Non-woven fabric for manufacturing Ni-MH battery sulfonated membrane, Ni-MH battery sulfonated membrane and manufacturing method thereof

A nickel-metal hydride battery and non-woven fabric technology, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of non-woven substrate cloth surface extension, technical difficulties and complicated processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

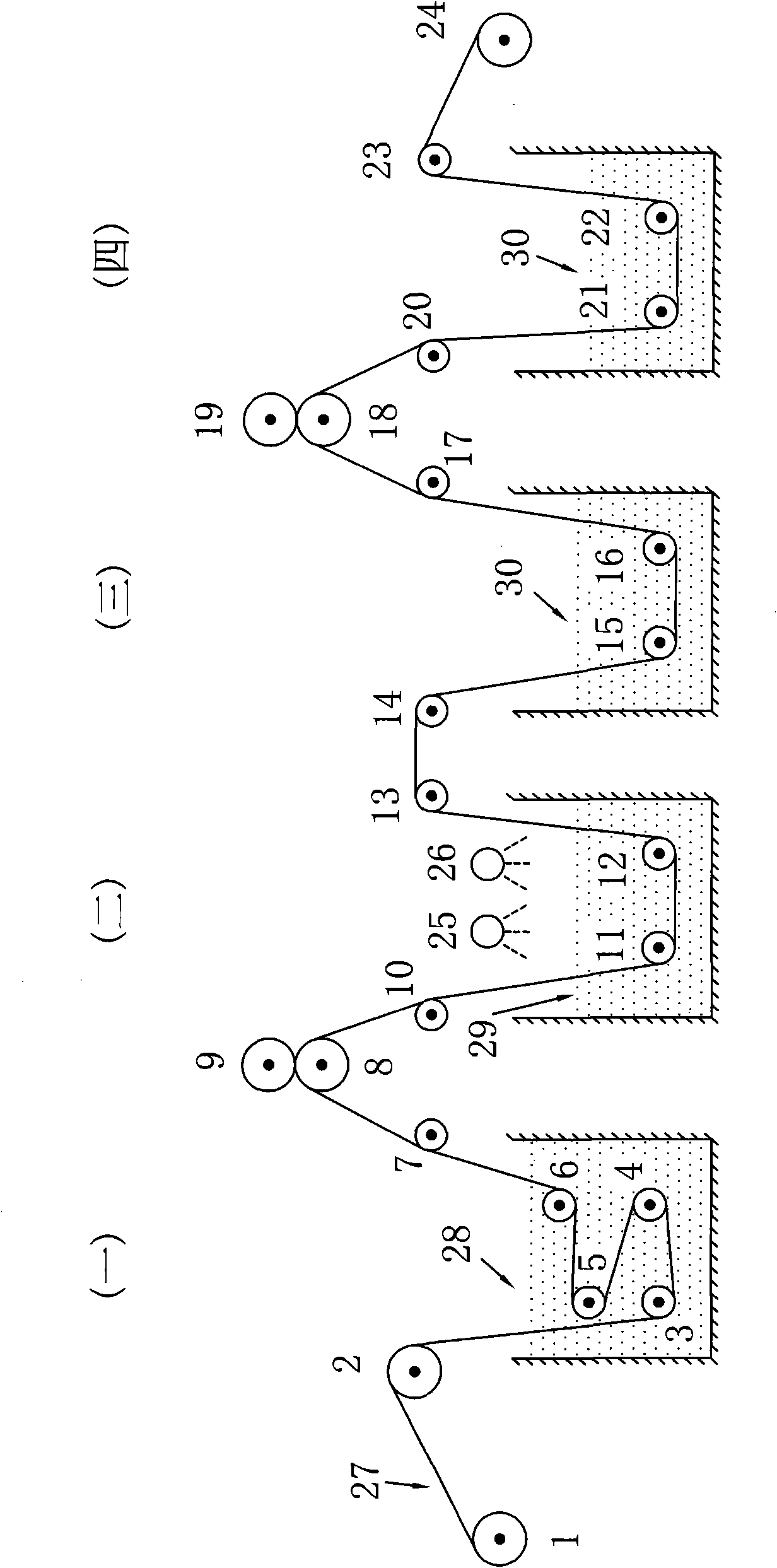

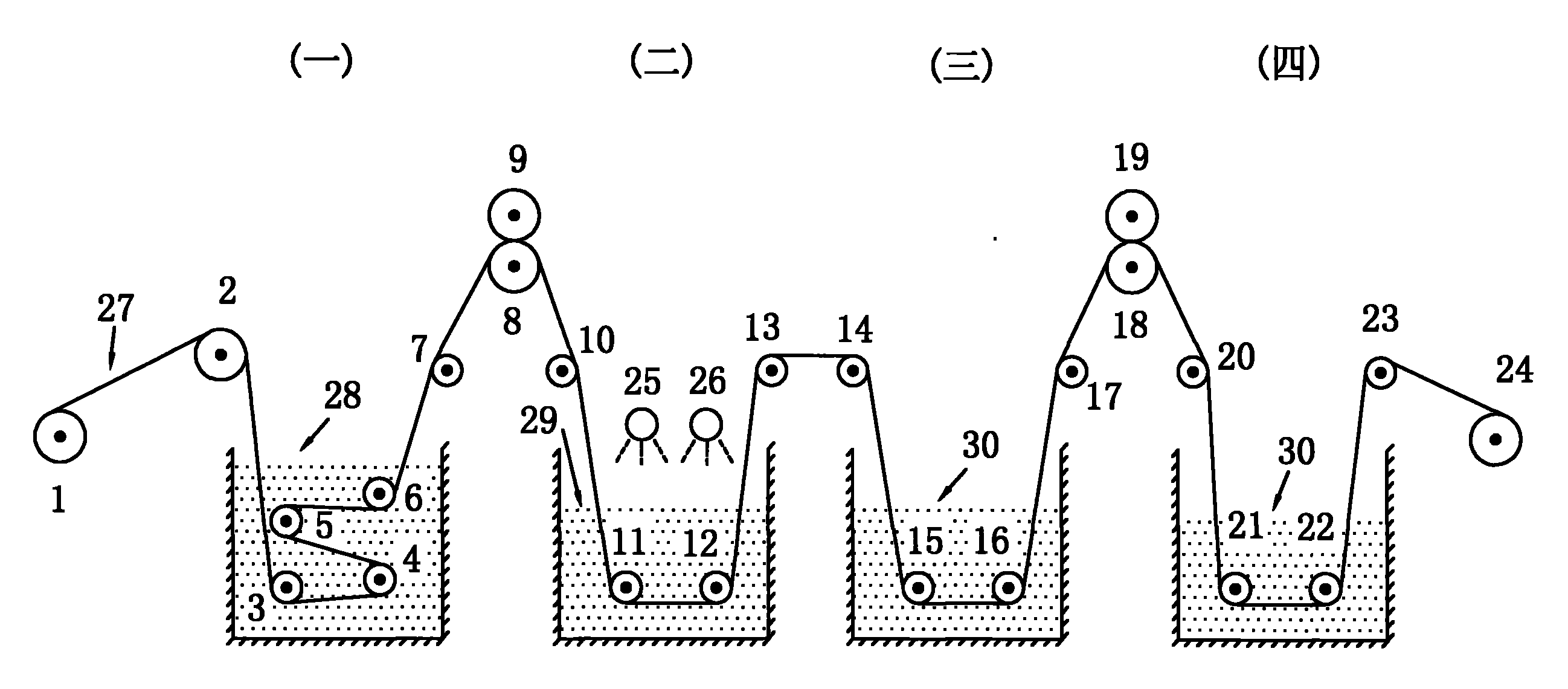

[0086] The method for preparing the non-woven fabric of the sulfonated diaphragm of the nickel-hydrogen battery and the sulfonated diaphragm of the nickel-hydrogen battery is as follows:

[0087] ① Preparation of sulfonated polypropylene-polyethylene composite fiber tow (sulfonated ES composite fiber tow)

[0088] Take 2 to 3 bundles of ES composite fiber tows with a fineness of 1.5dtex (about 100,000 single filaments), pass through the stainless steel guide roller 2 at the input end of the concentrated sulfuric acid bath, penetrate into the concentrated sulfuric acid bath, and pass through the concentrated sulfuric acid bath. The stainless steel guide rollers (3, 4, 5, 6) reciprocate and pass through several times, so that the ES composite fiber tow reciprocates in the concentrated sulfuric acid bath with a length of 30 meters, and then continues to pass through the stainless steel guide roller 7 at the output end of the concentrated sulfuric acid bath. 1. The first pair of t...

Embodiment 2

[0106] The method for preparing the non-woven fabric of the sulfonated diaphragm of the nickel-hydrogen battery and the sulfonated diaphragm of the nickel-hydrogen battery is as follows:

[0107] ① Preparation of sulfonated polypropylene-polyethylene composite fiber tow (sulfonated ES composite fiber tow)

