Constant-humidity air-cooling wine cabinet and microprocessor humidity control method thereof

A microprocessor, humidity control technology, applied in humidity control, non-electric variable control, control/regulation systems, etc., can solve the need for labels that are prone to moisture, mold, not suitable for wine storage in wine cabinets, and easy to use wine. volatilization and deterioration and other problems, to achieve the effect of improving the humidity control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

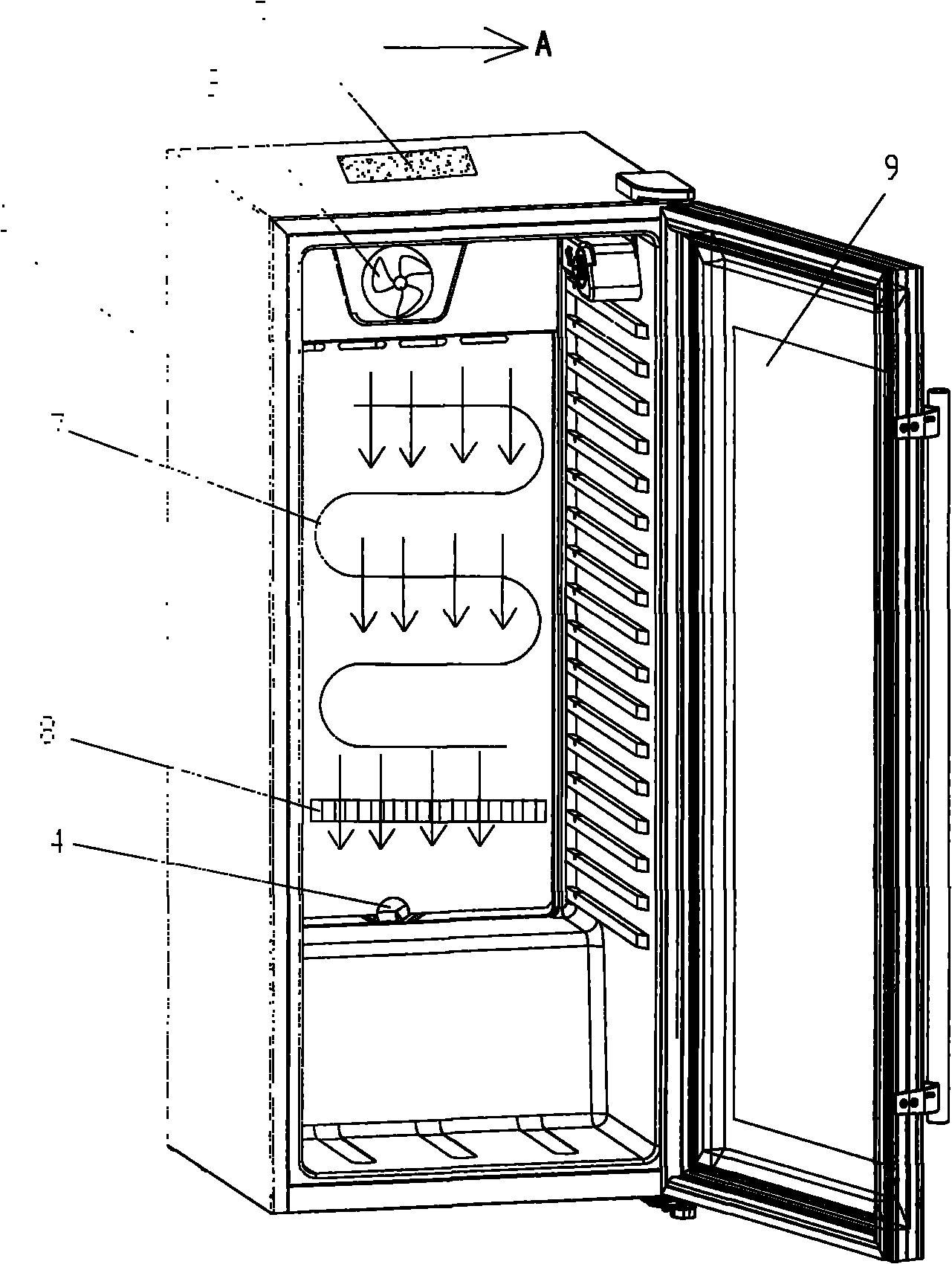

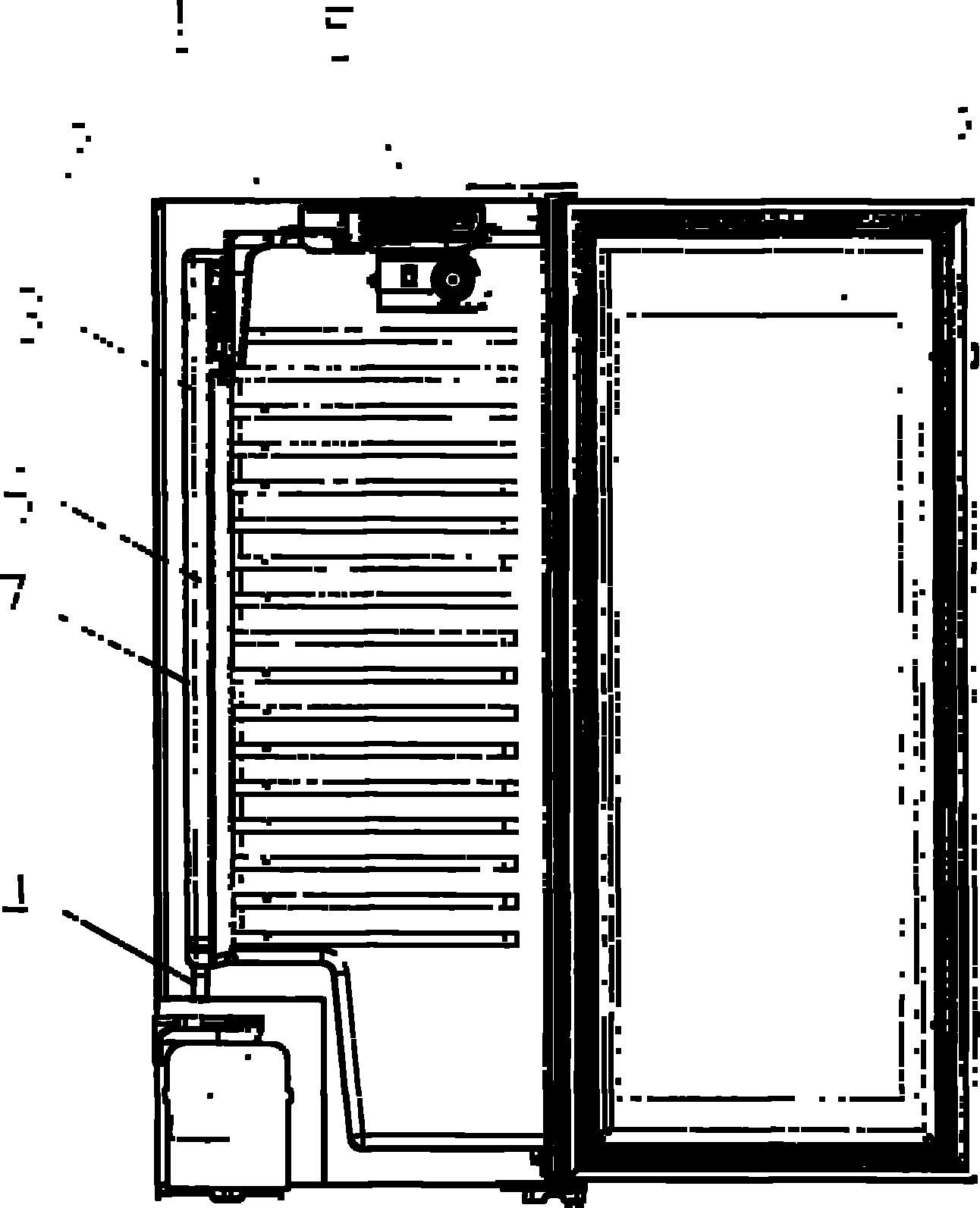

[0026] A constant humidity air-cooled wine cabinet, such as figure 2 , image 3 As shown, it includes a box body 1, a door body 9, a refrigeration unit, a humidifying fan 2, and a control unit 5. The refrigeration unit includes an evaporator 7 and a compressor. The box body 1 includes an evaporator cover 3 (evaporator cover 3). settings with figure 1 The setting of the air-cooled wine cooler in the prior art shown is the same, figure 2 It is the structural schematic diagram of the air-cooled wine cabinet of the present invention without the evaporator cover 3, the evaporator cover 3 is not shown), the evaporator cover 3 and the rear wall of the box 1 constitute an evaporator warehouse, and the evaporator 7 is arranged in In the evaporator compartment, an air inlet and an air outlet are arranged on the evaporator compartment; the humidifying fan 2 is arranged on the air inlet, and the air outlet faces the refrigerating area of the wine cabinet (the setting of the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com