Piston-type direct-drive engine and design method for first taking force and then integrating

An integrated design and engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems that the engine cannot be reversed by external force, short service life of the engine, impossible strength of the gear shaft, etc., to achieve simple structure and long service life Long, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

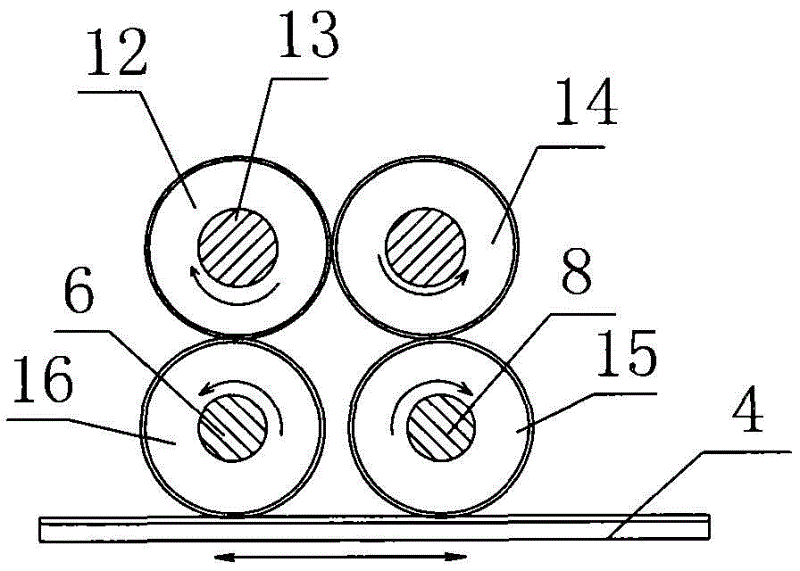

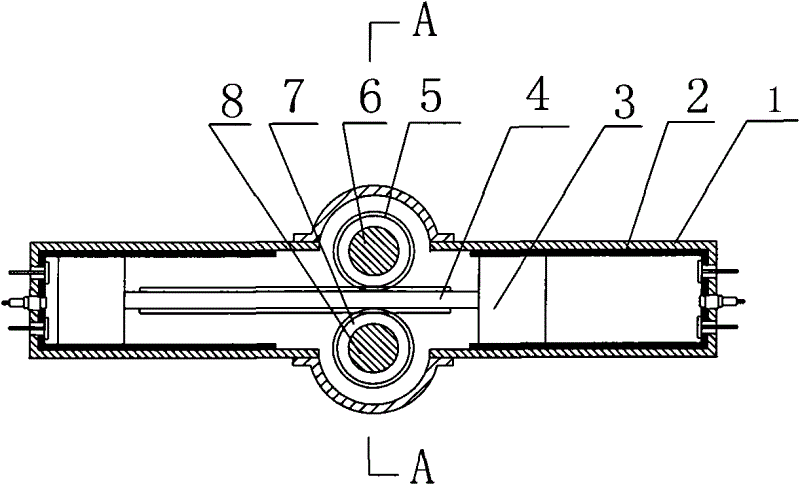

[0021] Embodiment 1: In the design of the present invention, the number of teeth on each side of the double-sided rack is greater than or equal to the number of the upper and lower transmission gears 5 and 7, and the double-sided rack 4 can drive the upper and lower transmission gears 5 and 7 forward and backward at the same time. Rotate two weeks.

[0022] If the sector gear 17 with arc length equivalent to the piston compression stroke is used to mesh with the starting gear 18 arranged on the upper transmission shaft 6 or the lower transmission shaft 8 for starting the engine, as figure 2 As shown, the number of teeth of the double-sided rack 4 can be greater than the gears of the upper transmission gear 5 and the lower transmission gear 7, that is, the double-sided rack 4 can drive the upper and lower transmission gears 5 and 7 to rotate for more than two weeks. The operating frequency of the piston, the output revolutions of the engine of the present invention can be at l...

Embodiment 2

[0026] In terms of calculating the compression ratio and ignition time, the double-sided rack direct drive structure of the present invention is also simpler and more convenient than the traditional crankshaft-connecting rod structure, because the stroke of the piston is the moving distance of the rack, and the moving distance of the rack By directly measuring the forward and reverse rotation of the transmission shaft, people can select and measure the best ignition time or compression ratio to obtain the greatest fuel saving effect and power output.

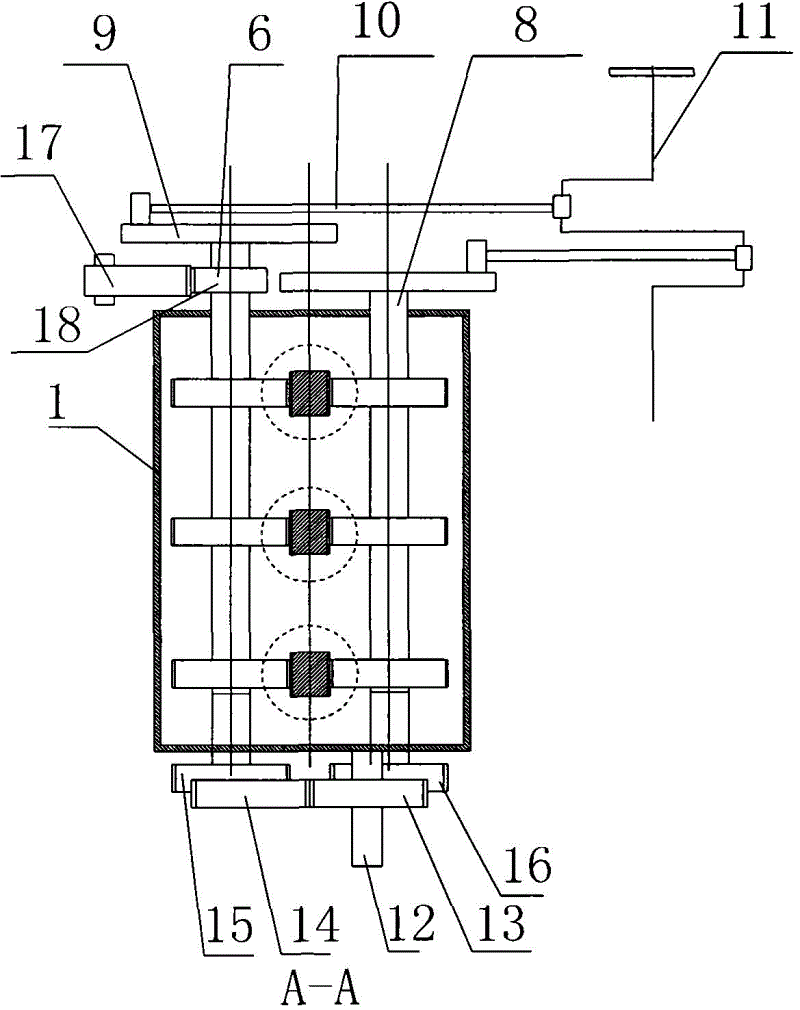

[0027] The engine cylinders are arranged in double rows opposite to each other in the engine casing, and the middle is connected by a gearbox. In this way, it is processed in three parts, and the process becomes quite simple, which provides convenience for assembly and maintenance.

[0028] The ignition system, intake and exhaust system, cooling system and lubricating system of the engine of the present invention are the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com