Patents

Literature

33 results about "Procedure error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

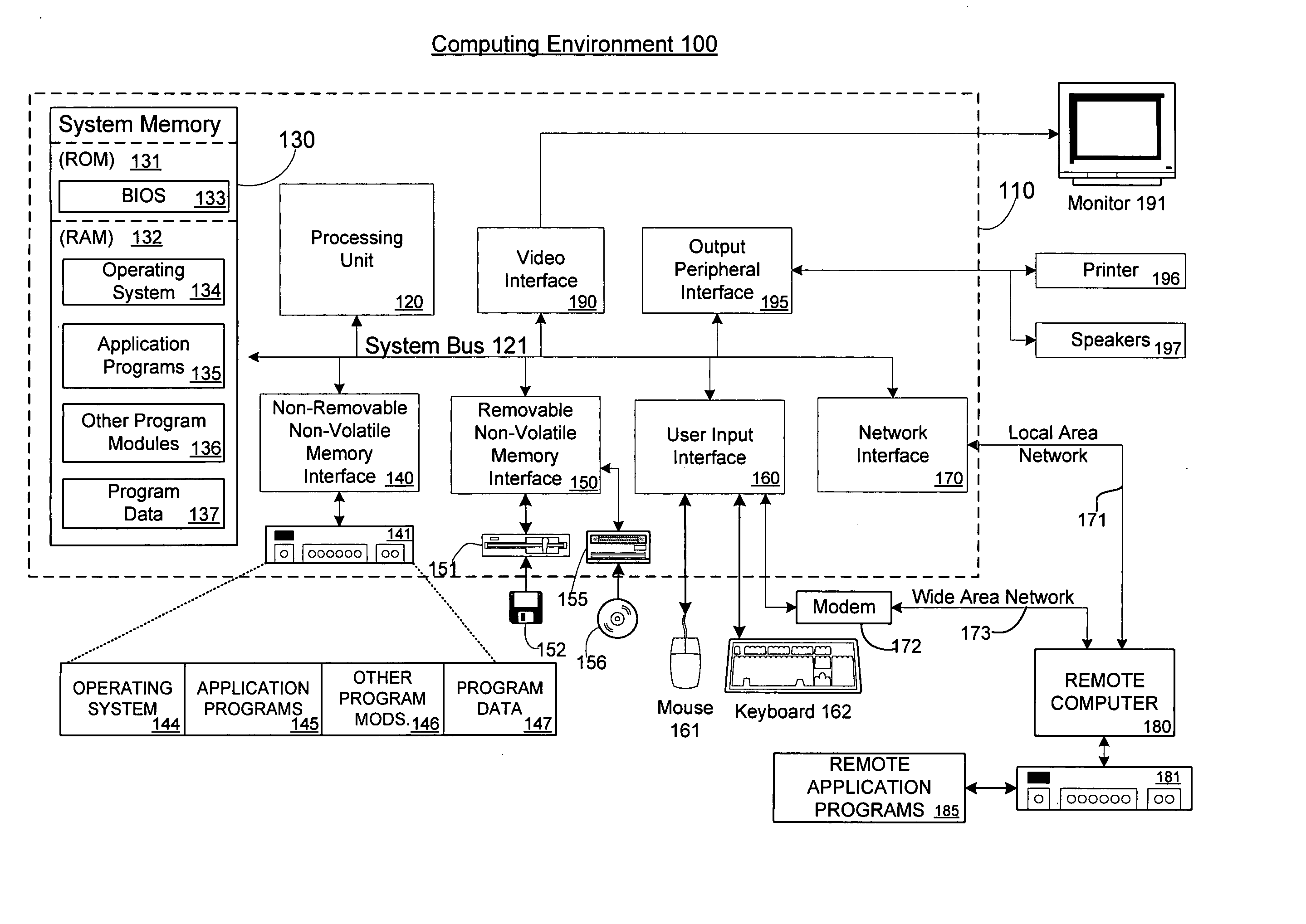

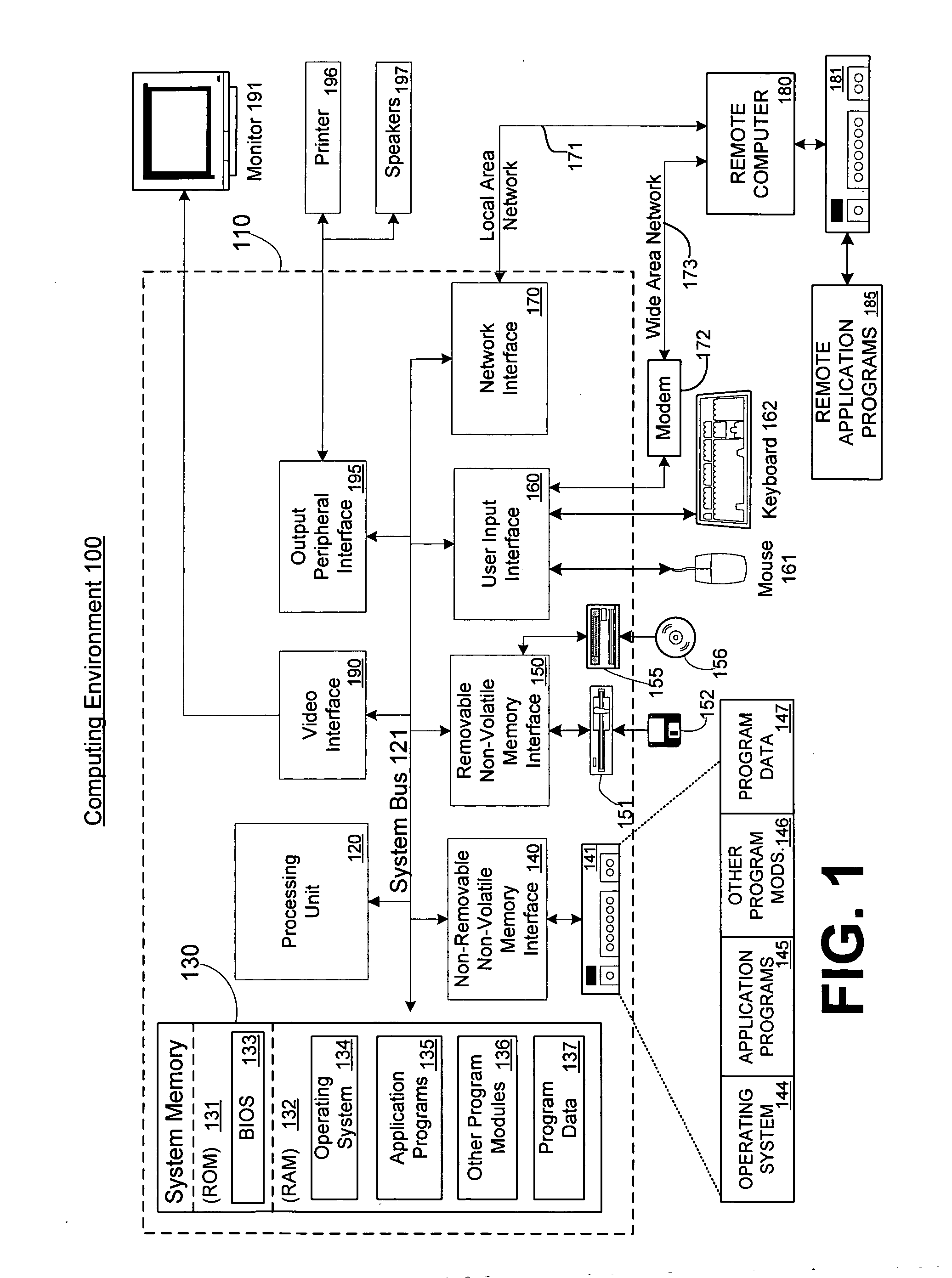

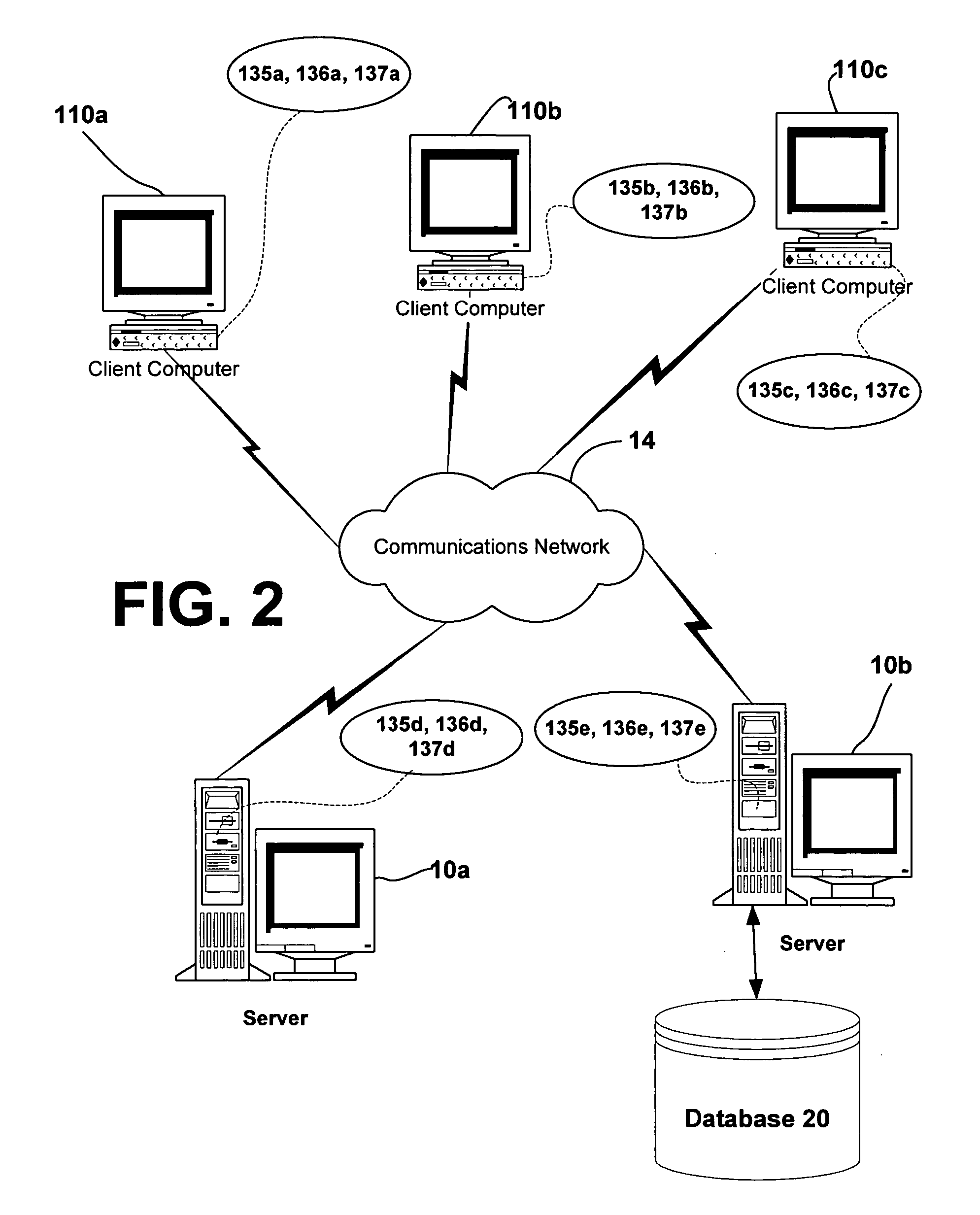

Static analysis based error reduction for software applications

InactiveUS20050015752A1Easy to liftSimple technologyError detection/correctionSpecific program execution arrangementsError reductionMaintainability

