Optical fiber microphone

A microphone and optical fiber technology, applied in the direction of sensors, electrical components, sensor components, etc., can solve the problems of no obvious increase in sensitivity and reduced volume, and achieve the effect of strong anti-electromagnetic interference and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

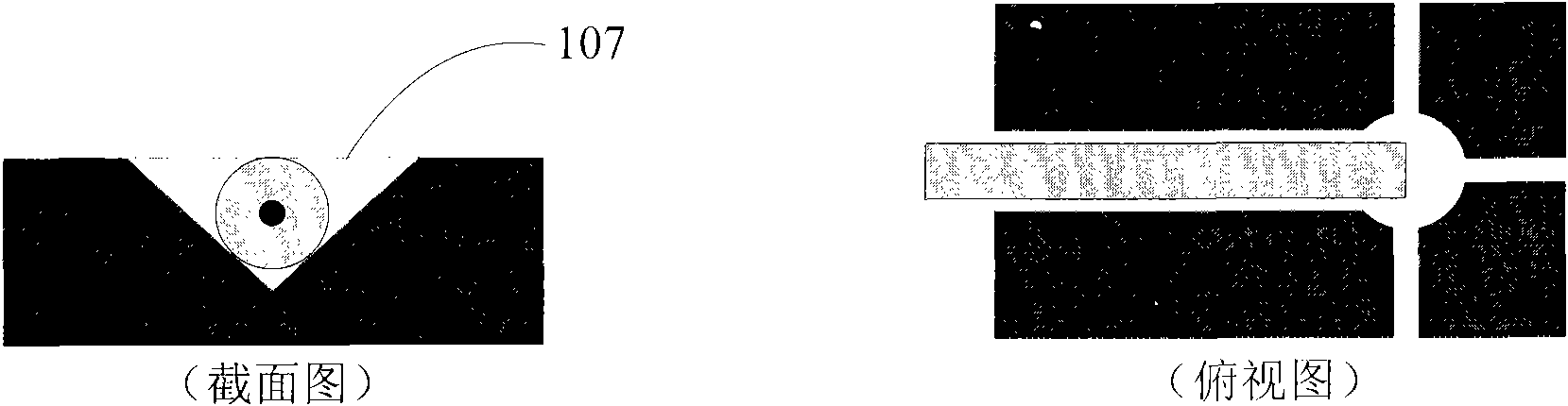

[0019] The invention provides a fiber optic microphone, such as Figure 4 As shown, the system includes an optical signal transmitting and receiving part 301 , a coupling unit 302 , a guiding fiber 303 and a fiber optic microphone probe 304 .

[0020] In this embodiment, the optical signal transmitting and receiving part 301 includes an optical signal generator 101 and a photoelectric conversion receiver 102 .

[0021] The optical signal generator 101 includes a light source part and a light source drive circuit part. The light source is an incoherent light source, which has a large emission angle. Generally, it is a light-emitting diode LED because of its simple structure and low price; it can also be replaced by a laser diode, a helium-neon laser, or a xenon arc lamp.

[0022] The part of the light source drive circuit is to ensure the stability of the emitted light intensity and low noise, because the stability and low noise of the light source are critical to the accurac...

Embodiment approach

[0034] The invention provides a fiber optic microphone, such as Figure 5 shown. The structure of the fiber optic microphone 2 is basically the same as that of the fiber optic microphone 1 in the first embodiment. The difference lies in: the material and thickness of the vibrating membrane 212 of the fiber optic microphone 2 are different, the vibrating membrane of the fiber optic microphone 2 is made of silicon dioxide, and its thickness is 2um. The Young's modulus of silicon dioxide is smaller than that of silicon nitride, so although the thickness increases, the Young's modulus is small, and the sensitivity can still be guaranteed. In addition, the number of vents 208 and sound inlets 206 of the fiber optic microphone can be changed, thereby changing the sensitivity of the microphone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com