[0108] Prepare sulfonated polypropylene fiber tow (sulfonated PP fiber tow) according to step ① method in Example 1, but the sulfonation process and dilute sulfuric acid cleaning process adopted are different: the concentration of the concentrated sulfuric acid is 96%, the temperature of the concentrated sulfuric acid The temperature is 120°C, and the holding time is 6min; the concentration of dilute sulfuric acid is 50%, and the temperature of dilute sulfuric acid is 90°C;

[0109] ② Preparation of sulfonated polypropylene fiber tow (sulfonated PP fiber tow)

[0110] According to step 1. method in embodiment 1, prepare sulfonated polypropylene fiber tow (sulfonated PP fib...

Embodiment 3

[0121] The method for preparing the non-woven fabric of the sulfonated diaphragm of the nickel-hydrogen battery and the sulfonated diaphragm of the nickel-hydrogen battery is as follows:

[0122] ① Preparation of sulfonated polypropylene-polyethylene composite fiber tow (sulfonated ES composite fiber tow)

[0123] Process according to the method of step 1 of Example 1, but the sulfonation process and the dilute sulfuric acid cleaning process are different: the concentration of concentrated sulfuric acid is 95%, the temperature of concentrated sulfuric acid is 116 ° C, and the holding time is 8 minutes; the concentration of dilute sulfuric acid is 30 %, and the temperature of dilute sulfuric acid is 80 ° C. ;

[0124] ② Preparation of sulfonated polypropylene fiber tow (sulfonated PP fiber tow)

[0125] Process according to step 1 of Example 1, but the sulfonation process and dilute sulfuric acid cleaning process used are different: the concentration of concentrated sulfuric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com