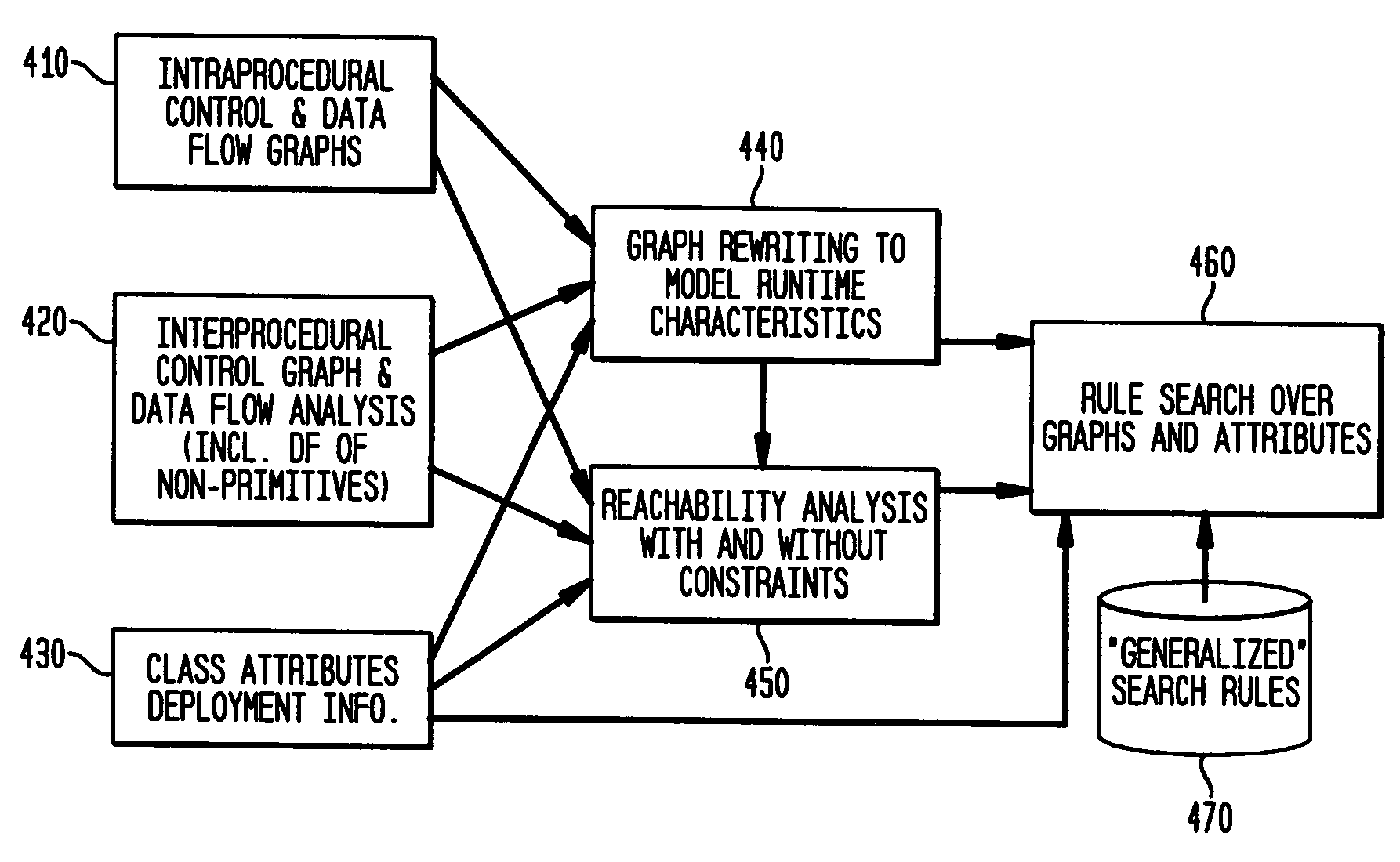

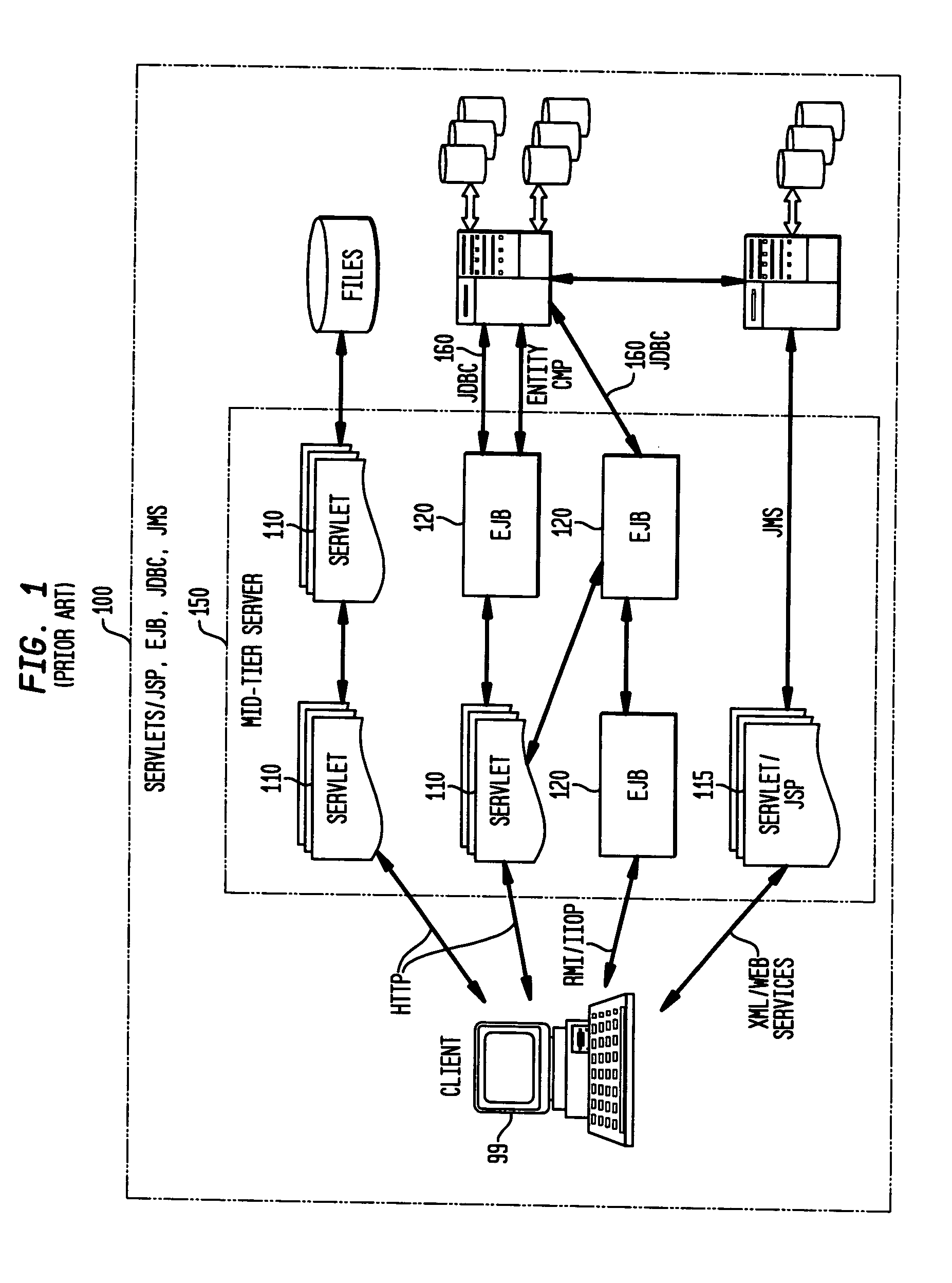

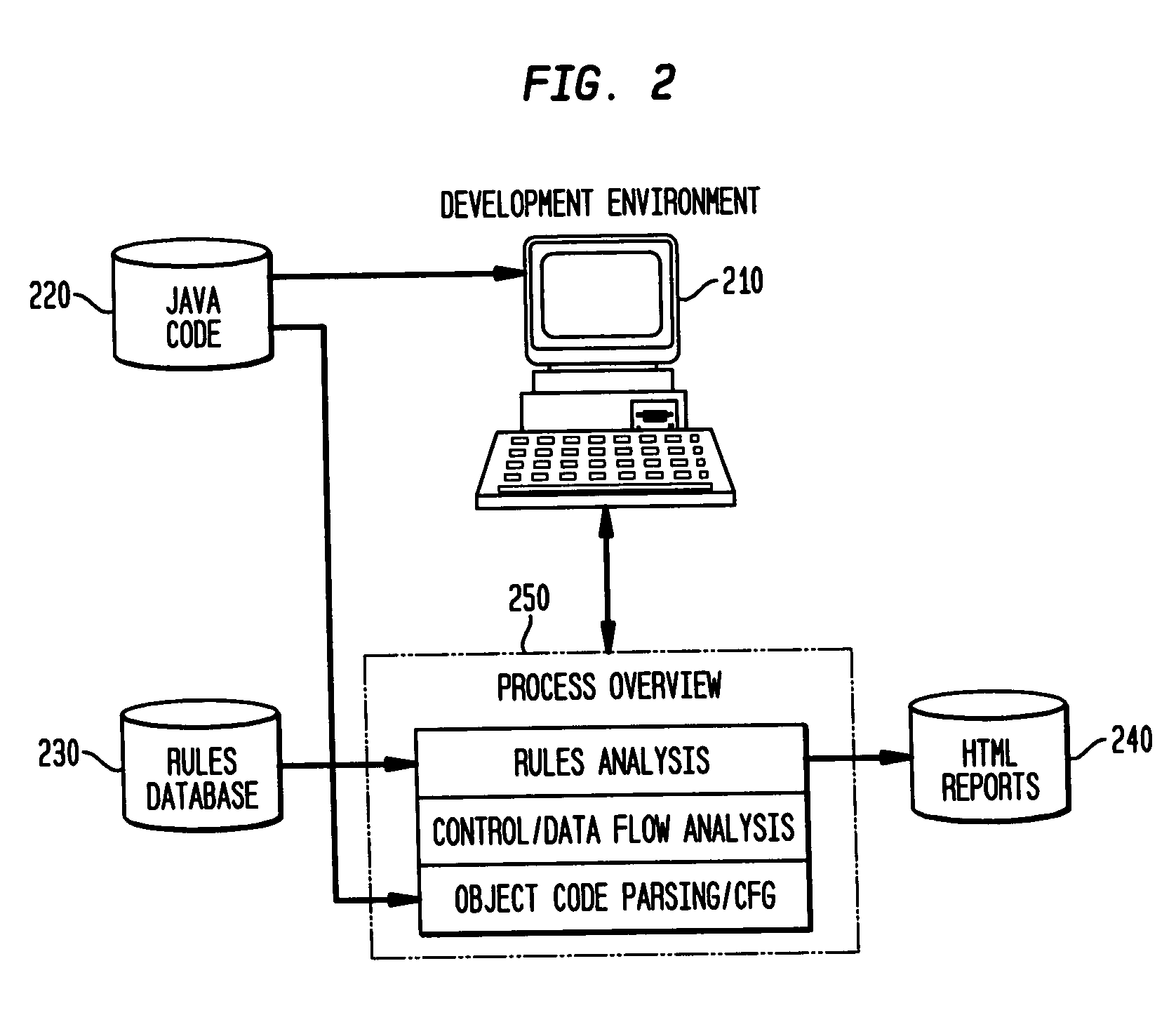

A system and method for providing “static analysis” of programs to aid in improving runtime performance, stability, security and privacy characteristics of deployed application code. The method includes performing a set of analyses that sifts through the program code and identifies programming security and / or privacy model coding errors. In particular the invention focuses on identifying coding errors that cause loss of correctness, performance degradation, security, privacy and maintainability vulnerabilities. A deep analysis of the program is performed using detailed control and data flow analyses. These deeper analyses provide a much better perspective of the overall application behavior. This deep analysis is in contrast to shallow analyses in current industry tools, which inspect or model a single or a few classes at a time.

Owner:IBM CORP

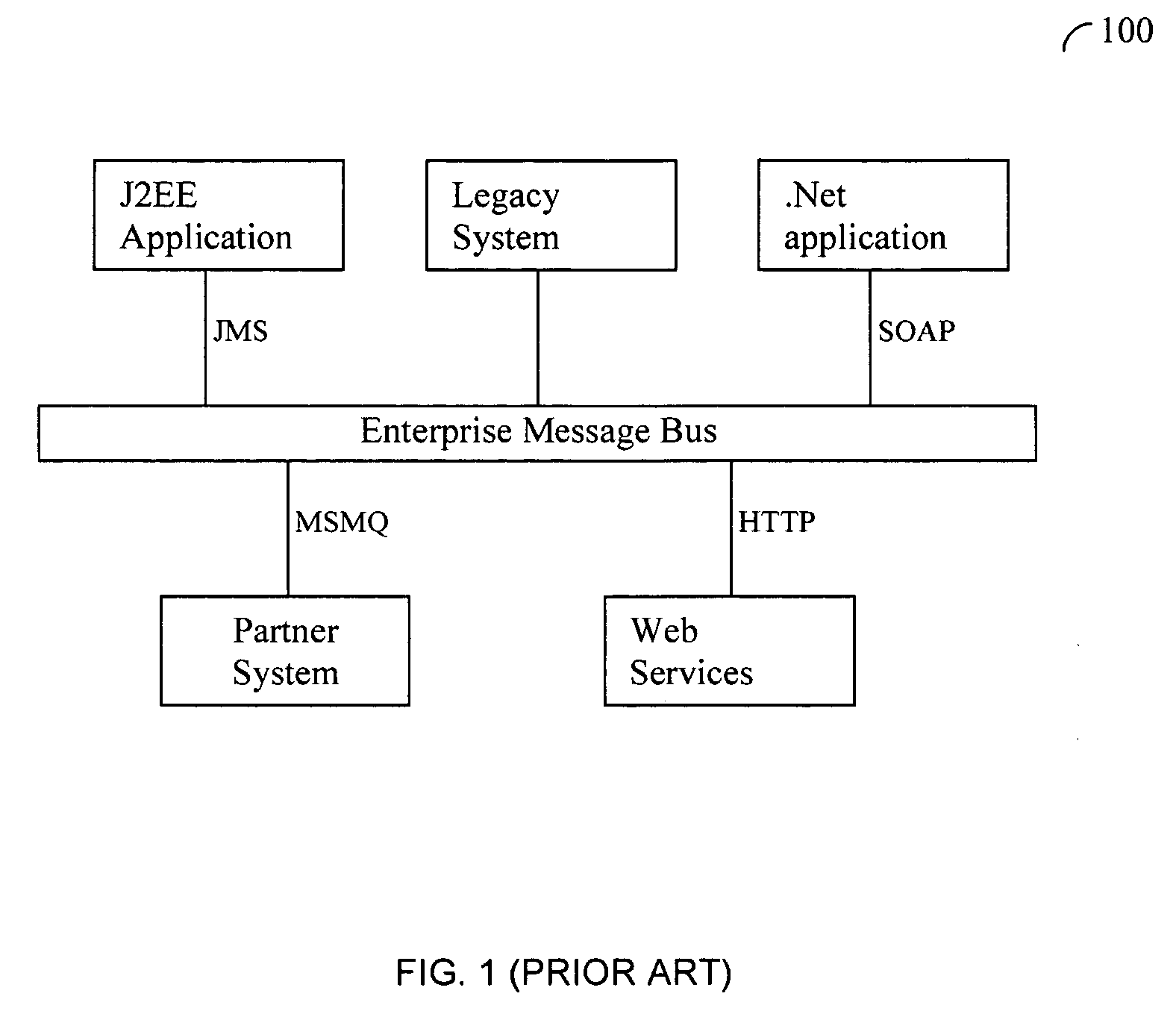

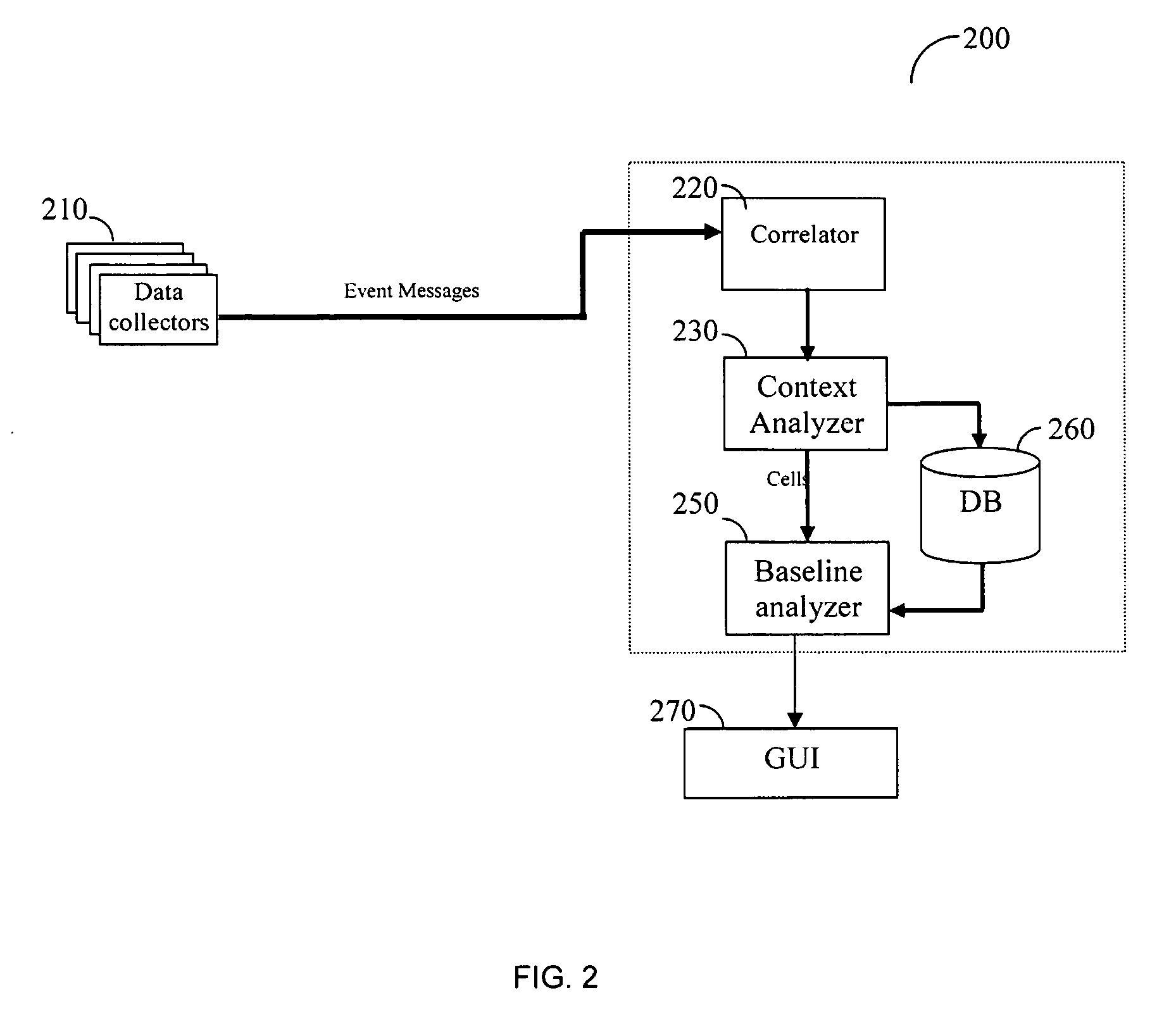

Method and apparatus for automatically discovering of application errors as a predictive metric for the functional health of enterprise applications

InactiveUS20060026467A1Fast root causePromote recoveryReliability/availability analysisFunctional healthProcedure error

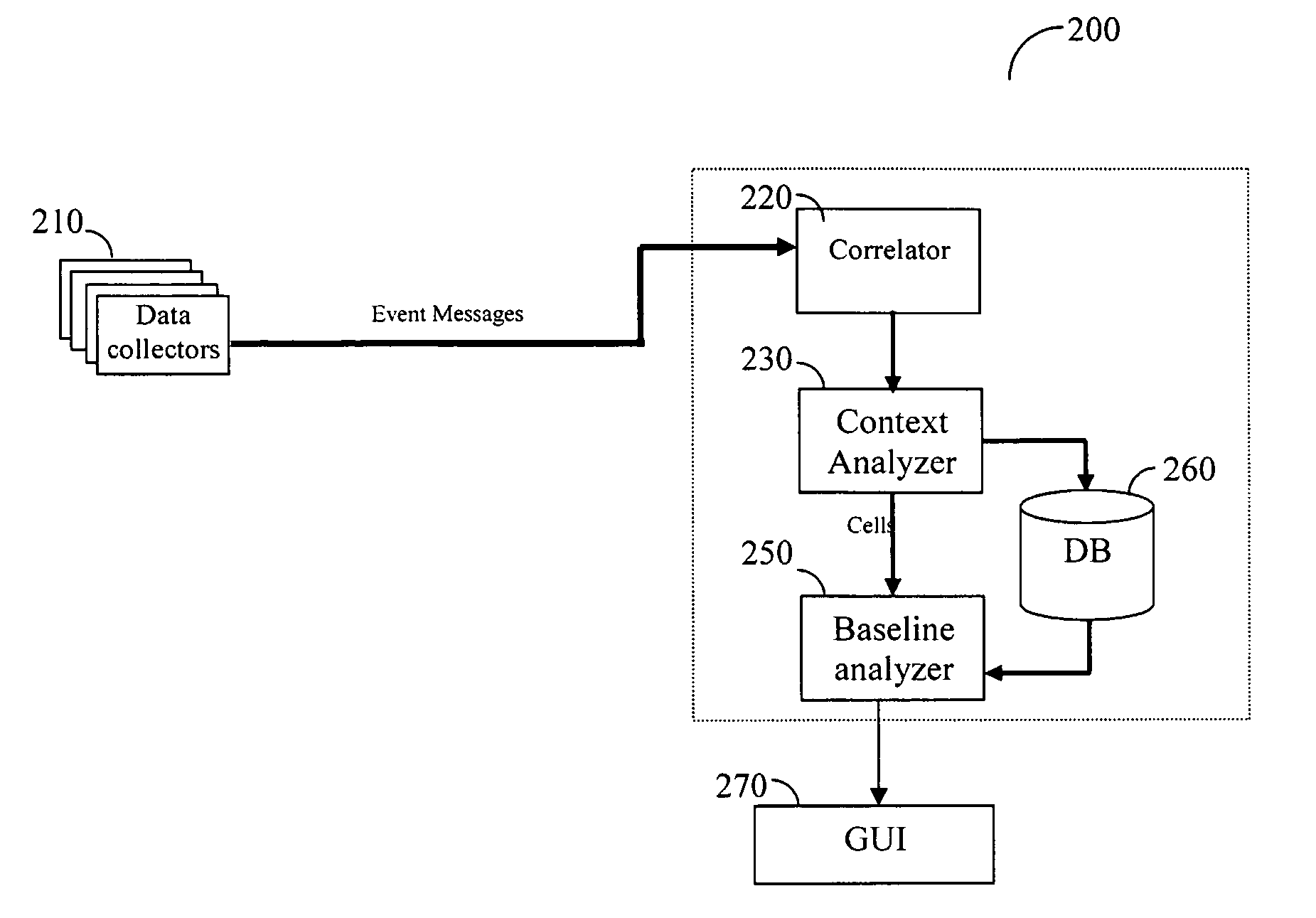

A method and apparatus that uses application errors as a predictive metric for overall measuring of applications functional health are disclosed. The automated system intercepts messages exchanged between inter-services of enterprise applications, analyzes the context of those messages, and automatically derives application errors embedded in the message. Thereafter, it is capable of showing deviations from expected behavior for the purposes of predicting failures of the monitored application. Furthermore, the invention displays the user's real-time actionable data generated using the application errors.

