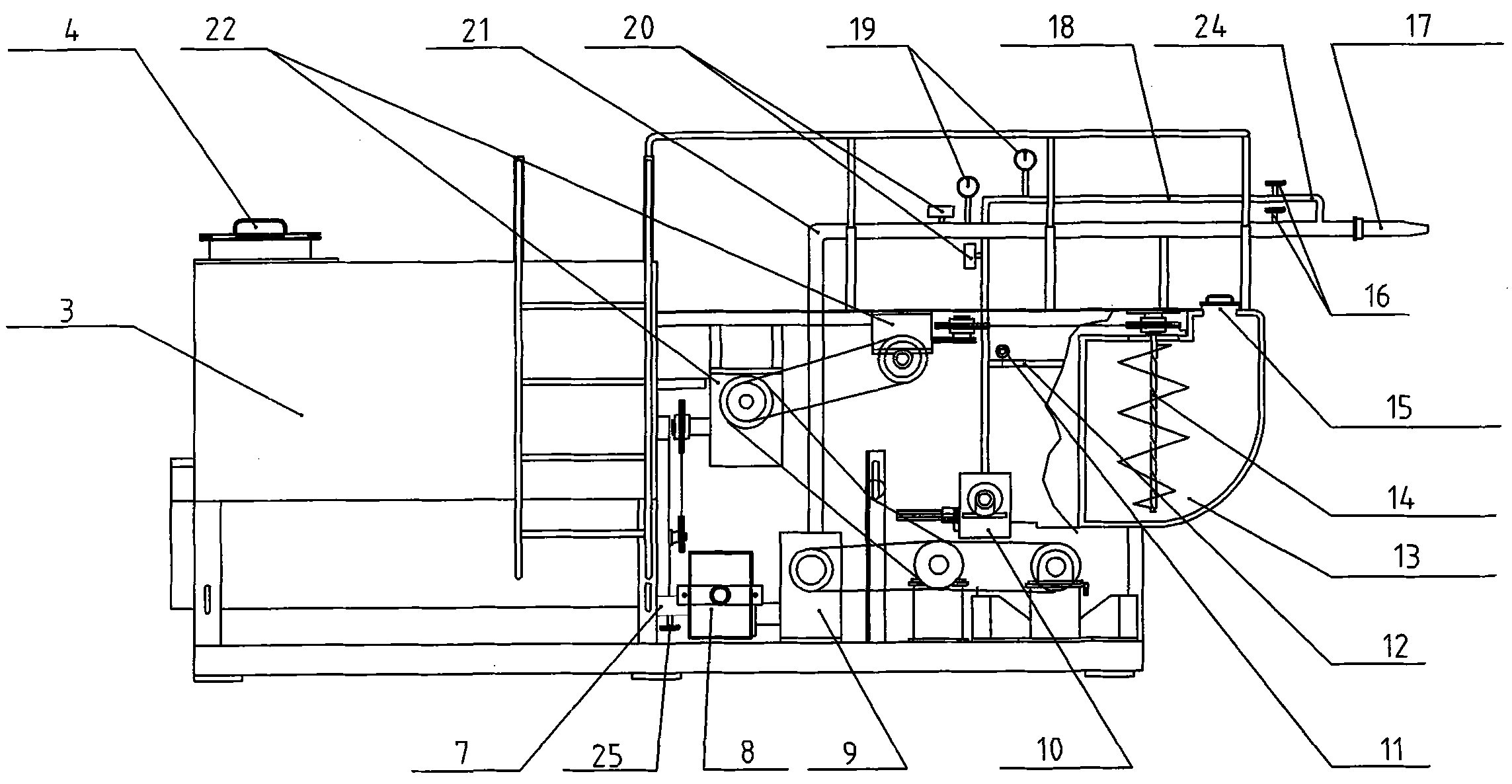

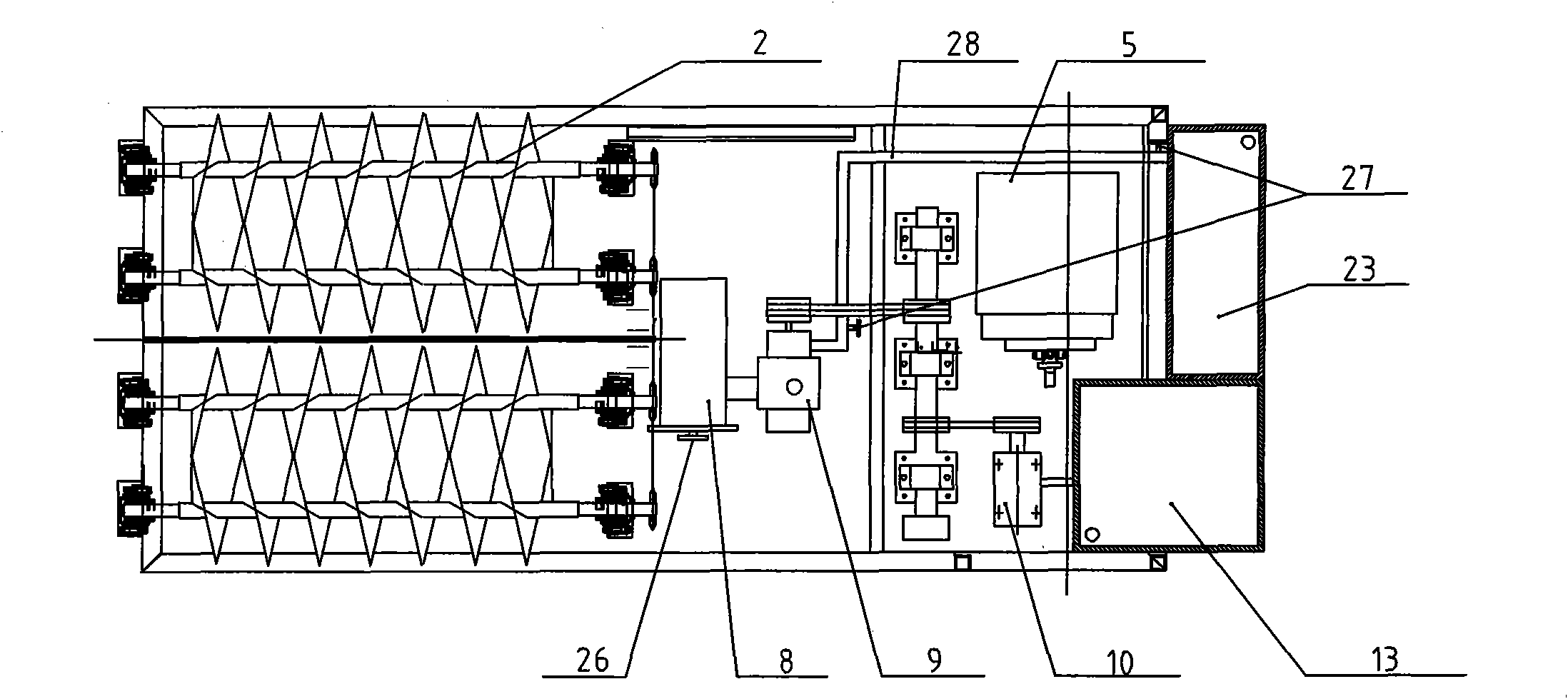

[0027] Such as figure 1 , figure 2 , image 3 As shown, the aggregate soil spraying machine of the present invention comprises frame 1, diesel engine 5, mud pump 9, mud mixing bin 3, mud stirring shaft 2, agglomerate agent pump 10, agglomerate agent mixing bin 13, agglomerate agent stirring shaft 14, Cleaning chamber 23, relay chamber 8, and transmission system, electrical control system, pipeline system, instrument display system and lubrication system

[0028] Wherein the diesel engine 5 is positioned at the left front bottom of the pellet soil spraying machine (with the soil culture medium outlet 17 as the front), the mud pump 9 and the relay chamber 8 are positioned at the middle and lower part of the equipment, and the mud mixing chamber 3 is positioned at the pellet soil spraying machine The rear half of the agglomerate agent mixing chamber 13 and the cleaning chamber 23 are positioned at the front upper part of the aggregate soil spraying machine, and the electric co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com