Method for processing machine elements and device thereof

A technology of mechanical parts and processing methods, applied in the field of gear processing, clamping units and processing equipment, can solve problems affecting the processing accuracy and quality of parts, improve processing accuracy, overcome alignment and positioning errors and the accumulation of process errors , to avoid the effect of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

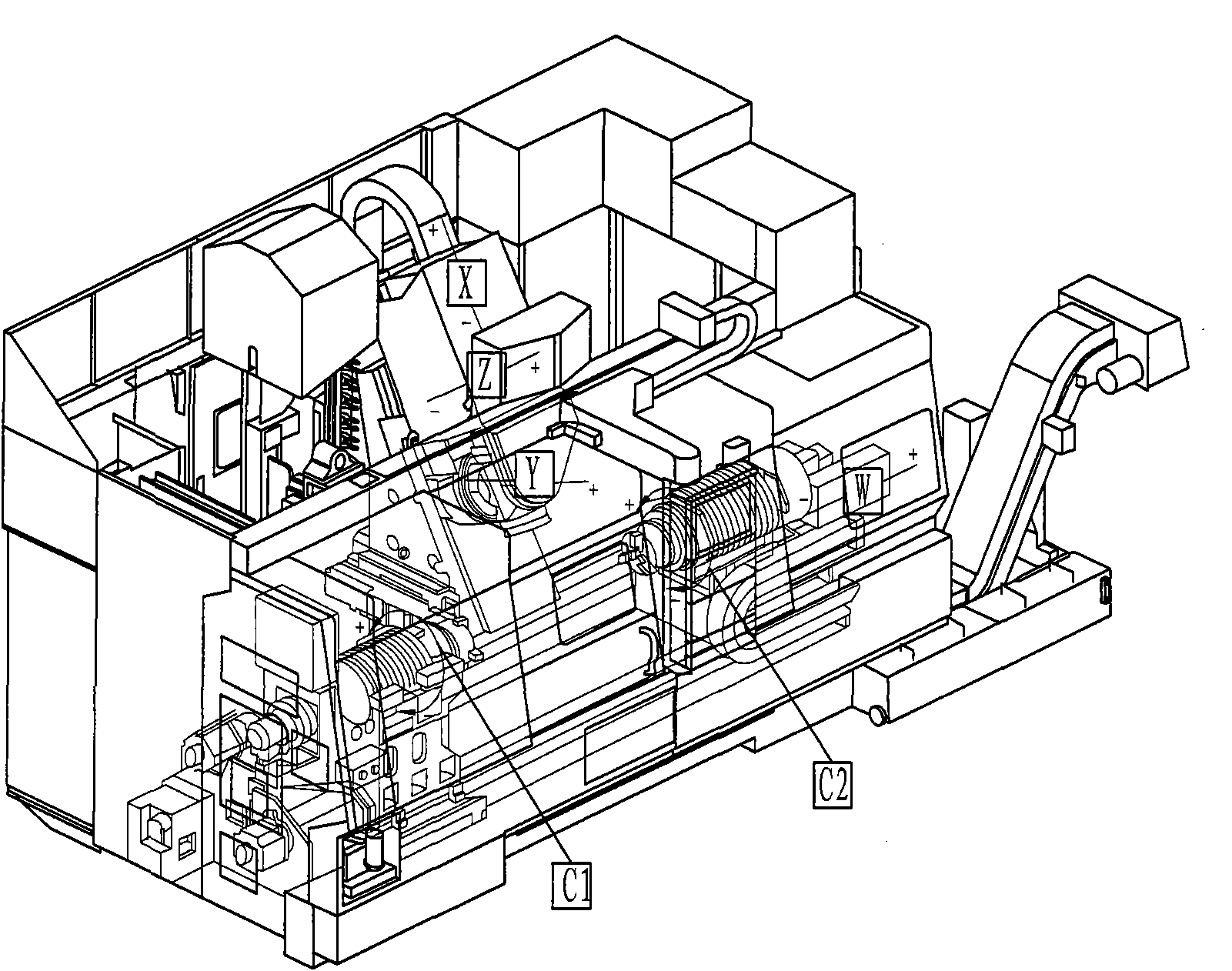

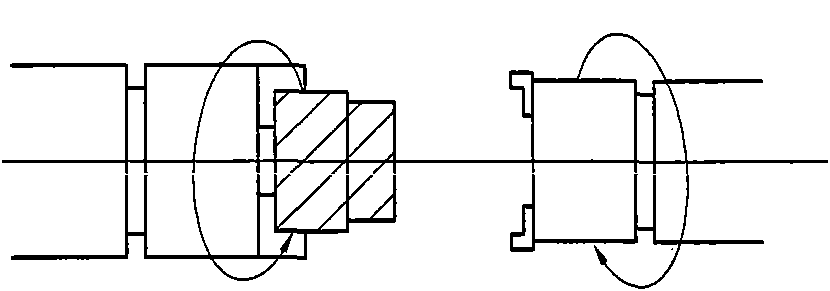

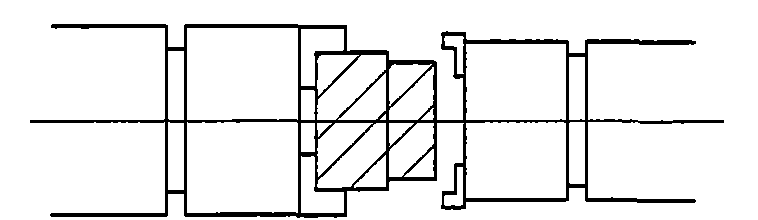

[0056] Embodiment 1: process high precision gear (as attached Figure 6 , 7 shown):

[0057]

Embodiment 2

[0058] Embodiment 2: hypoid gear (as attached Figure 8 , 9 shown)

[0059]

[0060] From the above two examples, it can be seen that all the content from quenching and tempering to gear cutting is completed in one clamping (including the handover of C-axis and C2-axis workpieces), such as turning, milling, drilling, reaming, rolling, etc. process. The entire machining process basically avoids the influence of human factors. All the dimensional accuracy and shape and position accuracy of the gear are completely determined by the accuracy of the machine tool and the tool itself. Therefore, product precision is guaranteed while improving production efficiency.

[0061] Since the spindle speed of the turning and milling center is as high as 10,000rpm, it can completely replace grinding in some occasions. Therefore, all the processes of gear datum and tooth shape correction can also be completed in one clamping on the turning-milling machining center, thus ensuring the fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com