Owner:CERTAGON

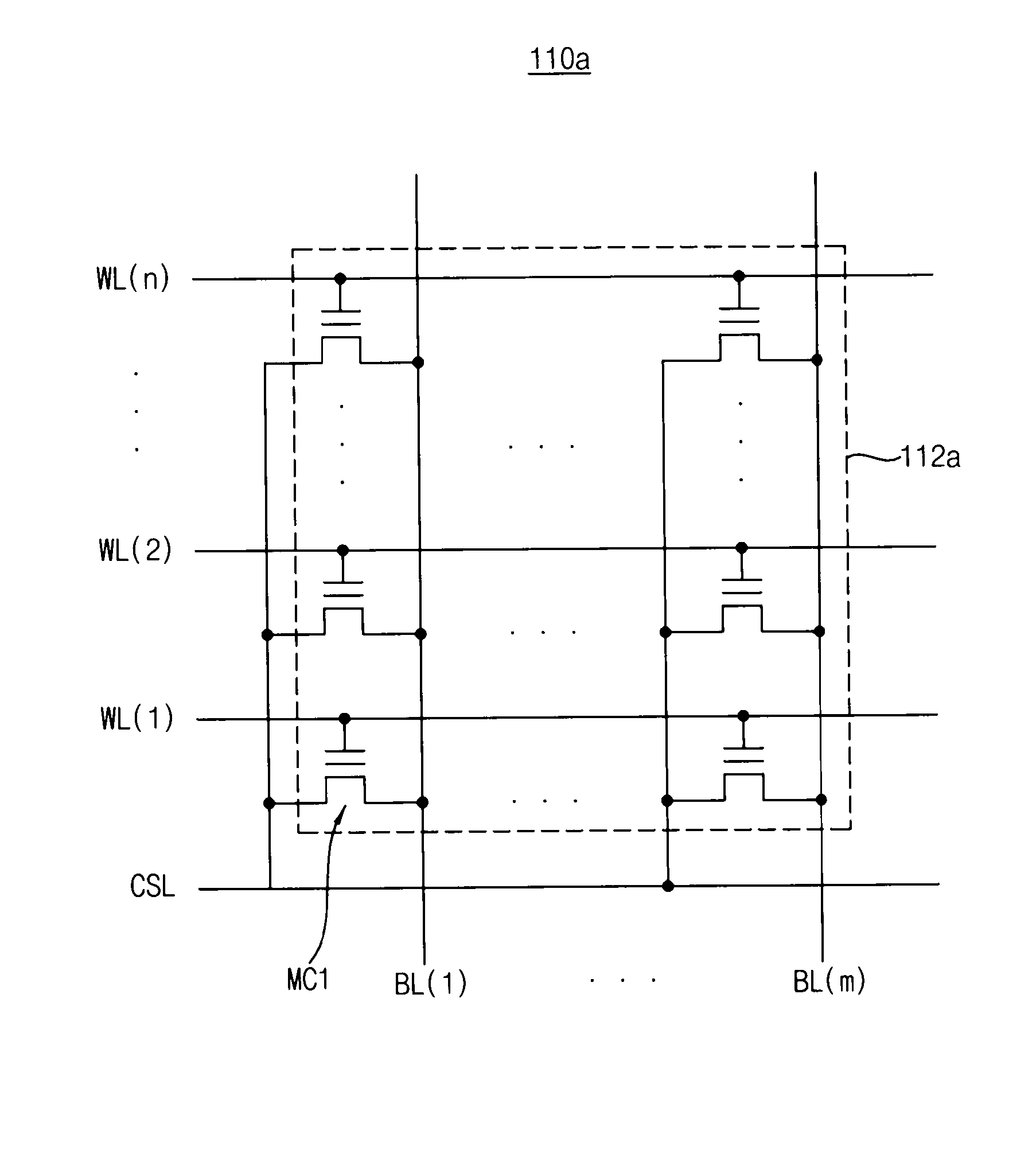

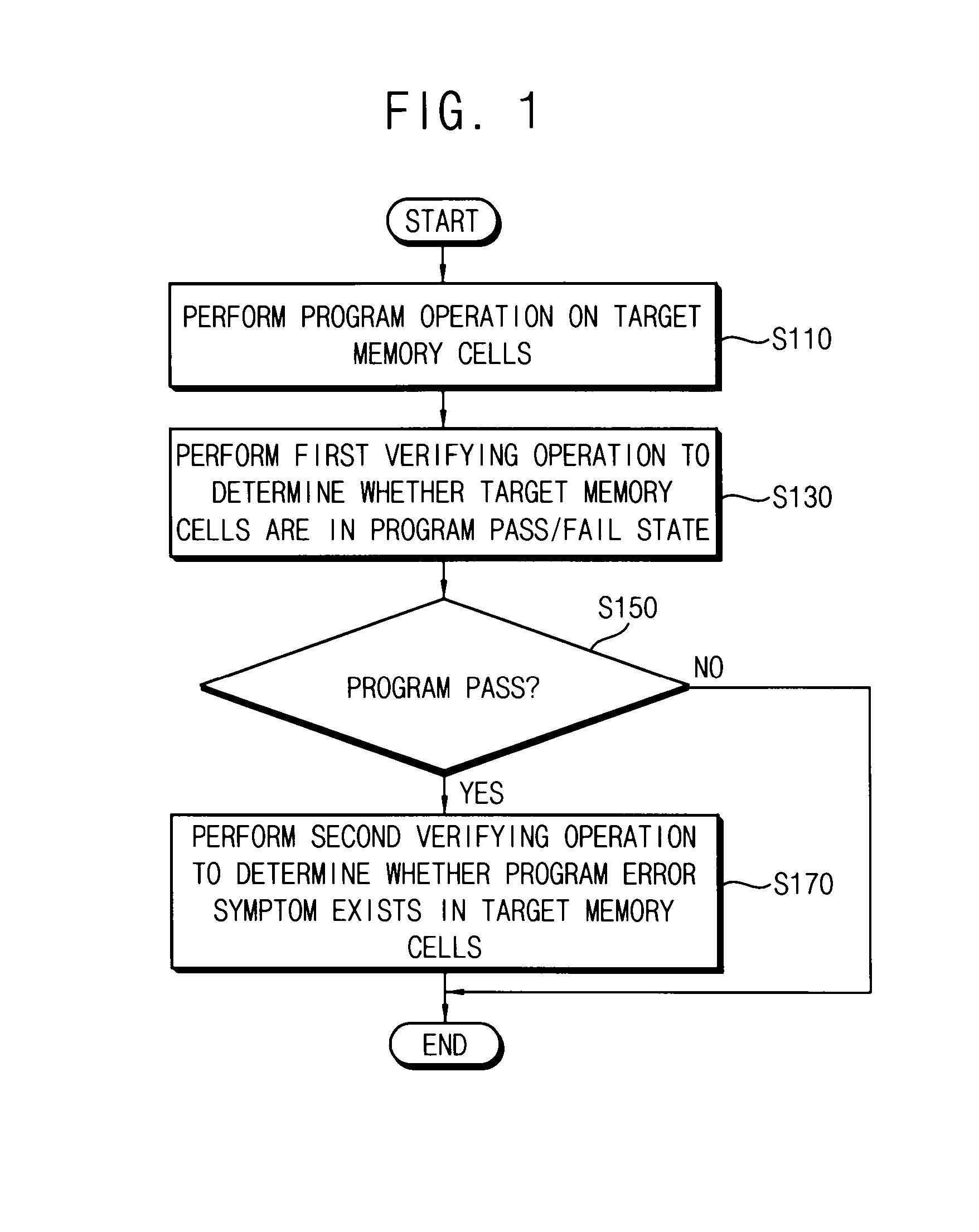

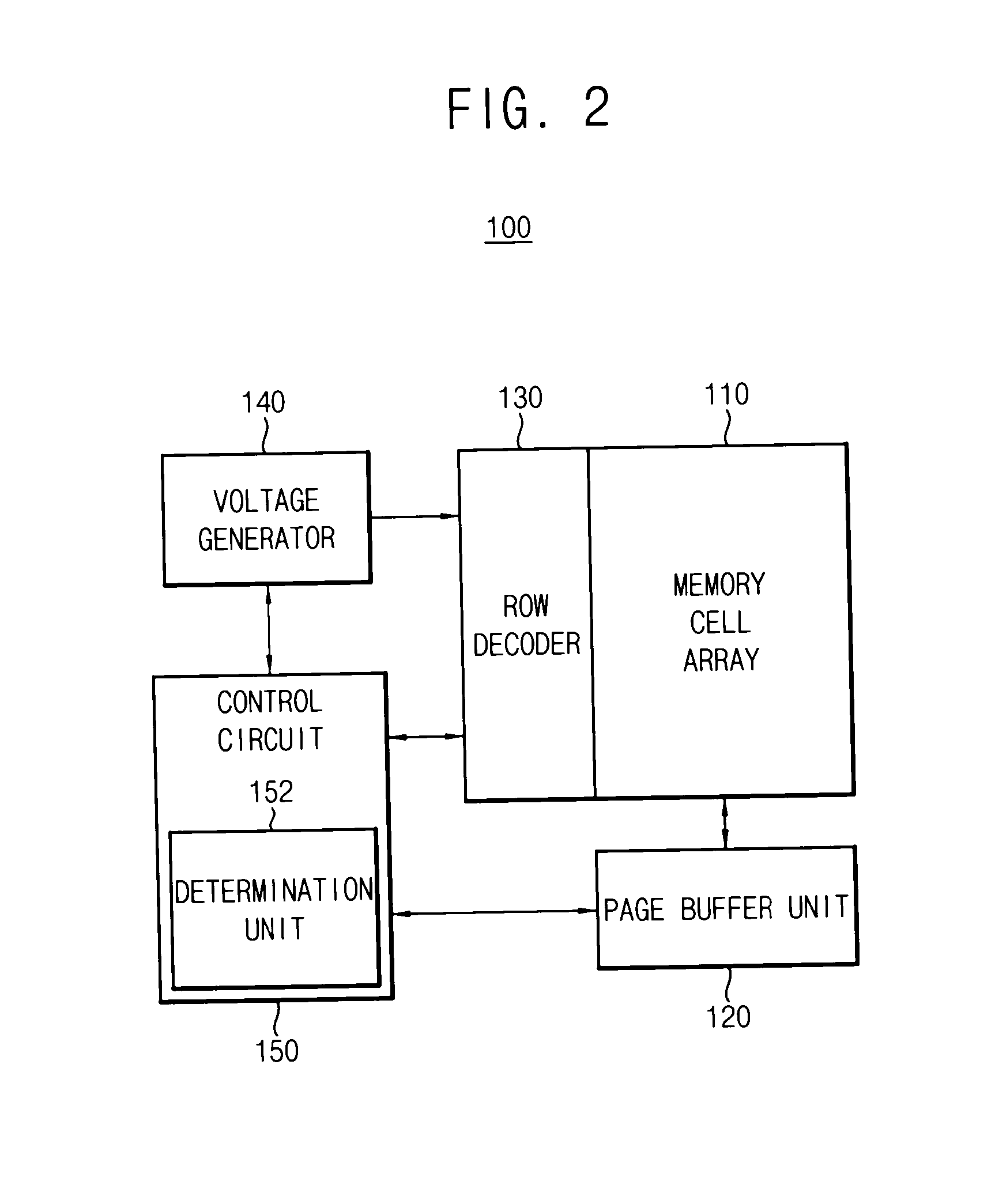

Method of storing data in nonvolatile memory device and method of testing nonvolatile memory device

ActiveUS20140198581A1Improve reliabilityAvoid future data lossStatic indicating devicesRead-only memoriesOperating systemProcedure error

