Energy-saving method and device for cylinder replacing work of internal combustion engine

An internal combustion engine and working technology, which is applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of not being fuel-efficient, and the effect of fuel-saving is not obvious, and achieve the effects of reducing cost expenditure, easy promotion and implementation, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

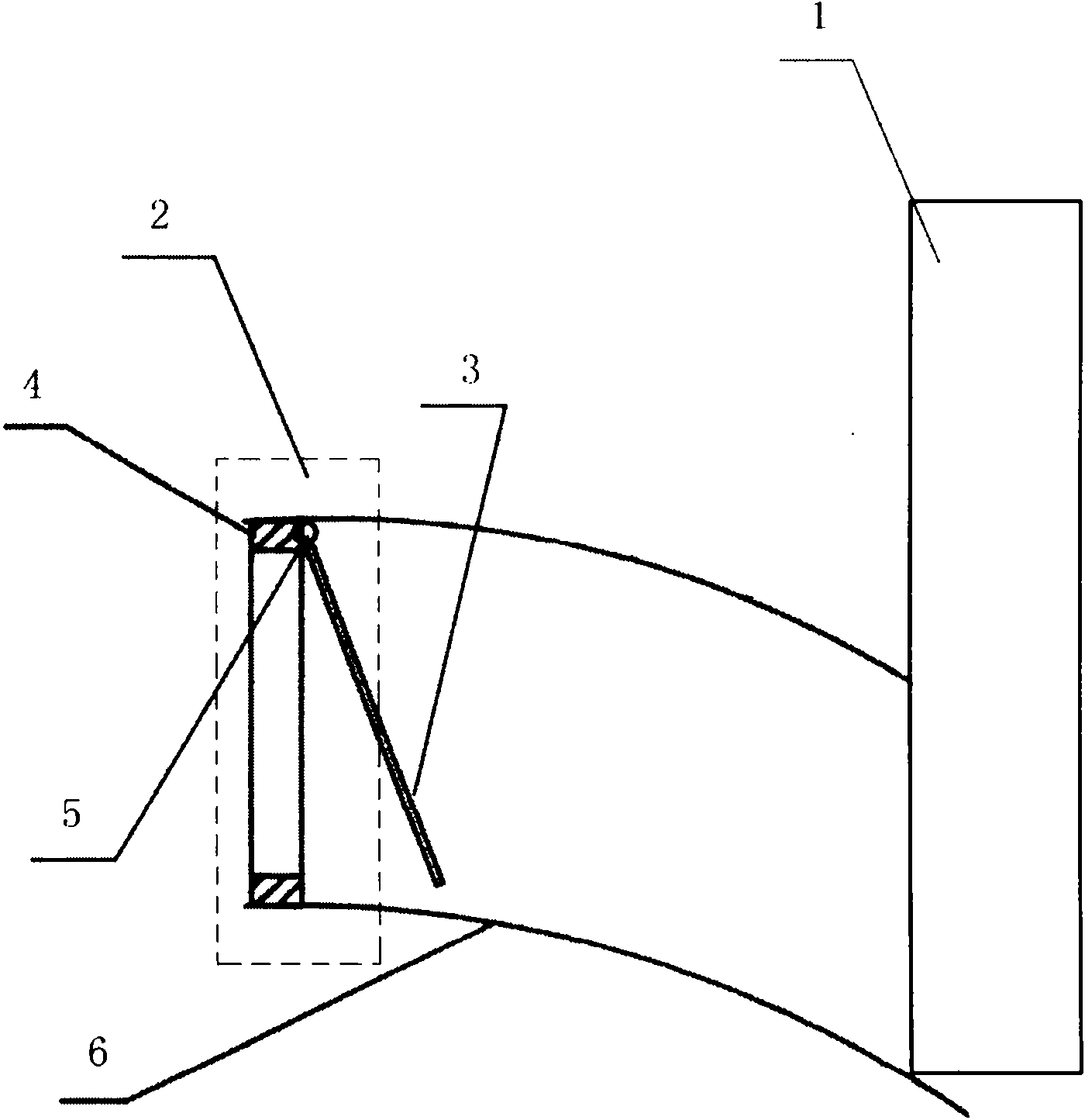

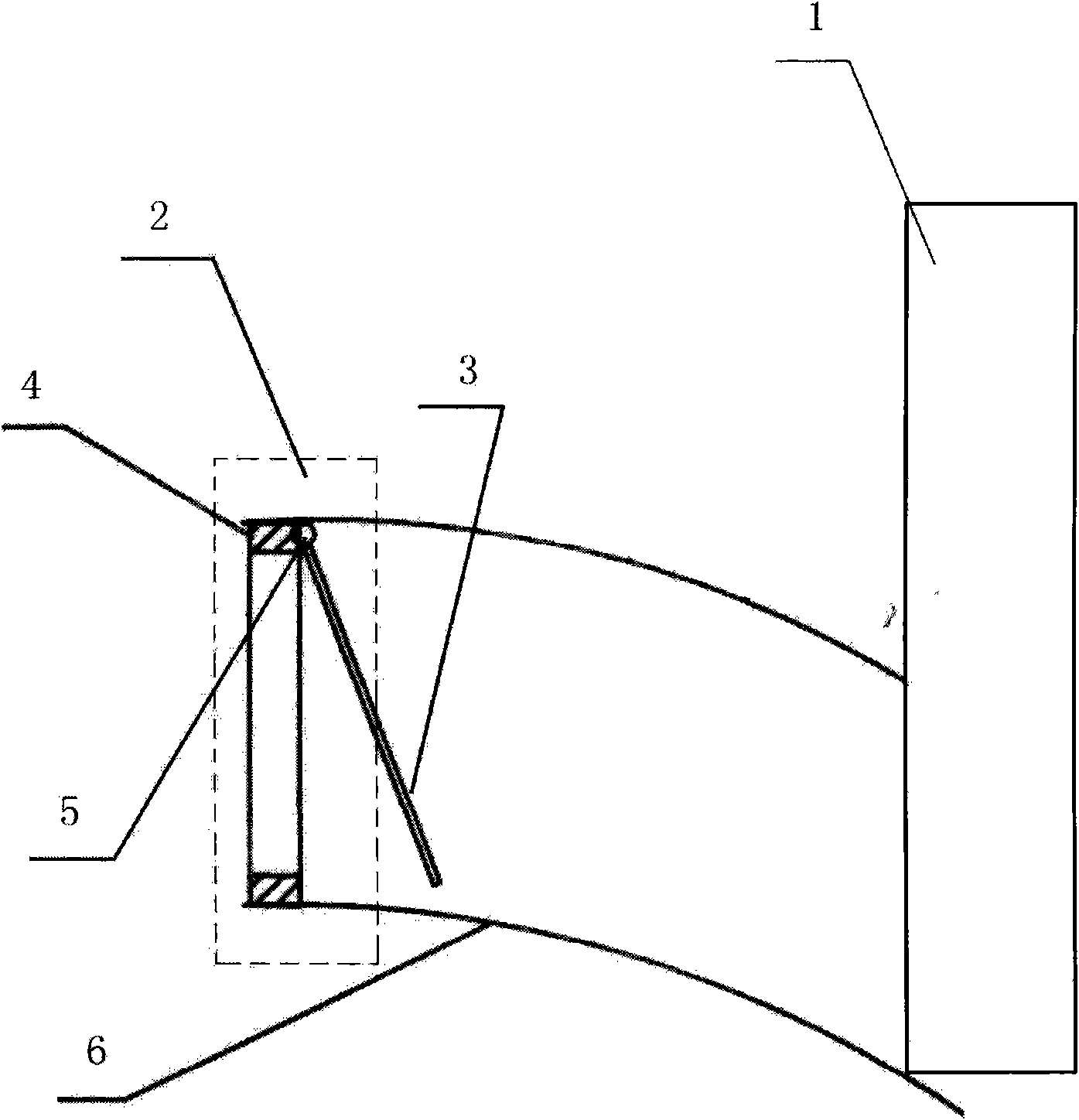

[0029]The principle of the present invention is to install a return air control valve controlled by an electronic control unit (ECU) on the intake side of 1 to n-1 cylinders of the internal combustion engine, which can be closed and opened as the internal combustion engine speed, load, etc. change or utilize the internal combustion engine The existing variable valve timing mechanism is appropriately improved, so that the intake valve is opened before the intake stroke starts, and the intake and return air that can be switched between closing after the intake stroke ends and the exhaust stroke starts are closed. Change the gas distribution phase mechanism, and inject or stop injecting fuel to the cylinder at the same time, so that the cylinder can change between the normal working state and the stopped working state, thereby reducing the air compression ratio of the compression stroke, reducing the energy consumption of the compression stroke and the power stroke, and In the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com