High-power optical fiber side pumping coupler and manufacture method thereof

A side pumping and coupler technology, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of large coupling loss, poor reliability, and inconvenient production, so as to reduce insertion loss and improve stability and reliability. performance, the effect of a simple coupling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

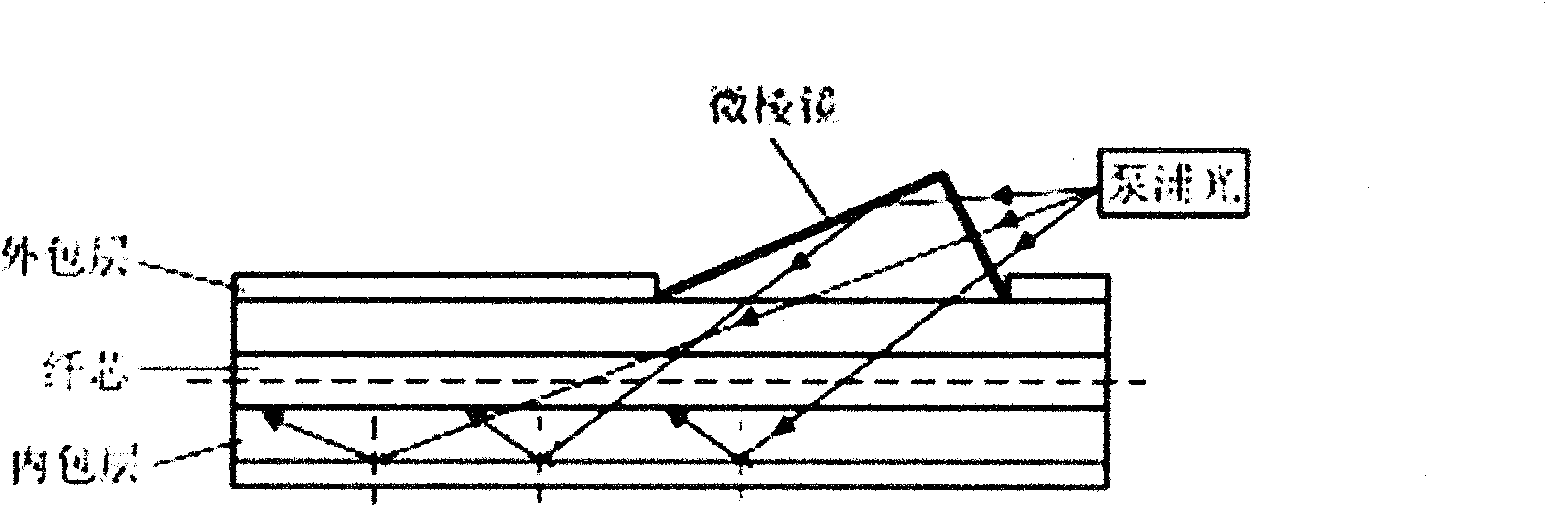

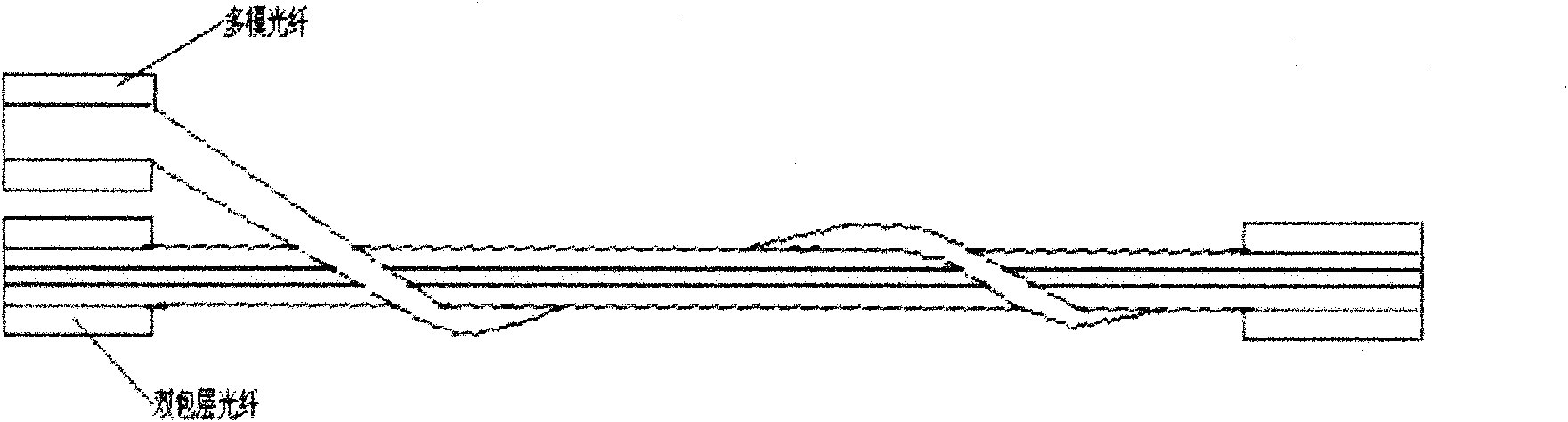

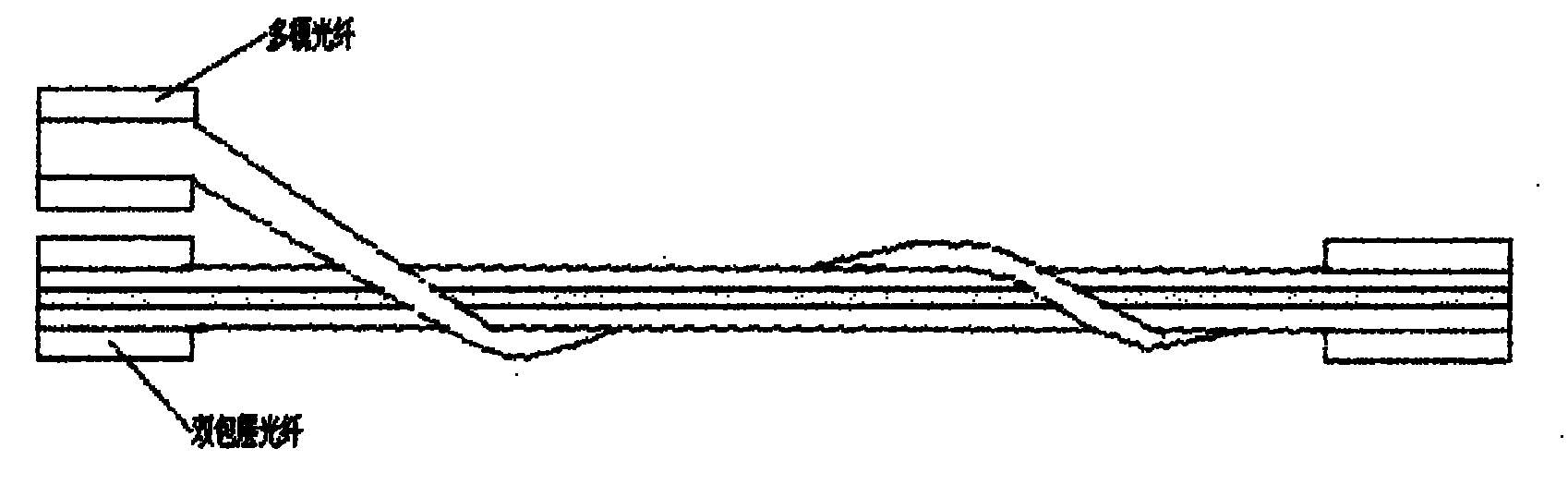

[0016] Choose a 105 / 125μm multimode fiber and a 5 / 130 / 250μm double-clad fiber, where the multimode fiber is used as the pump input fiber. First, the coating layer of one end of the multimode fiber (about 30mm long) is peeled off, and it is pulled down into a tapered shape at high temperature; The layer is stripped off, and then the tapered end of the prepared pump fiber is helically wound on the inner cladding side of the coupling part of the double-clad fiber (see figure 2 ); carry out hydrogen-oxygen flame heating and melting on the double-clad coupling part wrapped with the pumping fiber, inject pump light into the multimode fiber at the same time, and monitor the optical power output of the double-clad fiber, when the coupling efficiency of the pumping light When it is the highest (generally 93% to 95%), stop heating, pay attention to mastering the production pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com