Owner:SAMSUNG ELECTRONICS CO LTD

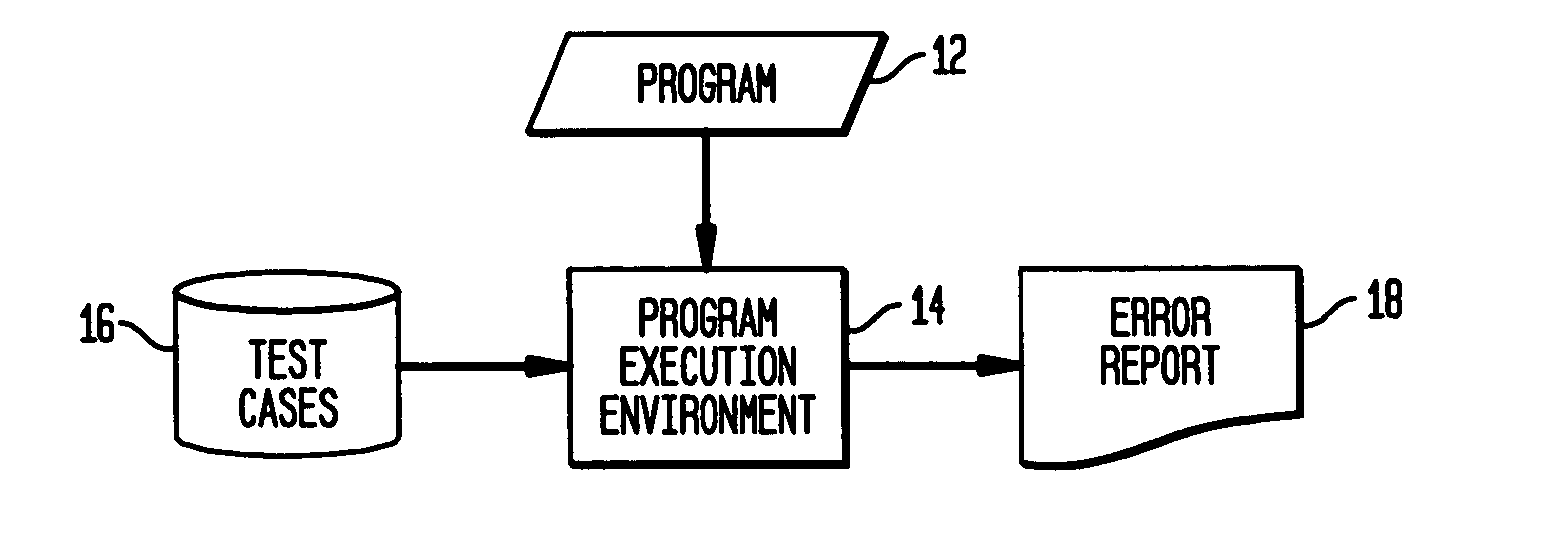

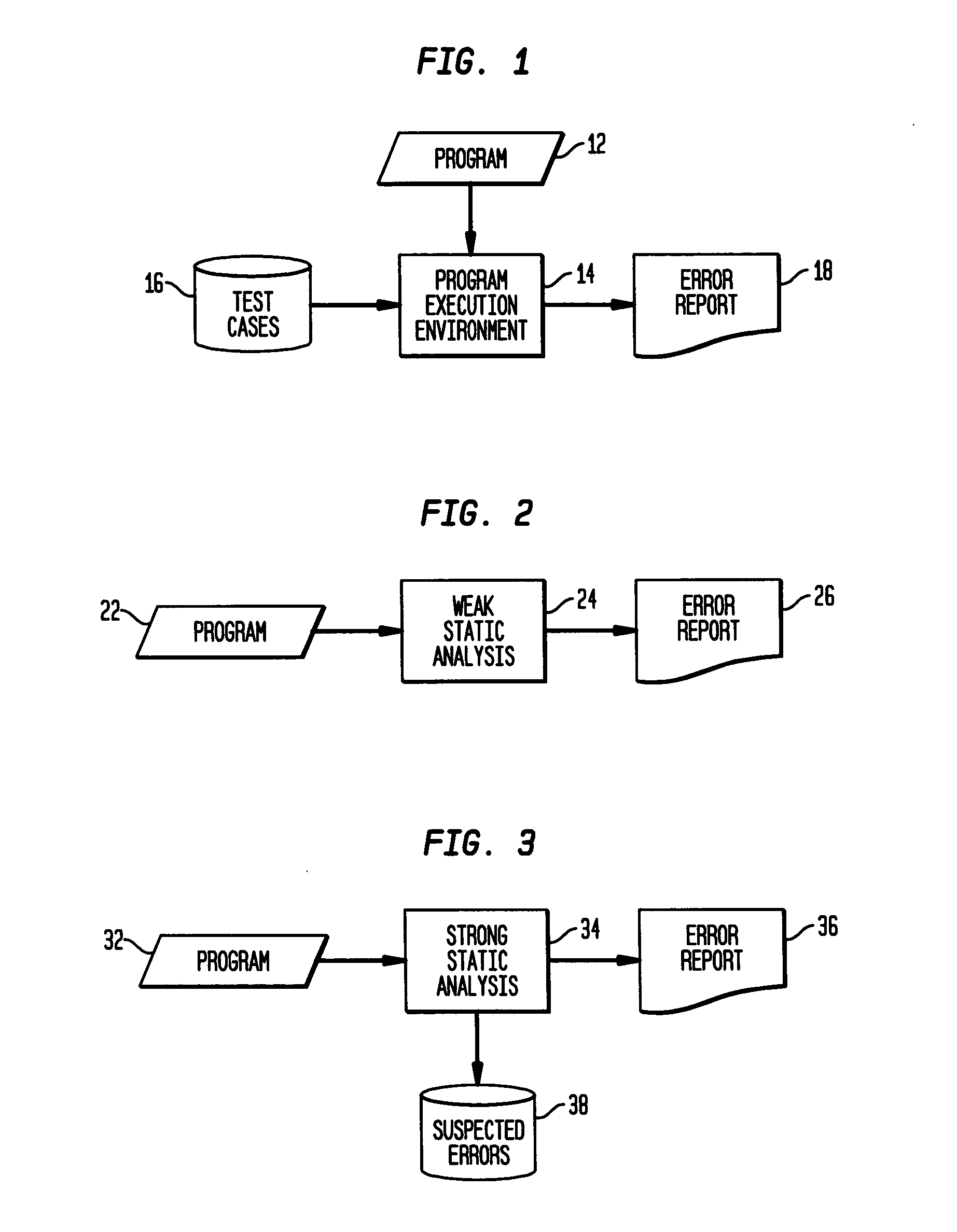

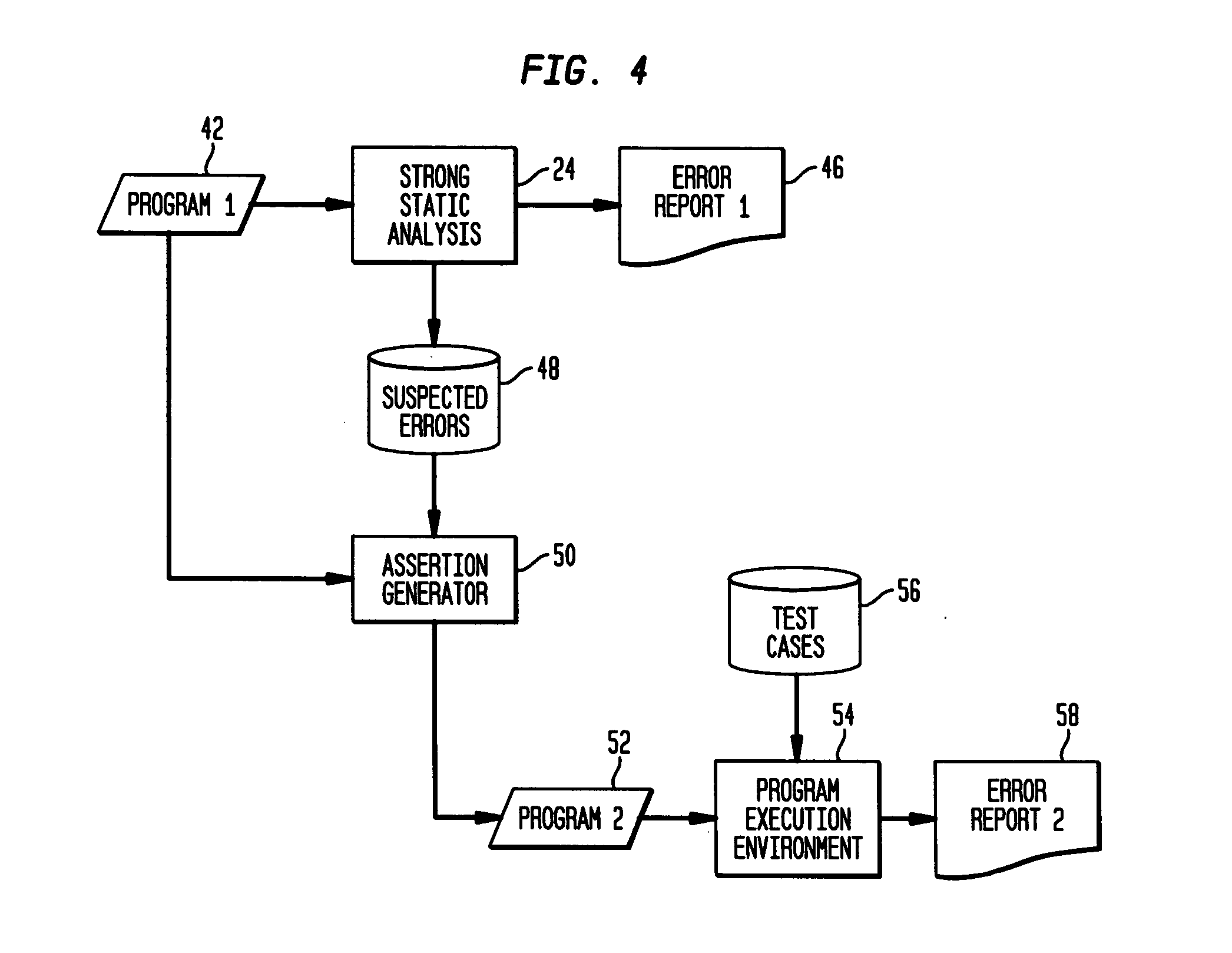

Method and system for identifying errors in computer software

InactiveUS20050066234A1Error detection/correctionSpecific program execution arrangementsTheoretical computer scienceSource code

Disclosed are a method and system for analyzing a computer program. The method comprises the steps of analyzing the program to generate an initial error report and a list of suspected error conditions, and generating a set of assertions and inserting the assertions into the program to determine if the suspected error conditions are valid. Preferably, a strong static analysis method is used to identify an initial set of error reports. When this analysis fails to determine if the condition is true or false, the condition along with the potential program error is captured to form a suspected error. Suspected errors are directed to an assertion generator to produce a monitor—that is, source code modification that is integrated with the original program. This and other inserted monitors check the conditions for the suspected error during the program execution.

