Preparation method of active cryptomelane

A cryptopotassium manganese ore and active technology, which is applied in the field of preparation of active cryptopotassium manganese ore, can solve problems such as difficult commercial production, high cost and high price, and achieve the effects of simple method, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

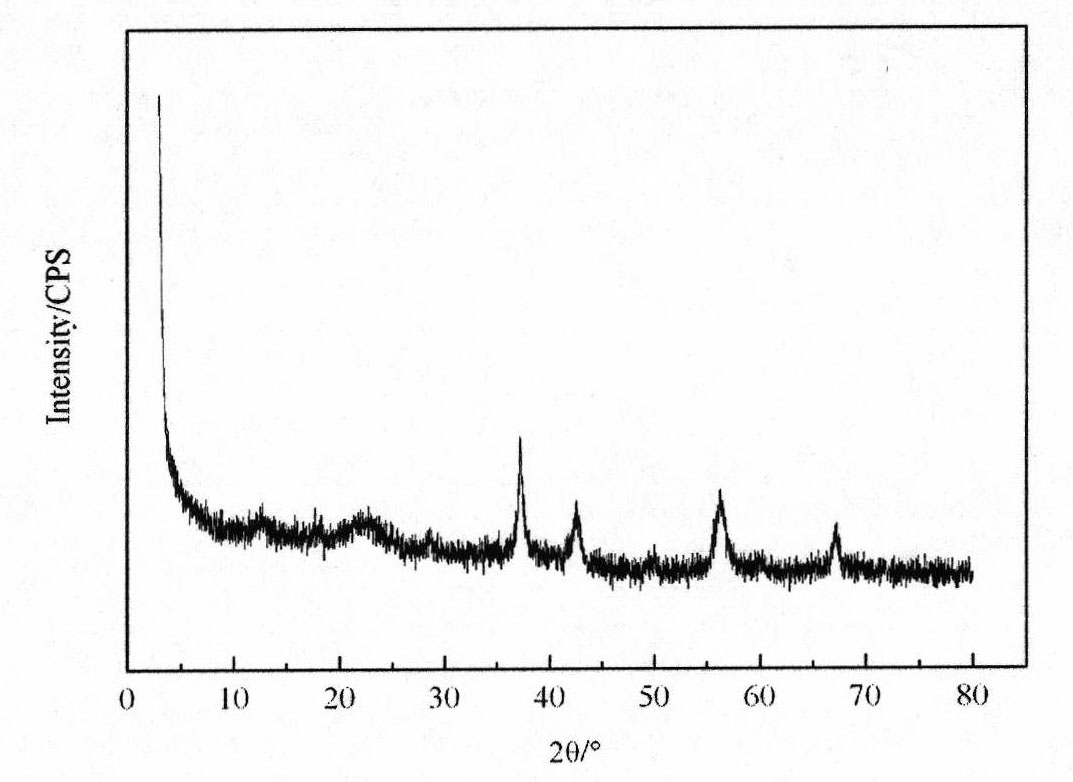

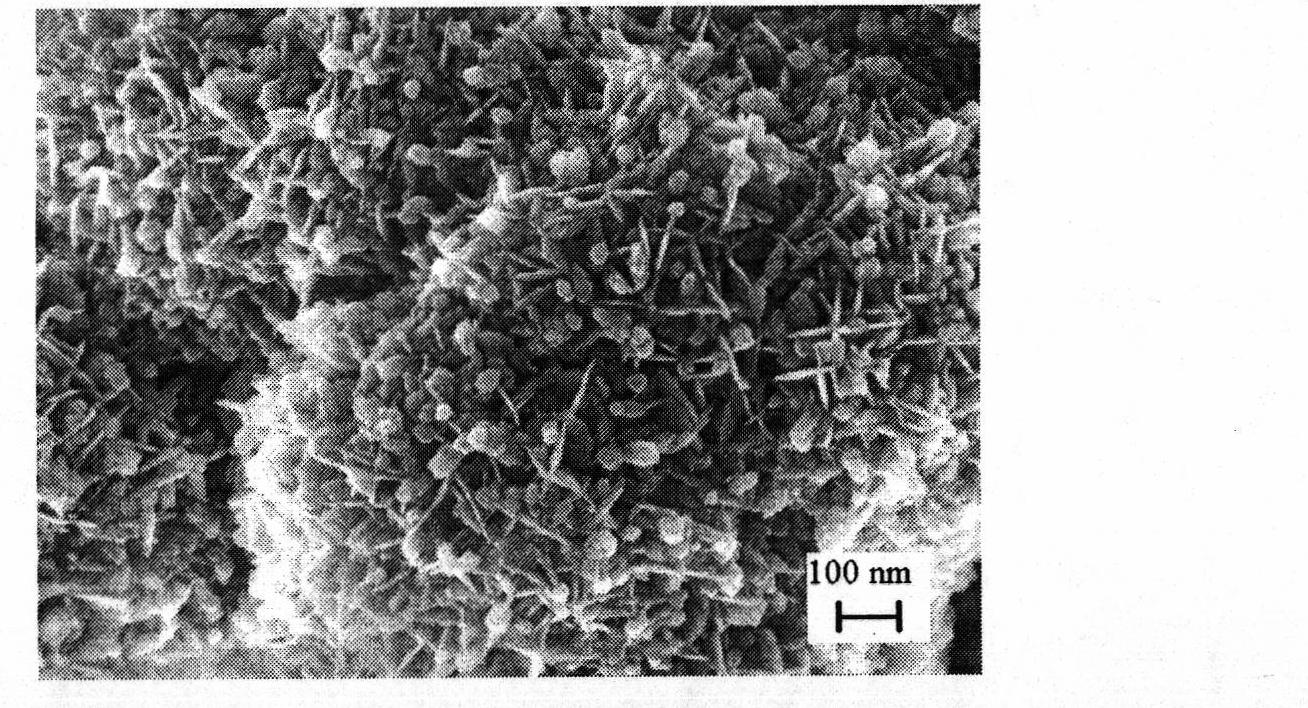

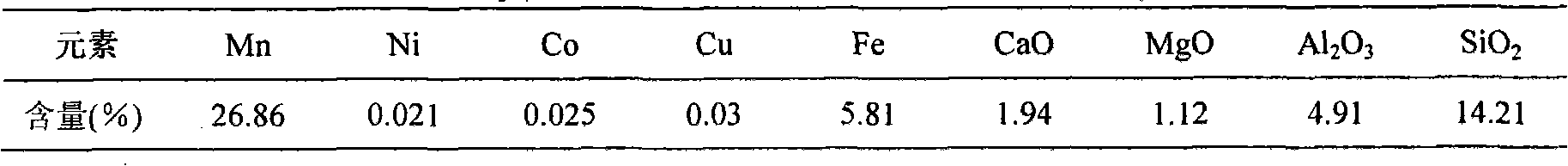

[0023] Weigh 8g of oceanic manganese nodule ammonia leaching residue, wash with deionized water for 3 times, then filter with suction, then dissolve in 0.6mol / L sulfuric acid solution, stir for 10min, mix with 43°C solution containing 11g of potassium persulfate, and use 0.5 mol / L of KOH and H 2 SO 4 Adjust the pH value of the solution to 0, then pour the mixed solution into a polytetrafluoroethylene-lined high-pressure hydrothermal kettle to about 80%, keep the hydrothermal constant temperature under an external heat source at 150°C for 24 hours, naturally cool and age for 24 hours, filter, and use Wash the filter residue with deionized water until neutral, dry it at 120°C for 16 hours, and then grind it. The XRD and SEM images of the product are shown in figure 1 , figure 2 , confirmed as nano-scale active cryptopotassium manganese ore. Using this product as a catalyst can significantly promote the degradation of methylene blue with 30% hydrogen peroxide.

Embodiment 2

