Special drill bit for tapered hole and application method of tapered hole

A drill bit and tapered hole technology, which is applied in anchoring technology and bar planting technology, and the field of anchor hole drill bits, can solve the problems of special drill bits without tapered holes, no technology, and no tapered holes, etc., to improve pre-tightening force and improve Strength, the effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

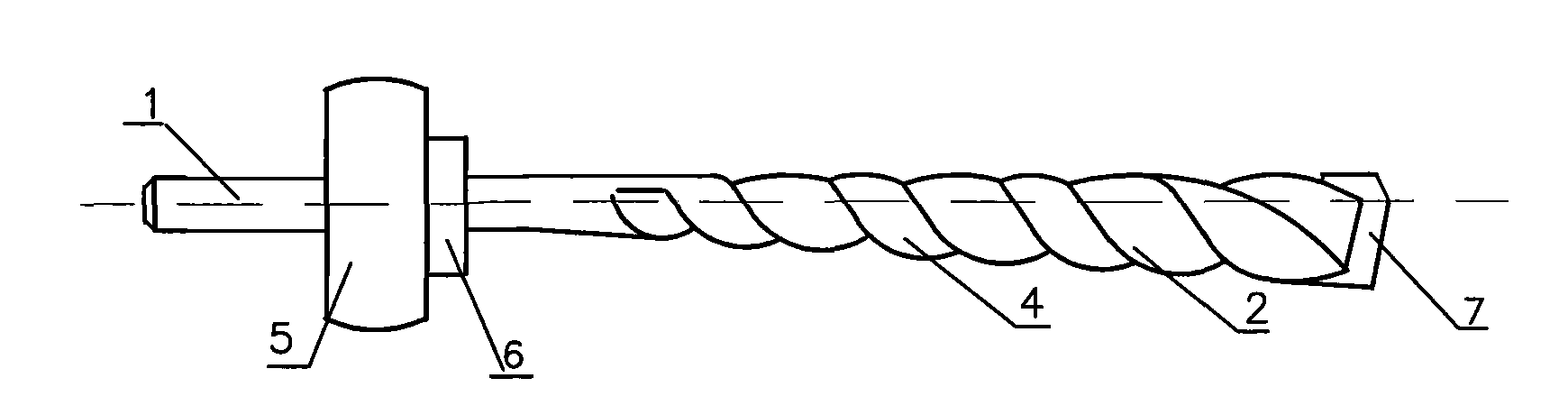

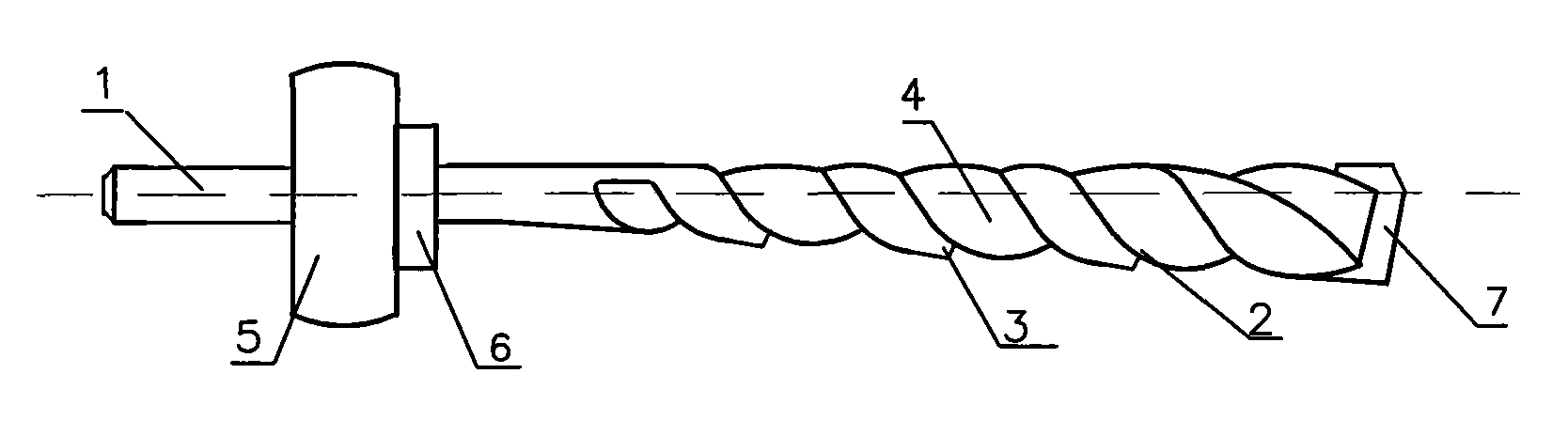

[0020] Embodiment 1: as figure 2 The special drill bit for tapered holes is composed of drill shank 1, blade face 2, positioning ring 6 and flexible limit ring 5. The drill handle 1 and blade face 2 are made as a whole; the positioning ring 6 and flexible limiter 5 are also made as As a whole, it is set on the drill shank 1; the angle between the outer edge of the blade surface 2 and the axis of the drill bit is an acute angle of 20°; The blade edge 4 has serrations 3 and is made of Yg11 alloy steel. Drill shank 1 diameter 20mm, drill bit total length 220mm, the right-angle side length 40mm of drill bit, the hypotenuse length 100mm of blade edge 4. The drill shank 1 is made of 9CrSi alloy structural steel, and the blade surface 2 is inlaid with a Yg11 hard alloy steel blade edge 4 . Locating ring 6 and flexible limit ring 5 are made of rubber.