Owner:IBM CORP

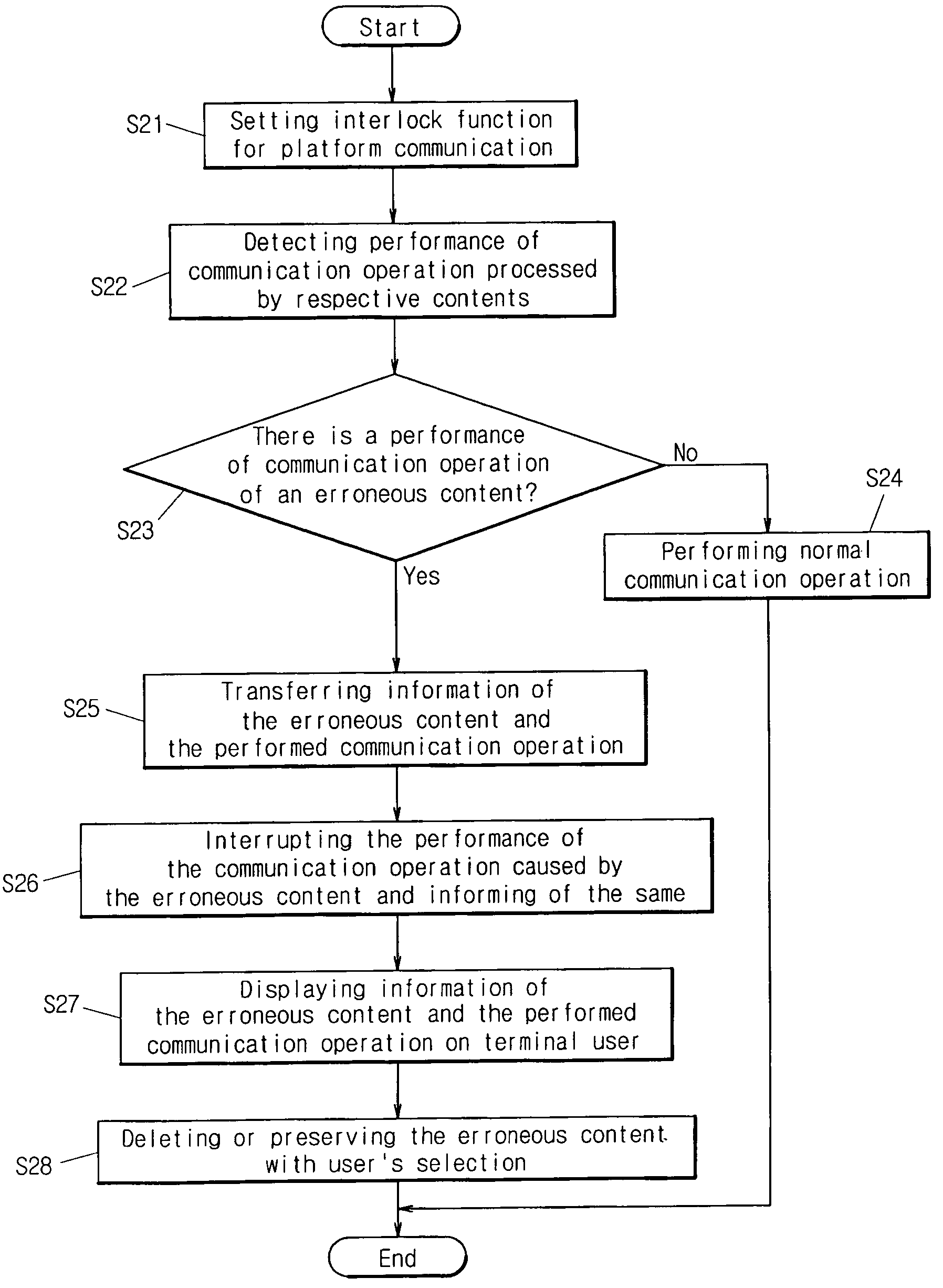

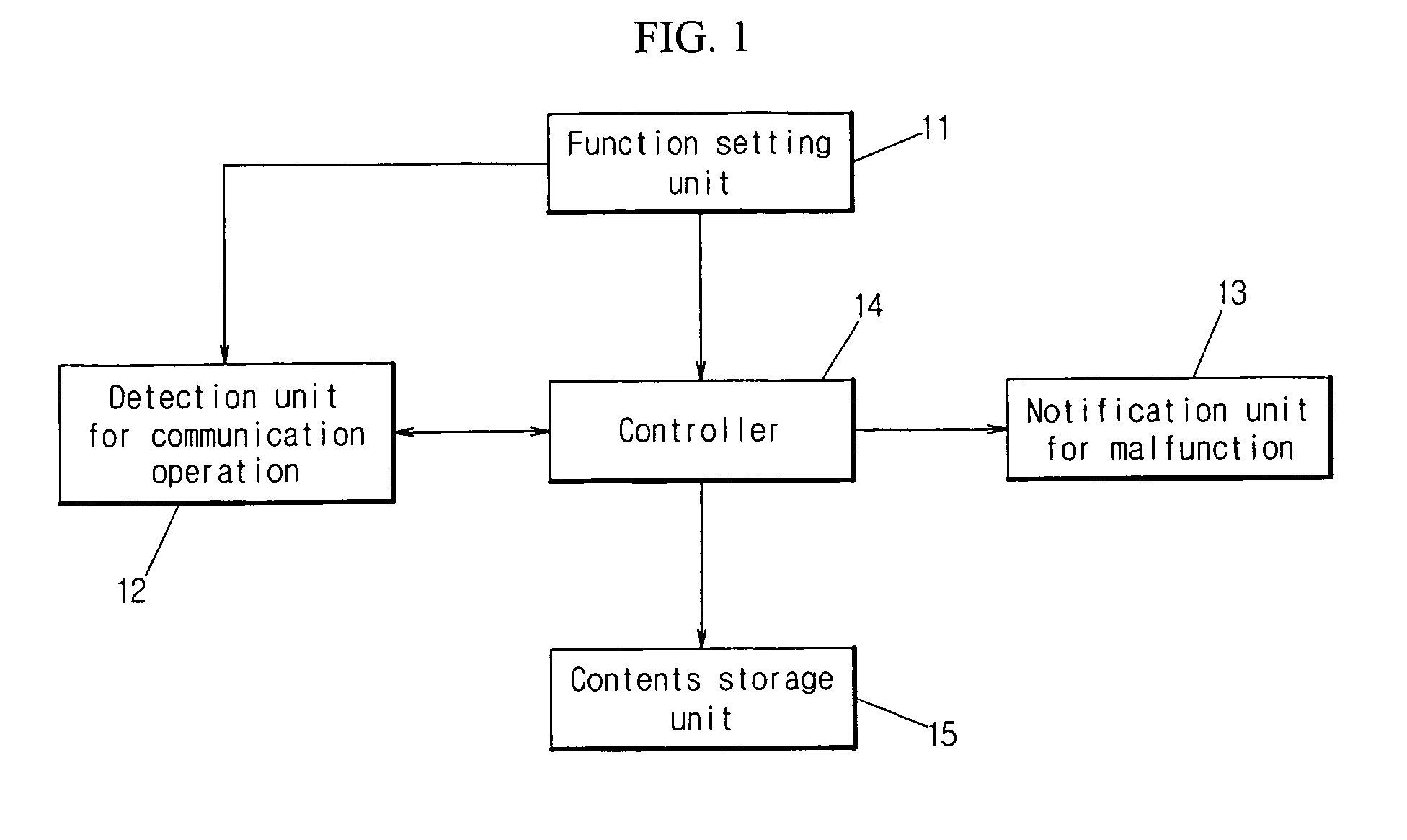

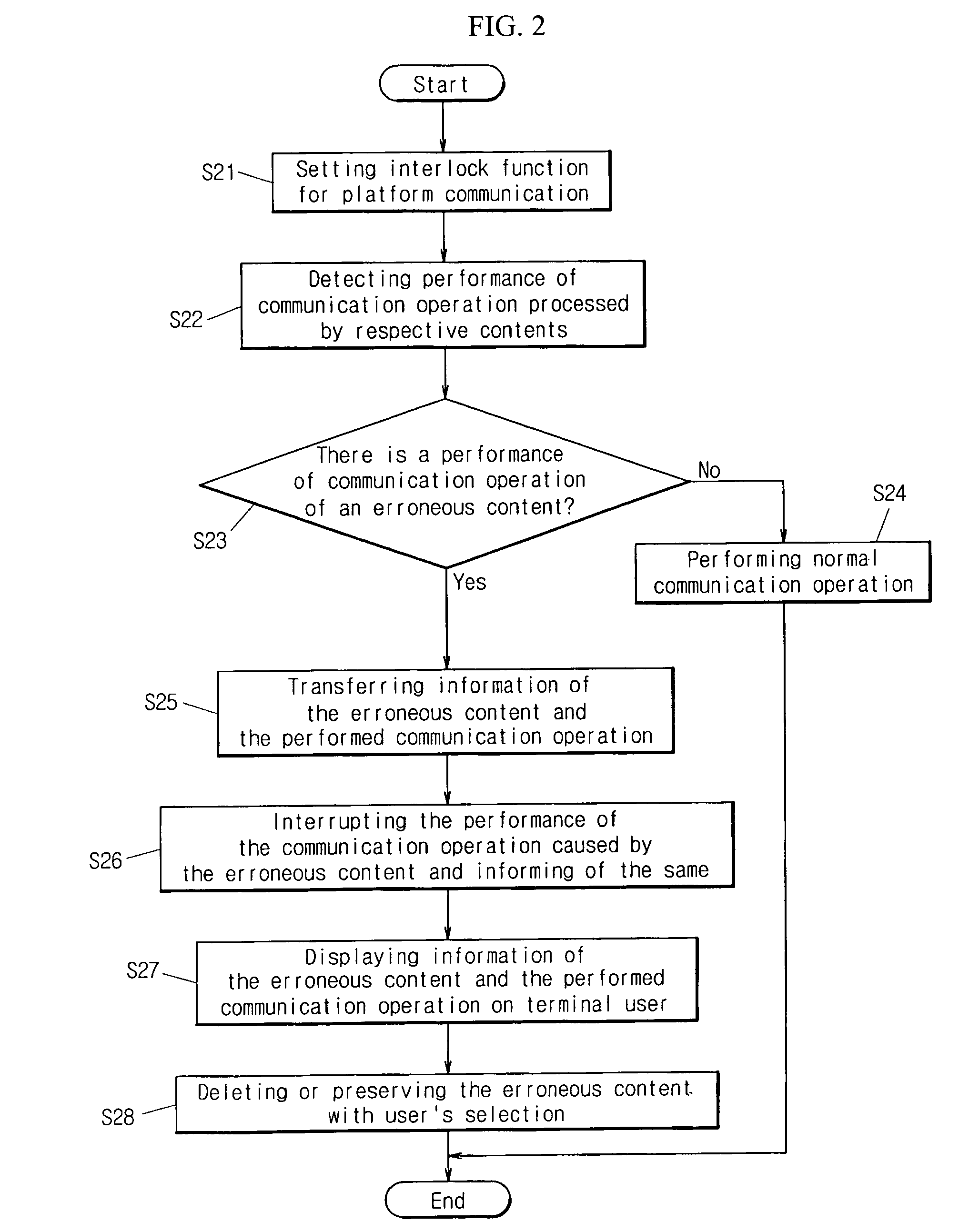

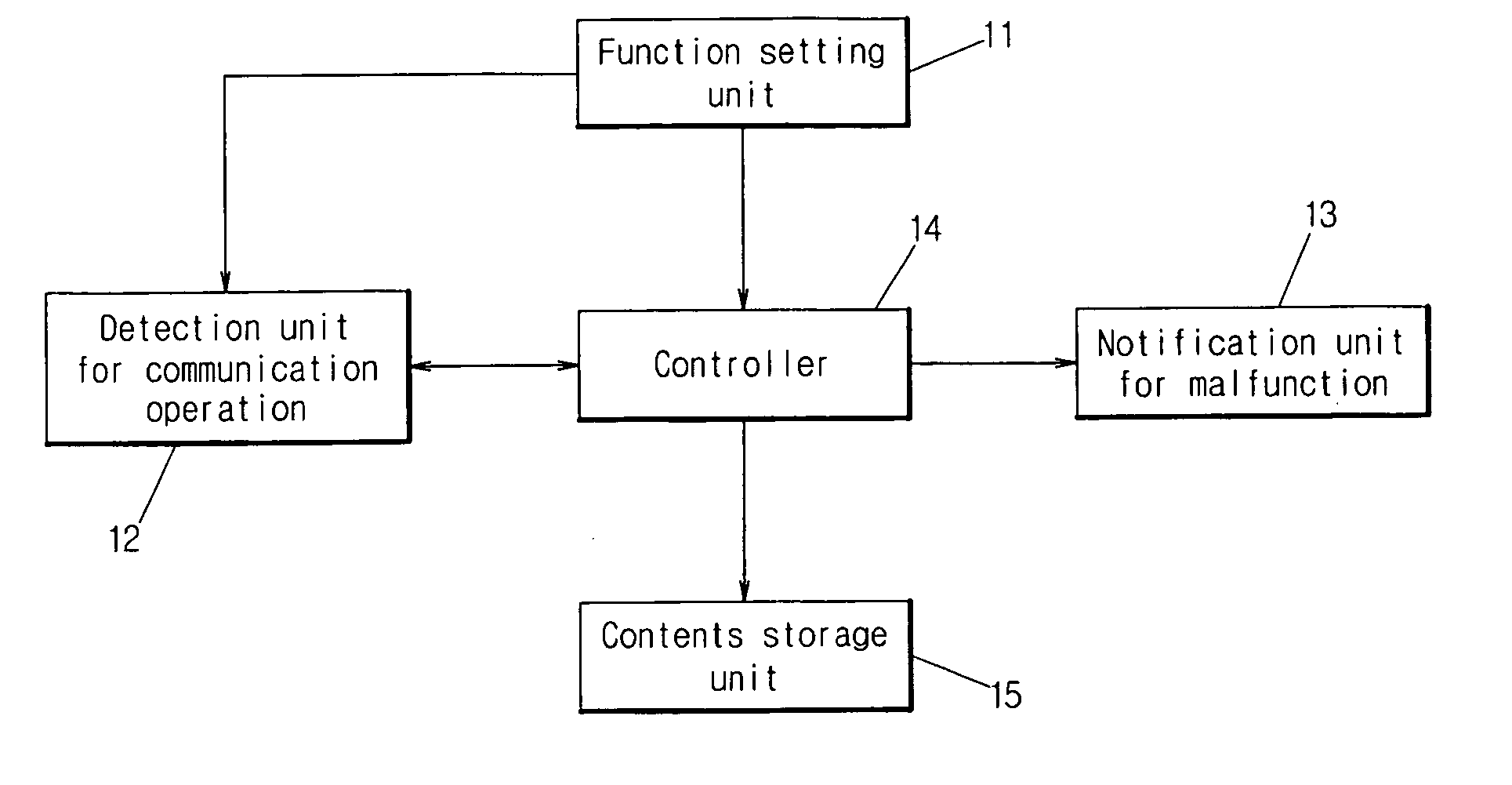

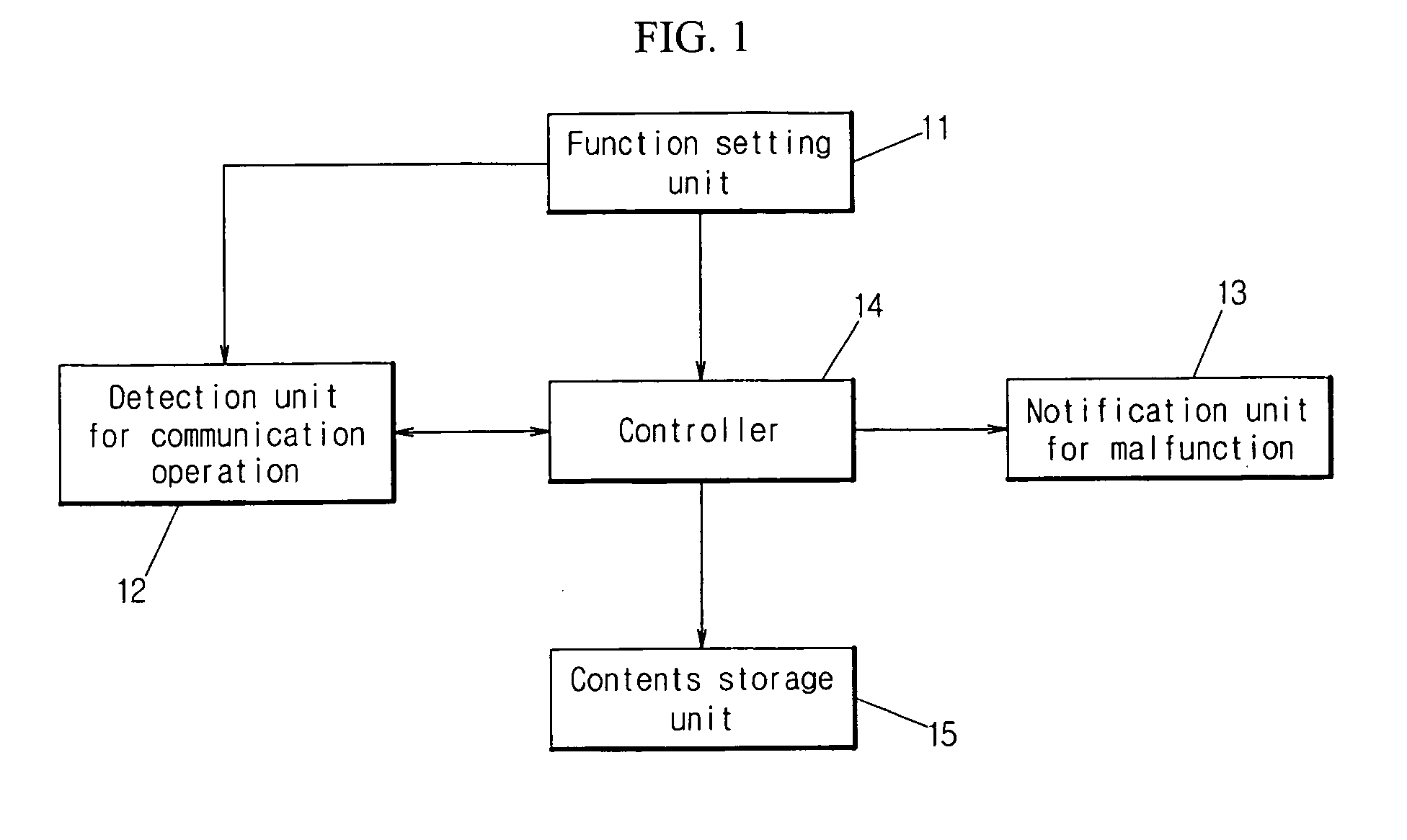

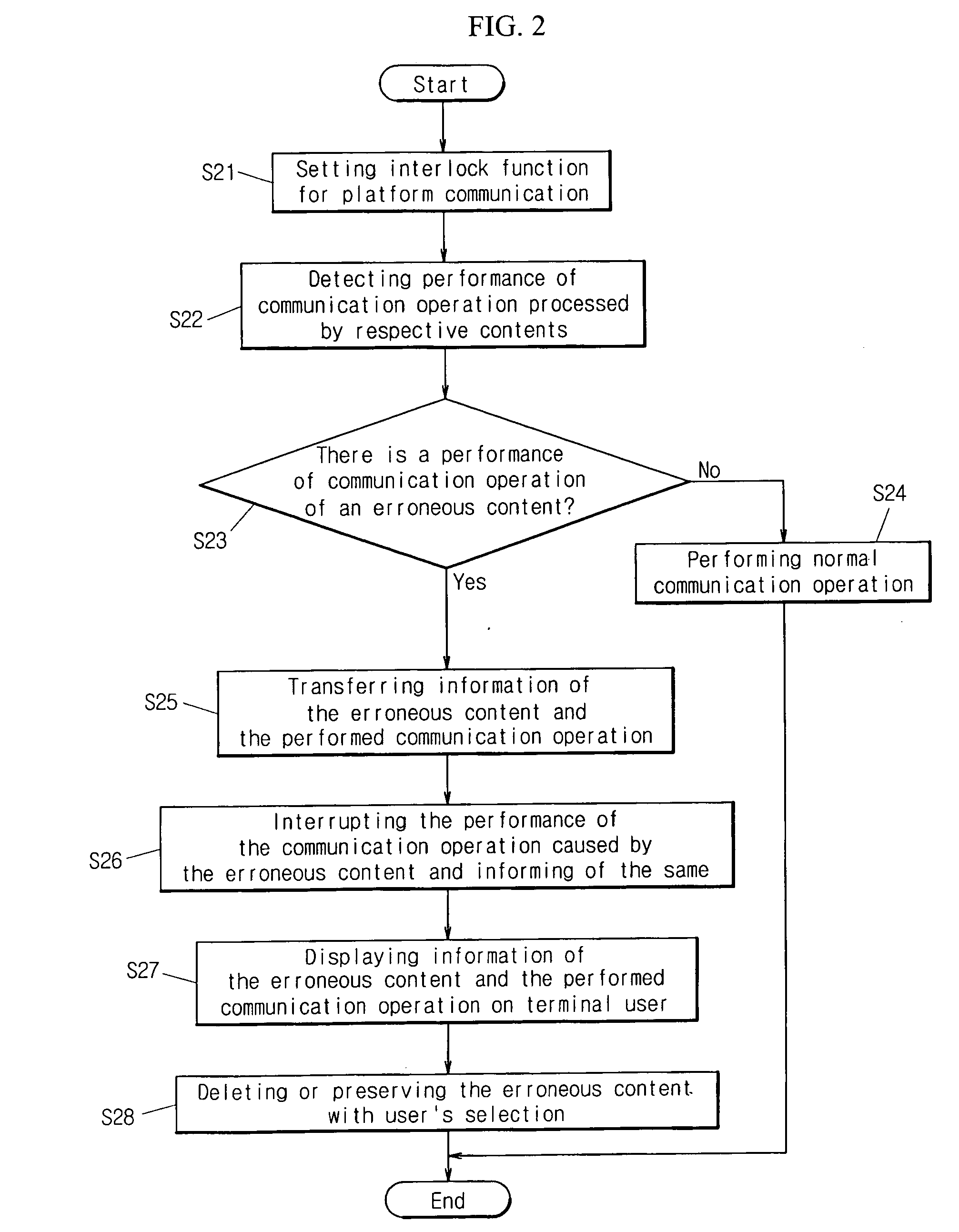

Apparatus and method for detecting communication operation resulted from an erroneous content in mobile platform

ActiveUS7831248B2Avoid performancePrevent occurrence of damageUnauthorised/fraudulent call preventionEavesdropping prevention circuitsPaymentComputer network

Disclosed are an apparatus and a method for detecting whether a content executed in a mobile platform of mobile communication terminal perform a communication operation without a user's reservation or permission, thereby preventing an unexpected communication operation. In this invention, if a content performs the communication operation due to its malfunction by a computer virus or a program error, the communication operation, such as voice calling or message transmission to unspecified communication terminal or access to arbitrary wireless internet server, is detected and interrupted. With the interruption of the unexpected communication operation, the user's damage, such as the payment of charges for communication services, is previously prevented. In case of the interruption of the communication operation, the user is informed of the erroneous content and the performed communication operation so that the user selects the corresponding contents to be deleted or preserved.

Owner:PANTECH CORP

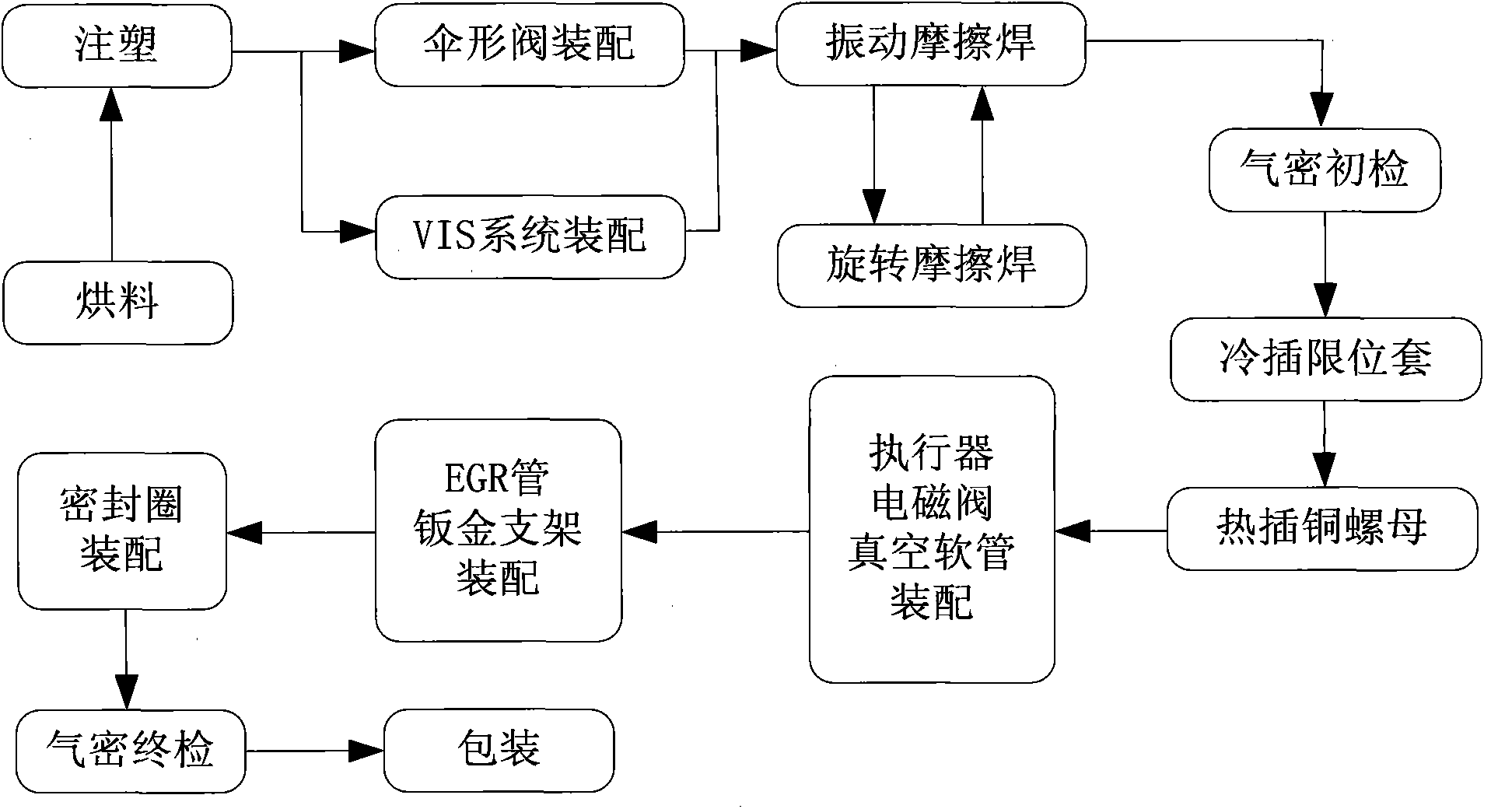

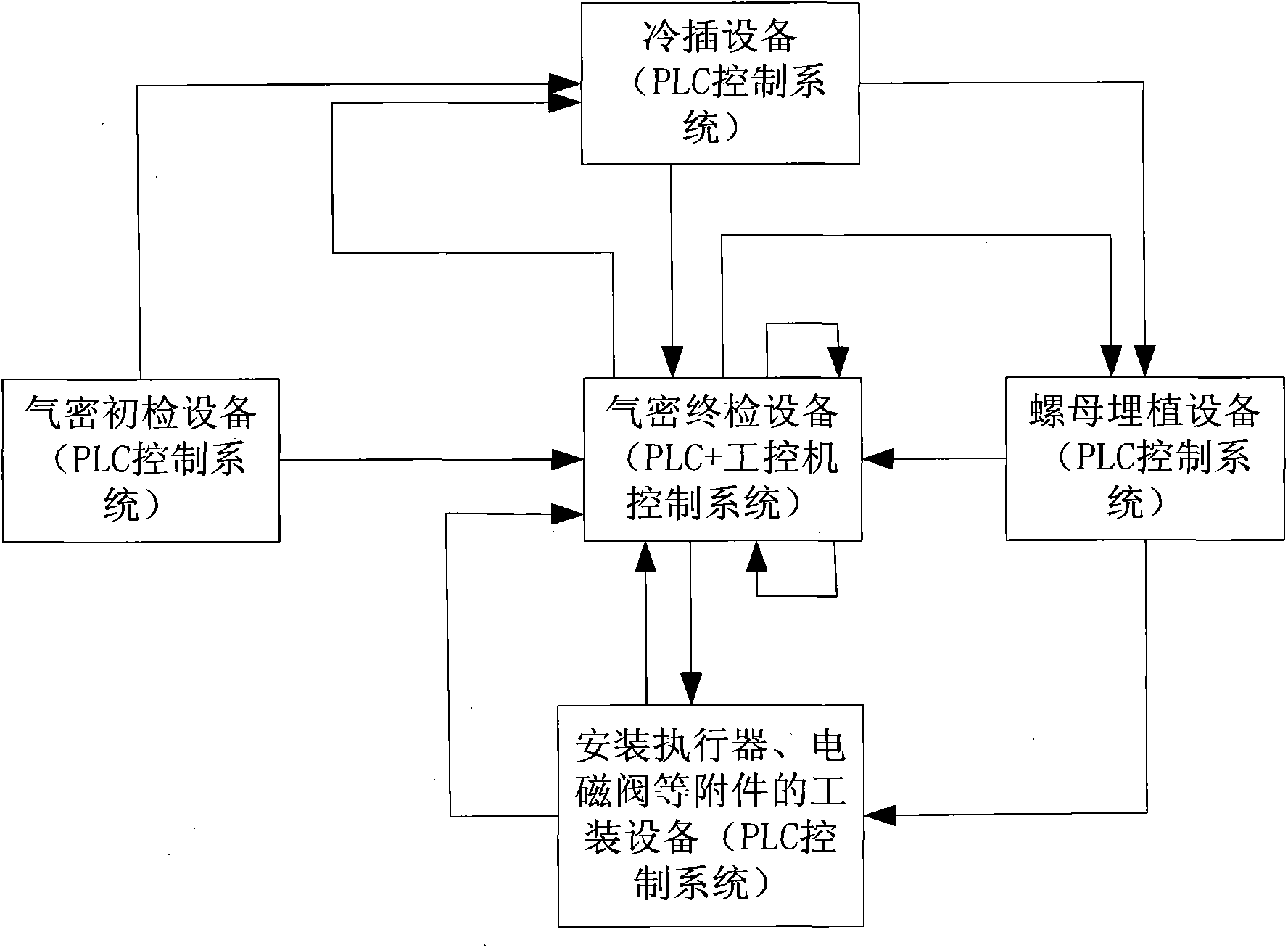

Linkage production line control method applied to intake manifold accessory installation

ActiveCN103955197AAvoid Process ErrorsReduce the failure rateTotal factory controlProgramme total factory controlSolenoid valveActuator

The invention provides a linkage production line control method applied to intake manifold accessory installation. A production line sequentially comprises an air tightness initial inspection device used for detecting whether welding is qualified or not, a cold insertion device used for pressing stop collars, a nut embedment device used for pressing copper nuts, a tool device used for installing accessories such as an intake manifold actuator and a solenoid valve, and an air tightness final inspection device used for detecting whether overall welding and accessory installation are qualified or not. According to the linkage production line control method applied to intake manifold accessory installation, before the devices operate, product number retrieval is carried out through a database system, whether missing installation or error installation exist or not is judged according to retrieval information, then, a whether a system meets operation conditions or not is judged, the working procedure error and the part missing installation error are avoided, the reject ratio of products is reduced, and production efficiency is improved; production and processing quality of each product can be tracked in the whole process through a two-dimension code technology, and therefore machining quality is improved; in addition, a client can carry out product quality tracing through two-dimension code scanning or database information retrieval.