[0025] Weigh 6g of oceanic manganese nodules ammonia leaching residue, wash with deionized water for 3 times, then filter with suction, then dissolve in 0.6mol / L sulfuric acid solution, stir for 10min, mix with 43°C solution containing 9g of potassium persulfate, and use 0.5 mol / L of KOH and H 2 SO 4 The pH value of the solution was adjusted to 5, and then the mixed solution was poured into a polytetrafluoroethylene-lined high-pressure hydrothermal kettle to about 80%, kept at a temperature of 120°C under an external heat source for 24 hours, naturally cooled and aged for 12 hours, filtered, and used The filter residue was washed with deionized water until neutral, dried at 120°C for 16 hours, and then ground to obtain the active cryptopotassium manganese ore product.

Embodiment 3

[0027] Weigh 8g of oceanic manganese nodule ammonia leaching residue, wash with deionized water for 3 times, then filter with suction, then dissolve in 0.6mol / L sulfuric acid solution, stir for 10min, mix with 11.2g of ammonium persulfate solution, and use 0.5mol / L of KOH and H 2 SO 4 The pH value of the solution was adjusted to 5, and then the mixed solution was poured into a polytetrafluoroethylene-lined high-pressure hydrothermal kettle to about 80%, kept at a temperature of 160°C under an external heat source for 6 hours, naturally cooled and aged for 24 hours, filtered, and used The filter residue was washed with deionized water until neutral, dried at 120°C for 16 hours, and then ground to obtain the active cryptopotassium manganese ore product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com