Multifunctional putty

A kind of atomic ash, multifunctional technology, applied in the direction of filling slurry, etc., to save repair time, excellent flexibility and adhesion, easy to apply and scrape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Step 2: Add talcum powder to the first dispersion as mentioned above, stir at 1000-1250 rpm for 20-30 minutes, until the modified organic thixotropic agent is fully activated and dispersed evenly, and add the dispersed Wetting agent, stirred for 5-10 minutes to obtain the second dispersion;

[0043] Step 3: Add precipitated barium sulfate to the second dispersion as above, stir for 10-15 minutes at a speed of 1000-1100 rpm, wash the machine, and cool while stirring until the temperature of the ash body is lower than 40 degrees , compressed and vacuumed for 5-10 minutes to obtain the main agent.

[0044] The fourth step: the main ingredient obtained in the third step above and 50% benzoyl peroxide (BPO) red paste curing agent are mixed according to the mass ratio of 100:2 to test the performance.

[0045] The working principle of the present invention is as follows: the modified unsaturated polyester resin and different powders and additives are rationally matched to pr...

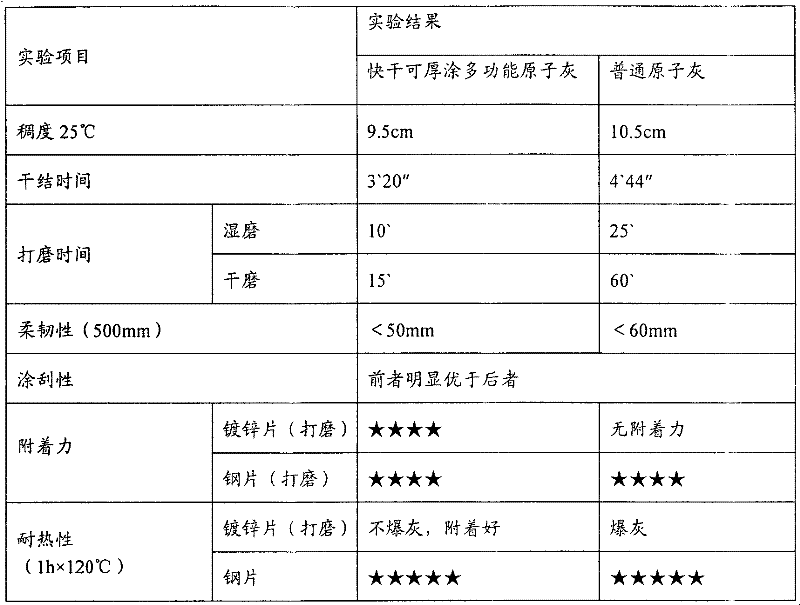

Embodiment 1

[0049] The curing agent is 50% benzoyl peroxide;

[0050] The specific preparation process steps of this example are, the first step: put the unsaturated polyester resin into the dispersion tank according to the formula amount in the above table, and add styrene, polymerization inhibitor, accelerator, thixotropic agent, anti-sedimentation agent at 700 Stirring for 8-10 minutes at a speed of rpm to obtain the first dispersion;

[0051] Step 2: Add talcum powder to the first dispersion as mentioned above, stir at 1000-1250 rpm for 20-30 minutes, until the modified organic thixotropic agent is fully activated and dispersed evenly, and add the dispersed Wetting agent, stirred for 5-10 minutes to obtain the second dispersion;

[0052] Step 3: Add precipitated barium sulfate to the second dispersion as above, stir for 10-15 minutes at a speed of 1000-1100 rpm, wash the machine, and cool while stirring until the temperature of the ash body is lower than 40 degrees , compressed and ...

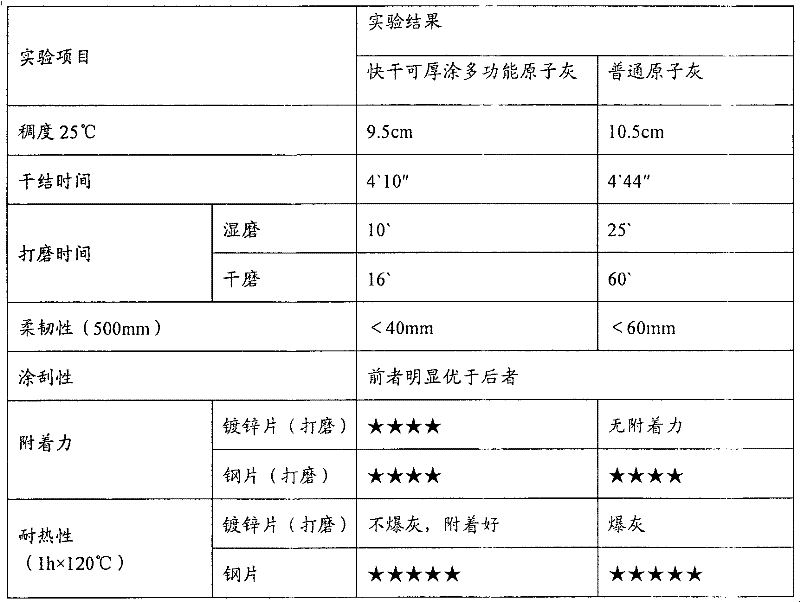

Embodiment 2

[0059] The curing agent is 50% benzoyl peroxide;

[0060] The specific preparation process steps of this example are, the first step: put the unsaturated polyester resin into the dispersion tank according to the formula amount in the above table, and add styrene, polymerization inhibitor, accelerator, thixotropic agent, anti-sedimentation agent at 700 Stirring for 8-10 minutes at a speed of rpm to obtain the first dispersion;

[0061] Step 2: Add talcum powder to the first dispersion as mentioned above, stir at 1000-1250 rpm for 20-30 minutes, until the modified organic thixotropic agent is fully activated and dispersed evenly, and add the dispersed Wetting agent, stirred for 5-10 minutes to obtain the second dispersion;

[0062] Step 3: Add precipitated barium sulfate to the second dispersion as above, stir for 10-15 minutes at a speed of 1000-1100 rpm, wash the machine, and cool while stirring until the temperature of the ash body is lower than 40 degrees , compressed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com