Owner:QINGDAO HUATAO AUTOMOBILE MOLD

System and methods for processing software authorization and error feedback

InactiveUS20060253760A1Blocking may occurElectronic circuit testingDigital data processing detailsProcedure errorAuthorization

Software error feedback information, typically that associated with authorization failures due to operating system resource access checks, is automatically communicated to a software vendor with actions needed to prevent the software application error from occurring on the client computer. If possible, information associated with the software error is communicated to the client computer in order to mitigate the error by modifying how the client computer's operating system interacts with the software application so that the error may be avoided and user interaction minimized. Modifications may include automatically redirecting a resource request associated with the authorization failure in a manner such that authorization will be granted by the operating system and prevent the authorization failure due to the access check.

Owner:MICROSOFT TECH LICENSING LLC

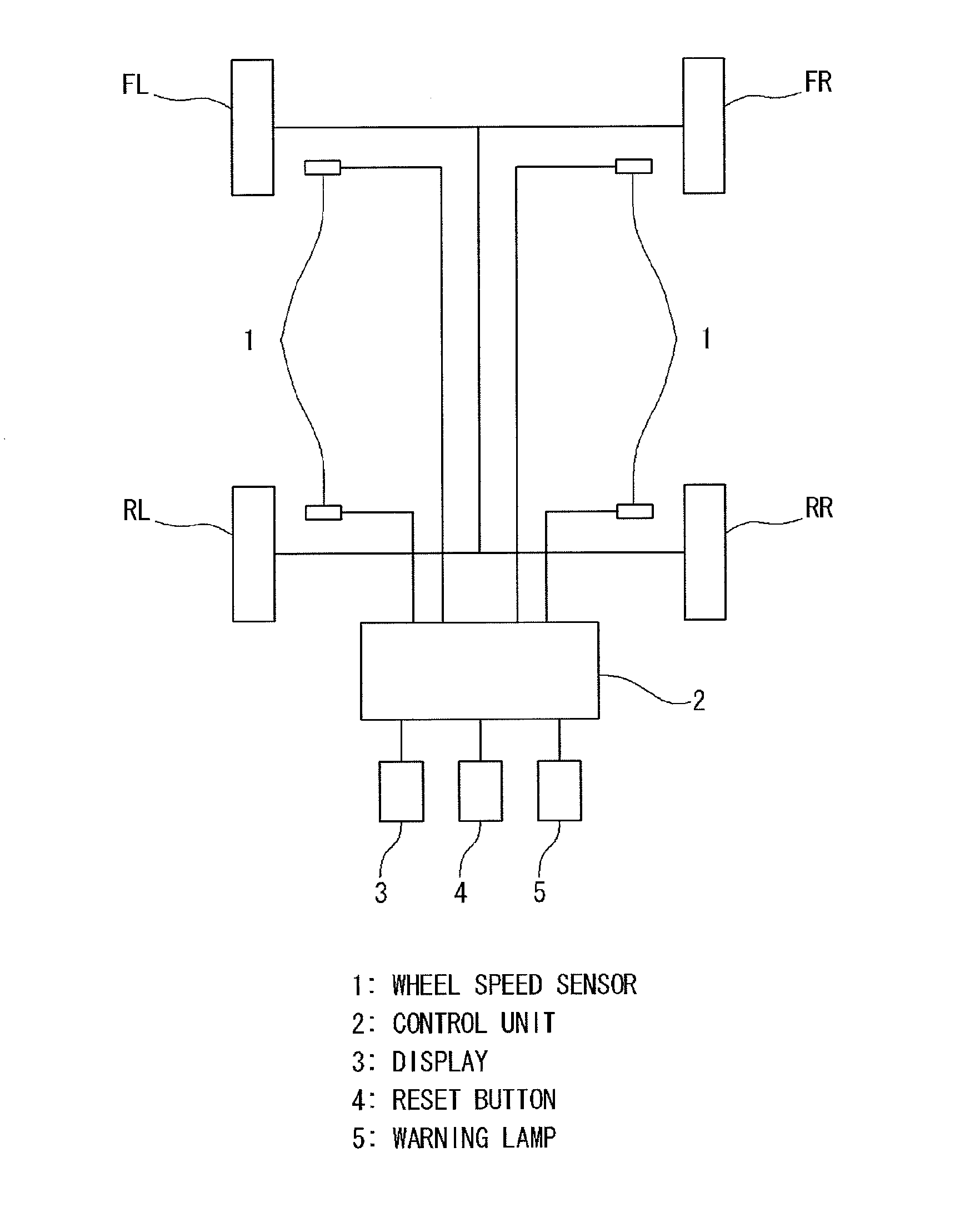

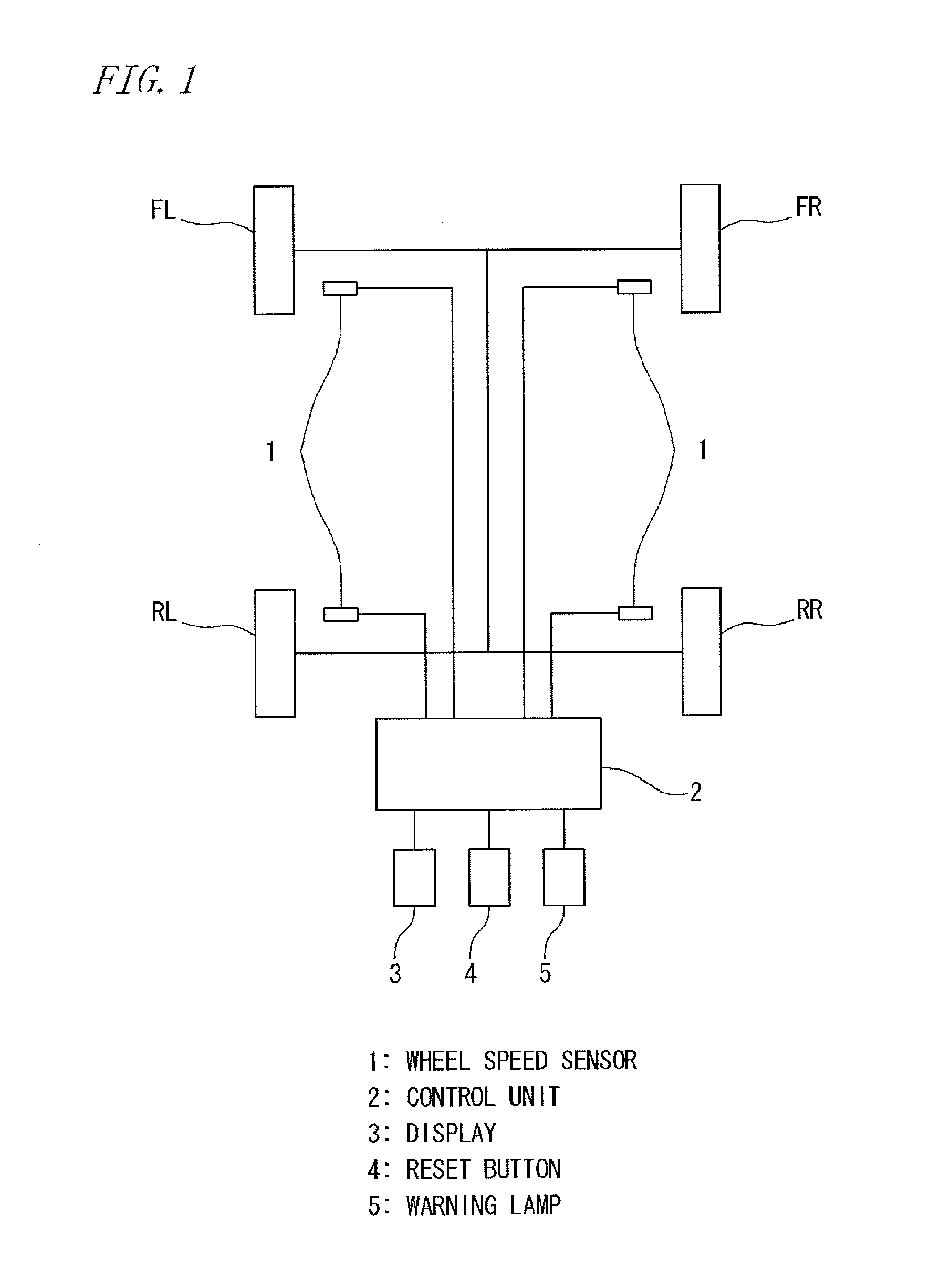

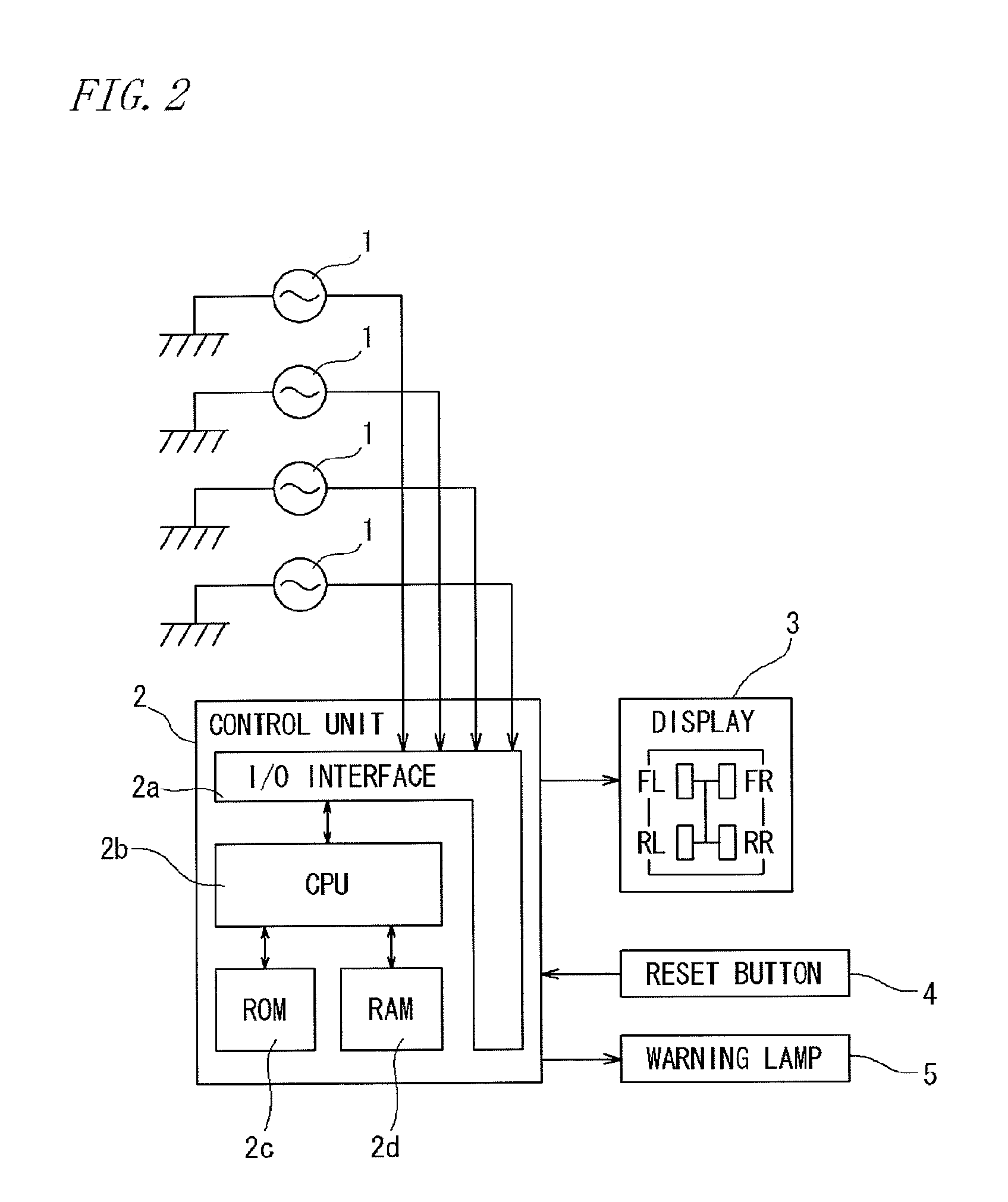

Wrong operation detection device, method, and program in tire pressure monitoring system

A wrong operation detection device is disclosed for monitoring whether or not a calibration start for determining an initial deflation index is issued in a tire pressure unadjusted state after a deflation warning in a tire pressure monitoring system for detection of deflation of a tire. The device includes comparison means for comparing a first deflation index serving as a deflation index at any time point in a period from issue of the deflation warning to vehicle stop after the issue of the warning, with a second deflation index serving as a deflation index obtained after the calibration start; detection means for detection of wrong operation of a reset button based on a comparison result by the comparison means; and warning means for issuing a warning when the detection means detects the wrong operation.