Embodiment 2

[0021] Embodiment 2: as figure 2 The special drill bit for taper holes, the blade edge 4 has no serrations, the drill shank 1 is made of 40Cr steel, and the positioning ring 6 and the flexible limit ring 5 are made of rubber and plastic materials. All the other are with embodiment 1.

Embodiment 3

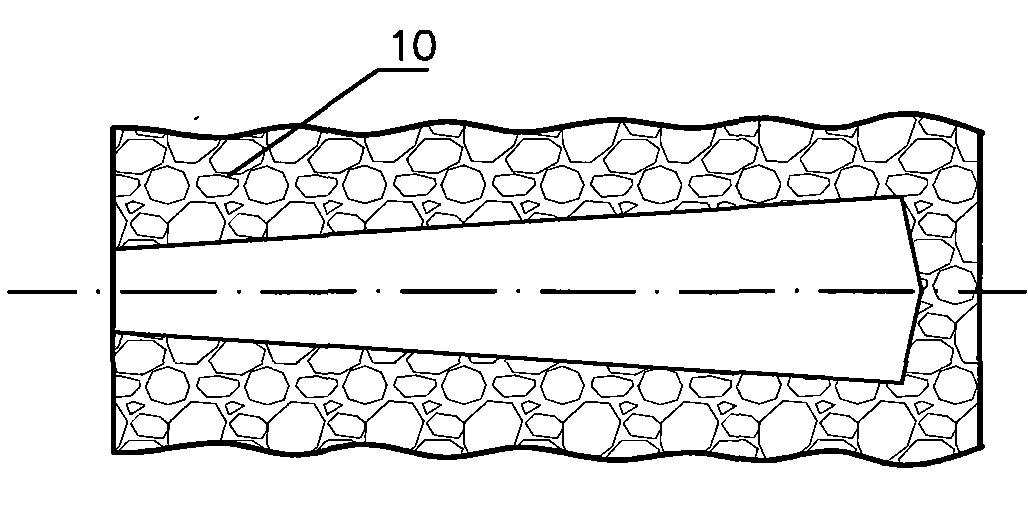

[0022] Embodiment 3: The application of tapered holes in anchoring technology. The base material 10 is concrete, and a tapered anchor hole is drilled with a special drill bit for tapered anchor holes on the concrete. The length of the tapered hole is 16 mm, and the diameter of the tapered hole inlet is 2 mm. Shape bottom diameter 4mm, such as image 3 ;Use the expansion-type special anchor bolt 7 with the nylon sleeve 8, and the appearance of the nylon sleeve 8 has ribs; press the expansion-type special anchor bolt 14 with the nylon sleeve 8 into the tapered anchor hole to make it expand The formed geometric shape coincides with the tapered anchor hole, and the surface of the anchor bolt 7 is closely combined with the tapered hole to play an anchoring role. There is a nut 13 on the top of the anchor bolt 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com