Owner:SUMITOMO RUBBER IND LTD

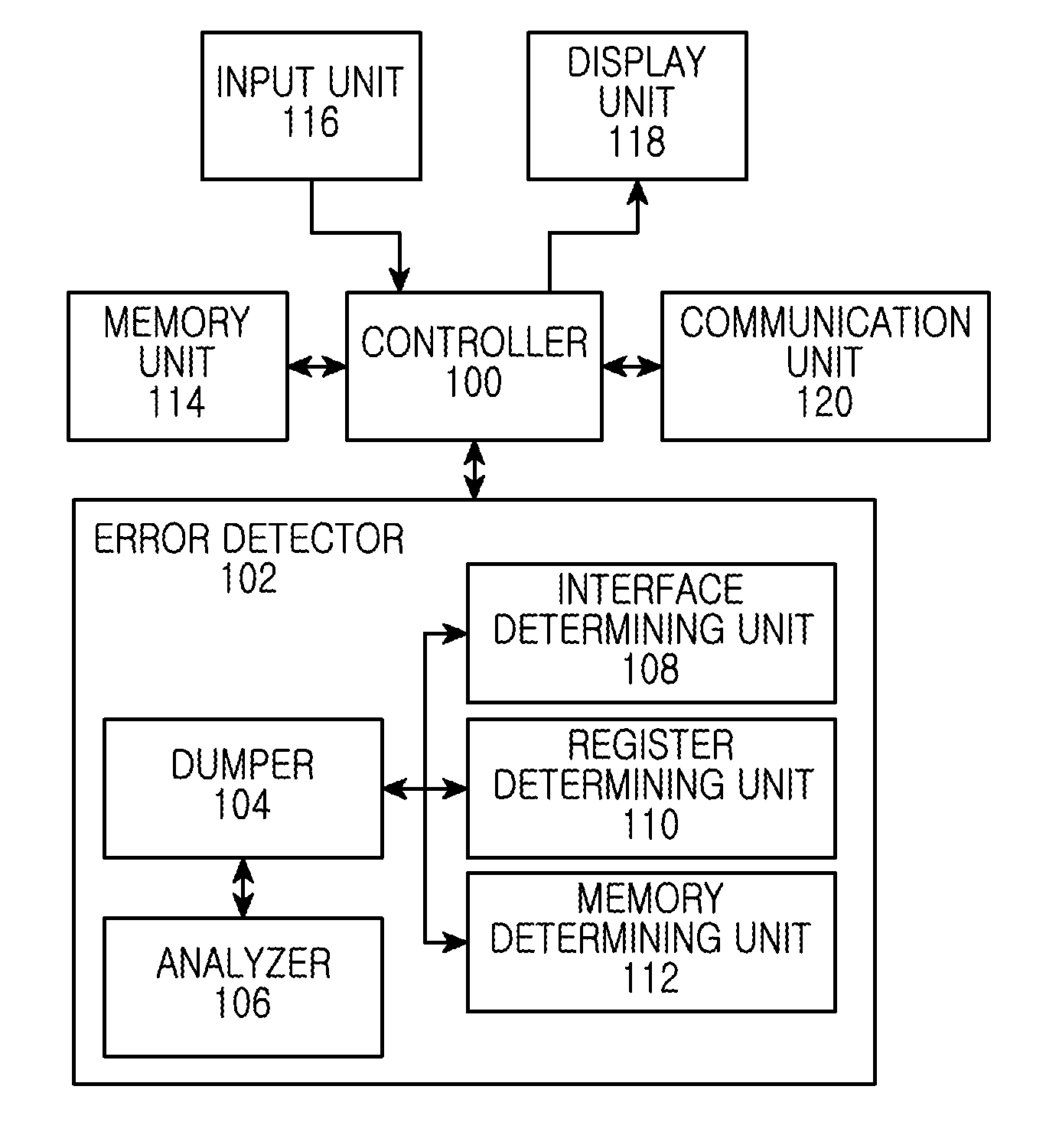

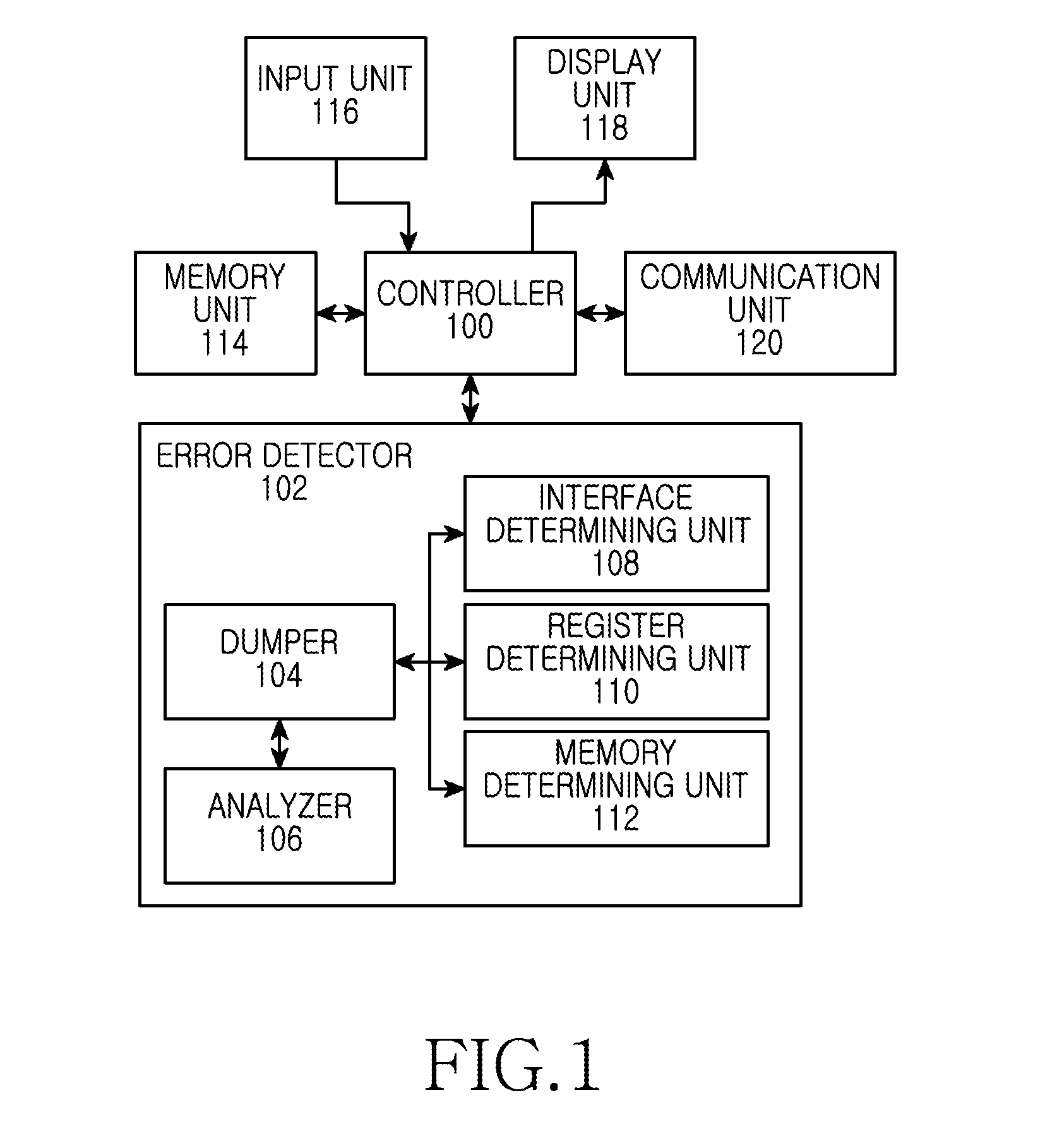

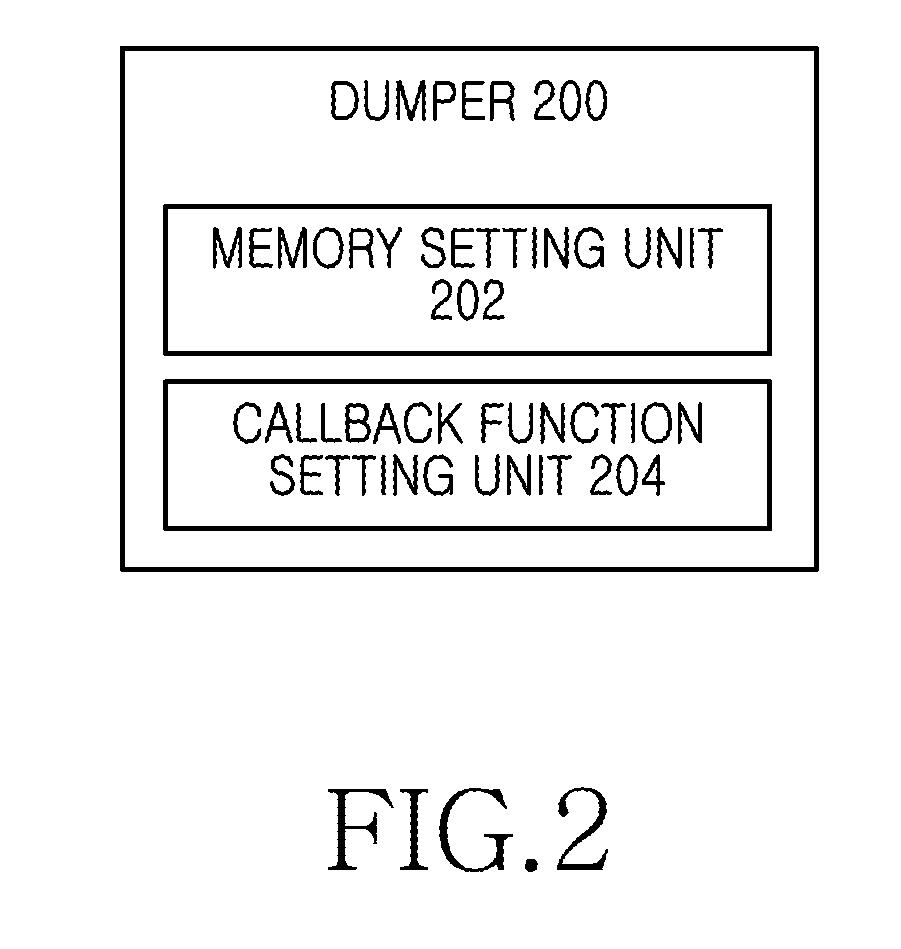

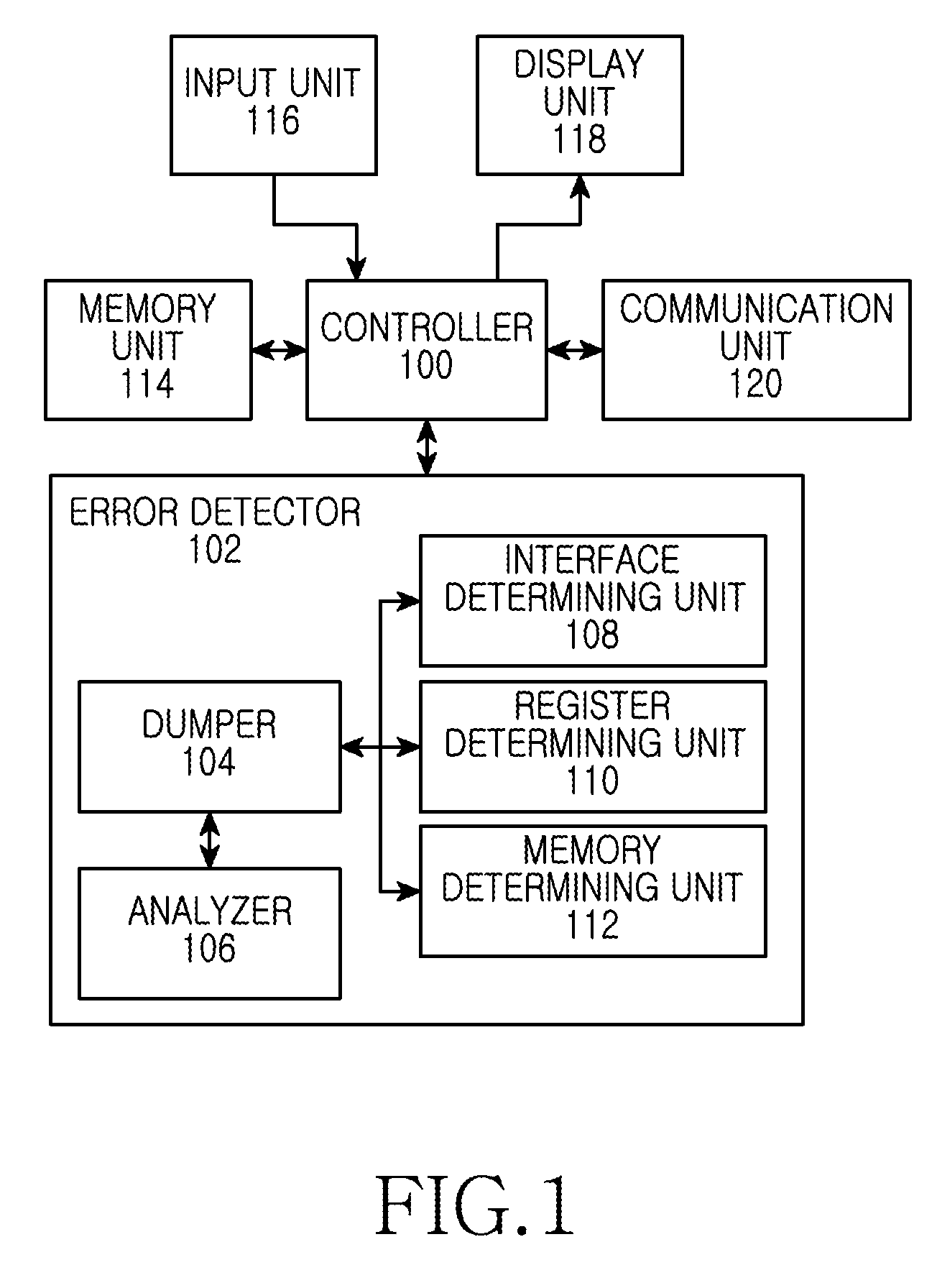

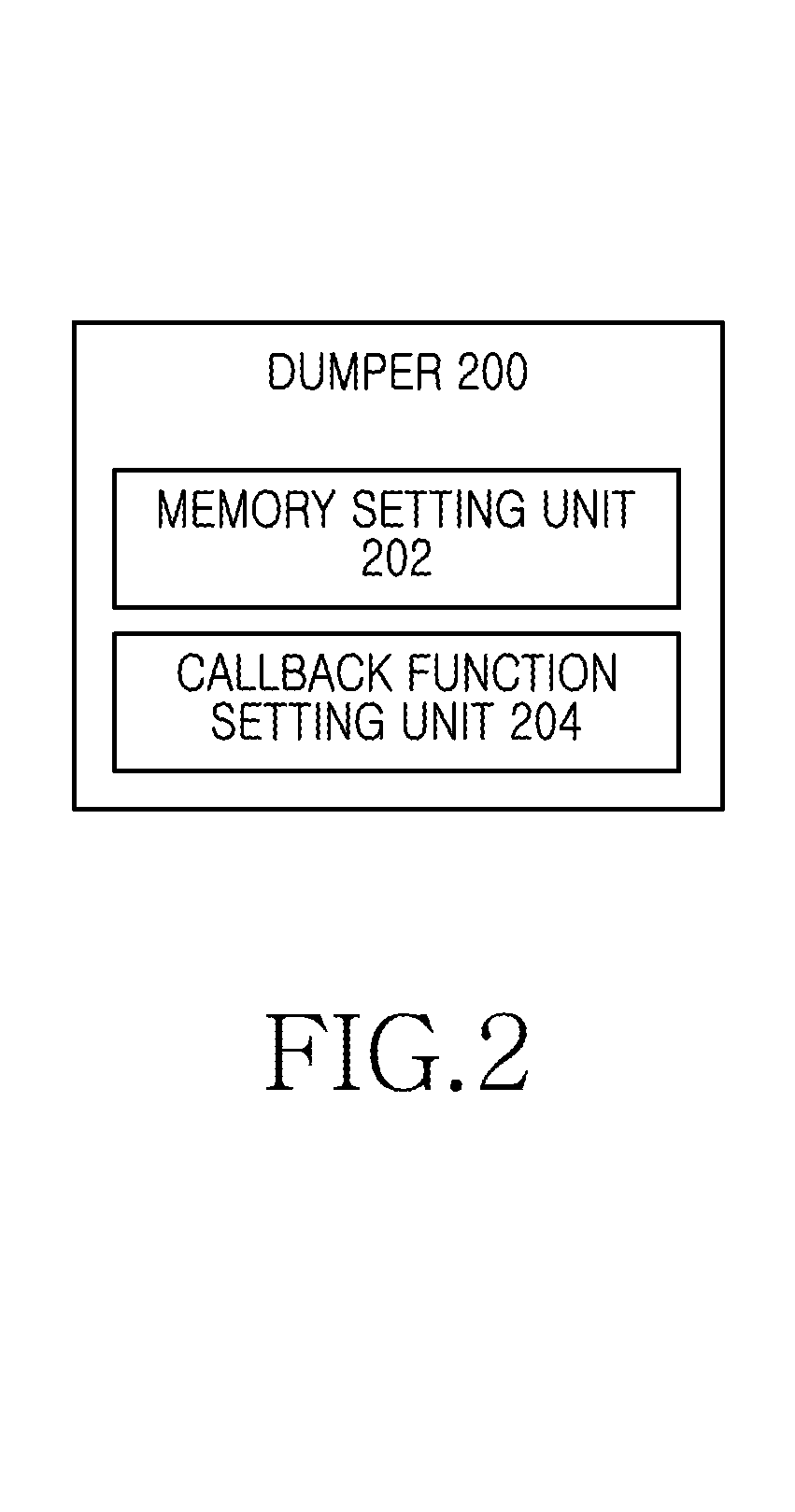

Apparatus and method for analyzing error generation in mobile terminal

Owner:SAMSUNG ELECTRONICS CO LTD

Blade machining process error prediction method based on extended error flow

InactiveCN103440416AReduce reworkImprove processing qualitySpecial data processing applicationsGeometric errorCoupling

The invention discloses a blade machining process error prediction method based on extended error flow. The method is used for solving the technical problem that only geometric error sources are considered when multi-procedure rigid body part assembling or machining processes are adopted as the study object according to an existing error flow method. According to the technical scheme, the method comprises the steps that a model drive is adopted for conducting process monitoring, errors generated by a geometric positioning error source and errors generated by a force-carrying deformation error source are timely predicted, an error coupling and a transmission mechanism are studied, and a machining process error coupling modeling scheme is designed; infinitesimal division is conducted on a blade part through a grid division thought, and deformation analyses are converted to coordinate transformation of an infinitesimal coordinate system; a multi-source and multi-procedure error coupling model based on the extended error flow is built, and a composition error prediction model based on the error coupling model is given on this basis. According to the blade machining process error prediction method based on the extended error flow, working personnel can be helped to timely find manufacturing defects of the blade and correct and adjust the blade, reworking times are reduced and machining quality and efficiency are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pump body shell production line

PendingCN109014959ARealize automatic processing and productionReduce uncertaintyOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses a pump body shell production line. The pump body shell production line comprises the production procedures of shape milling and grinding, stepped hole boring and milling, bearing hole machining, water mouth lathing, overflow hole drilling, installation hole drilling, bolt platform drilling and milling and water seal platform finish lathing and further comprises a material feeding line, a chain plate line and a transfer robot, wherein the shape milling and grinding further comprises milling and grinding detection, and the stepped hole boring and milling are performed through delivery of the material feeding line after the milling and grinding detection; and between the stepped hole boring and milling and the material feeding line, a first module actuator performs detection with a detection device, and meanwhile, pump body shells are transferred. By means of the pump body shell production line, automation machining production of the pump body shells is realized, meanwhile, automatic detection can be performed, and staying between working procedures and working procedure errors appearing in working procedure transfer connection are avoided; and by means of programmed operations, the uncertainty of manual operations is reduced, meanwhile, the efficiency is improved, high-quality operations and detection are realized, and the market competitiveness is improved.

Owner:深圳市祁科作物科技有限公司

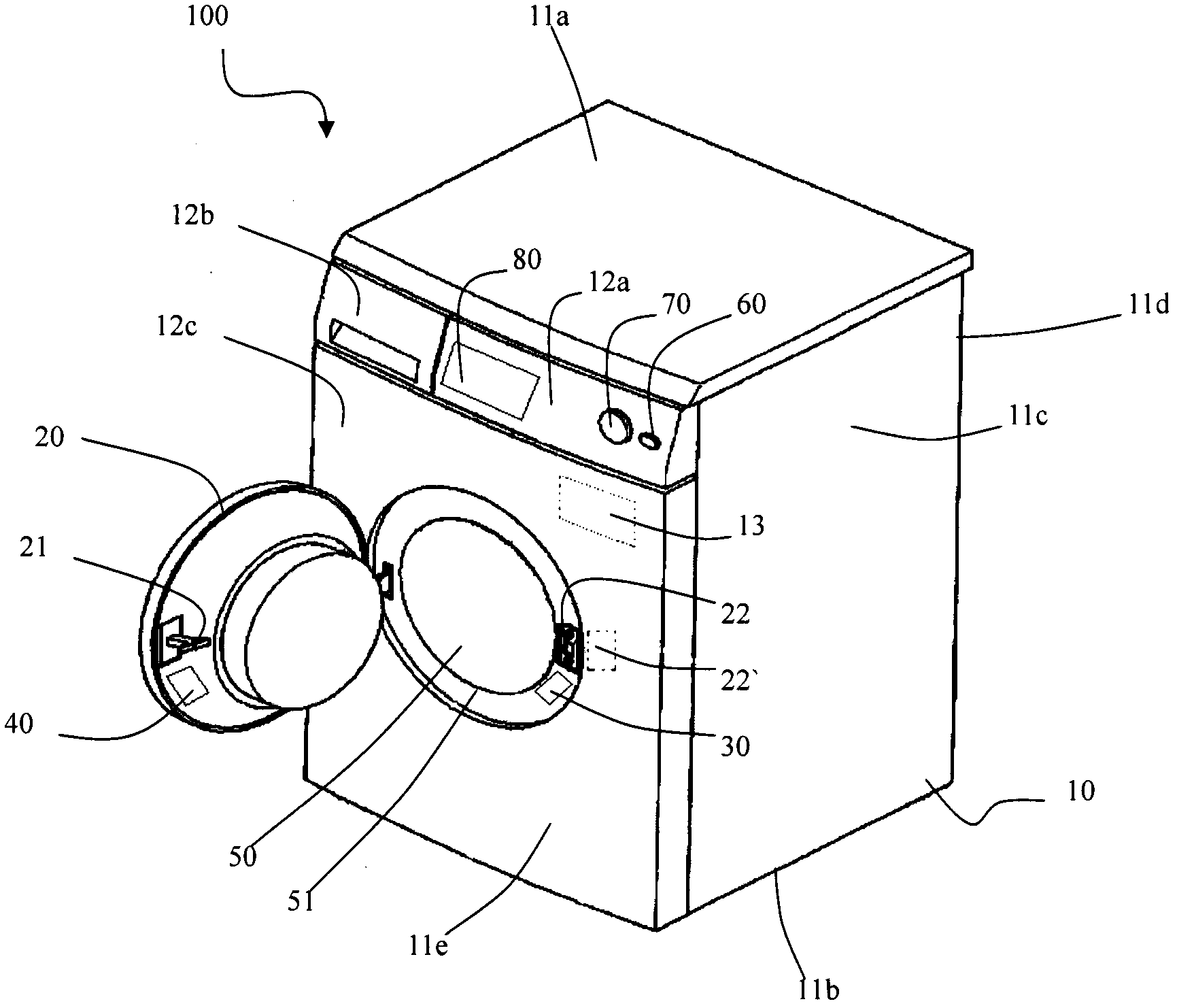

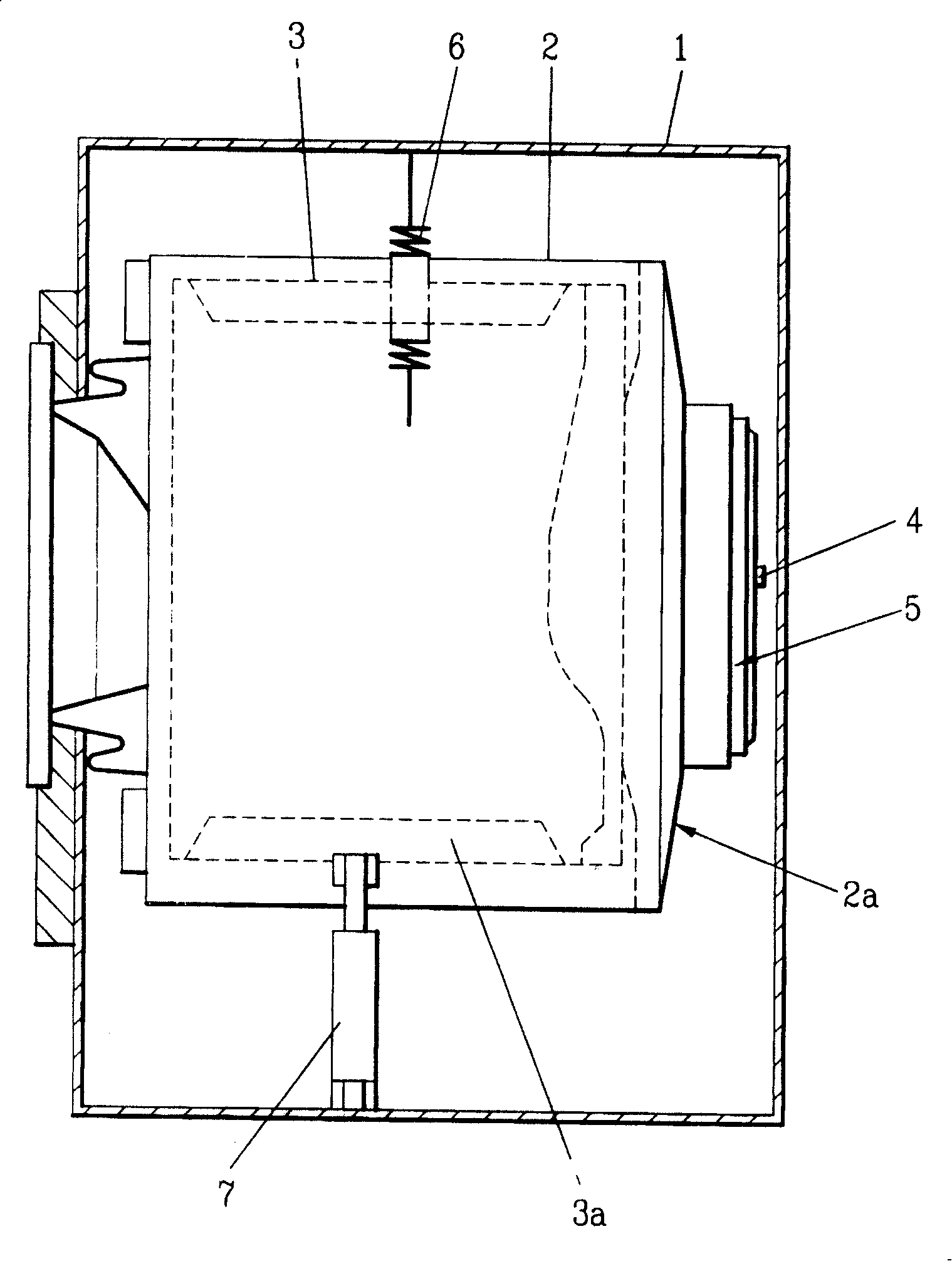

Washing machine and control method thereof

InactiveCN103046294AAvoid errorSave the process of reporting errorsNon-mechanical controlsOther washing machinesMechanical engineeringProcedure error

A washing machine (100) includes a washing machine body (10), a cylinder (50), a washing machine door (20), a locking buckle (21), a door lock switch (22), an electromagnet part (30) and an attracted part (40), wherein a main controller (13) and the cylinder (50) are arranged inside the washing machine body (10) and the door lock switch (22) is used for locking and unlocking the washing machine door (20). When a washing machine start key (60) is pushed, the electromagnet part (30) can apply an instant attraction to the attracted part (40) so that the locking buckle (21) is automatically locked in the door lock switch (22). The washing machine door (20) is capable of being attracted and locked automatically. Washing clothes procedure errors can be avoided and the time and the process for handling the procedure errors are omitted. Besides, a control method thereof is further provided.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Apparatus and method for detecting communication operation resulted from an erroneous content in mobile platform

ActiveUS20060084428A1Avoid performancePrevent occurrence of damageUnauthorised/fraudulent call preventionEavesdropping prevention circuitsPaymentComputer network

Disclosed are an apparatus and a method for detecting whether a content executed in a mobile platform of mobile communication terminal perform a communication operation without a user's reservation or permission, thereby preventing an unexpected communication operation. In this invention, if a content performs the communication operation due to its malfunction by a computer virus or a program error, the communication operation, such as voice calling or message transmission to unspecified communication terminal or access to arbitrary wireless internet server, is detected and interrupted. With the interruption of the unexpected communication operation, the user's damage, such as the payment of charges for communication services, is previously prevented. In case of the interruption of the communication operation, the user is informed of the erroneous content and the performed communication operation so that the user selects the corresponding contents to be deleted or preserved.

Owner:PANTECH CORP

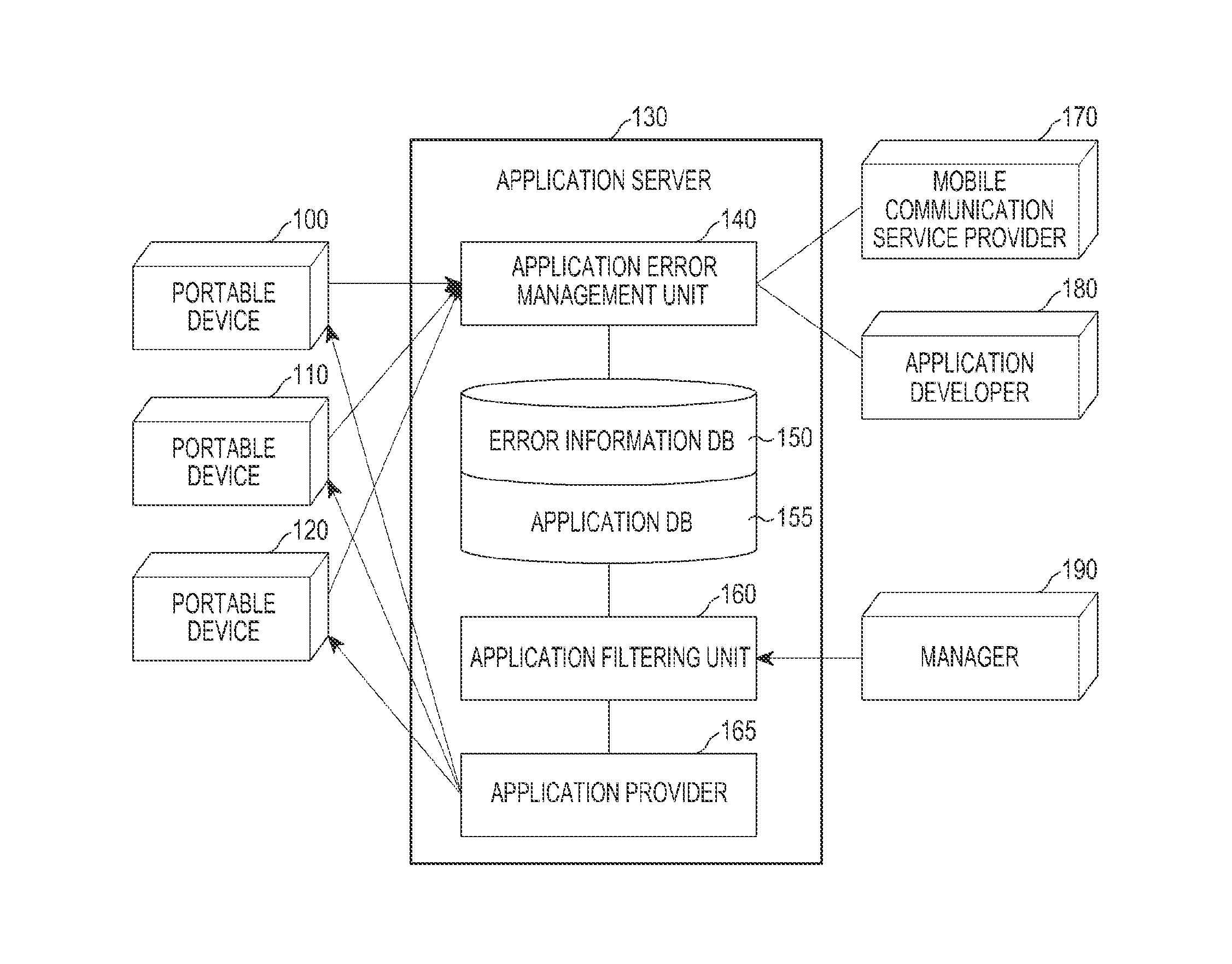

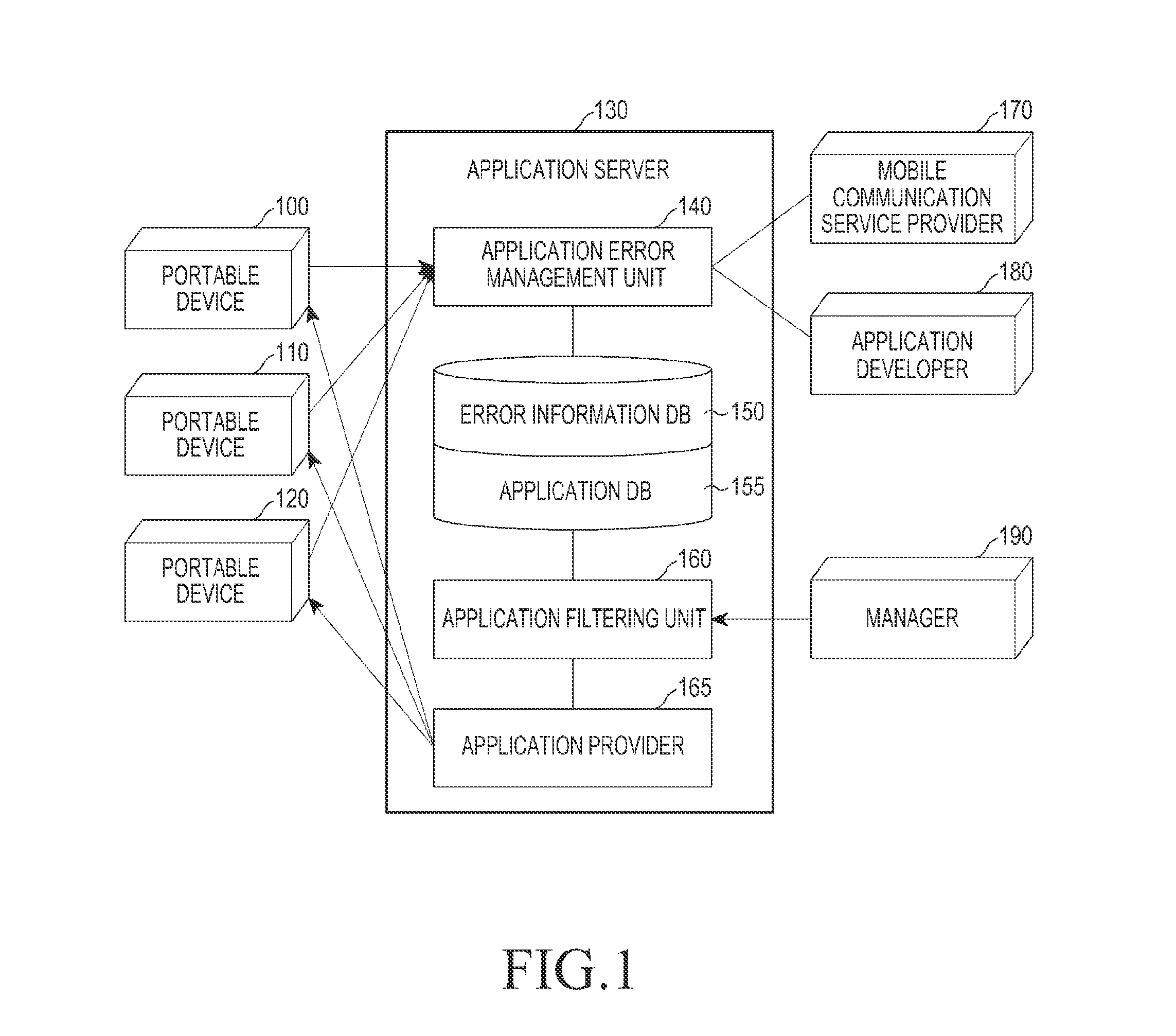

Apparatus and method for managing application error

InactiveUS20140324891A1Avoid exposureDigital data information retrievalDigital data processing detailsSoftware engineeringComputer science

Methods and apparatus are provided for managing an application error. Error record information on at least one application in which an error has occurred is collected from at least one portable device. The collected error record information is stored in a table that maps error information of each application. An application list provision request is received from a portable device. At least one application to be filtered from an application list is identified based on the error information of each application mapped in the table. The application is filtered from the application list to generate a filtered application list. The filtered application list is provided to the portable device.

Owner:SAMSUNG ELECTRONICS CO LTD

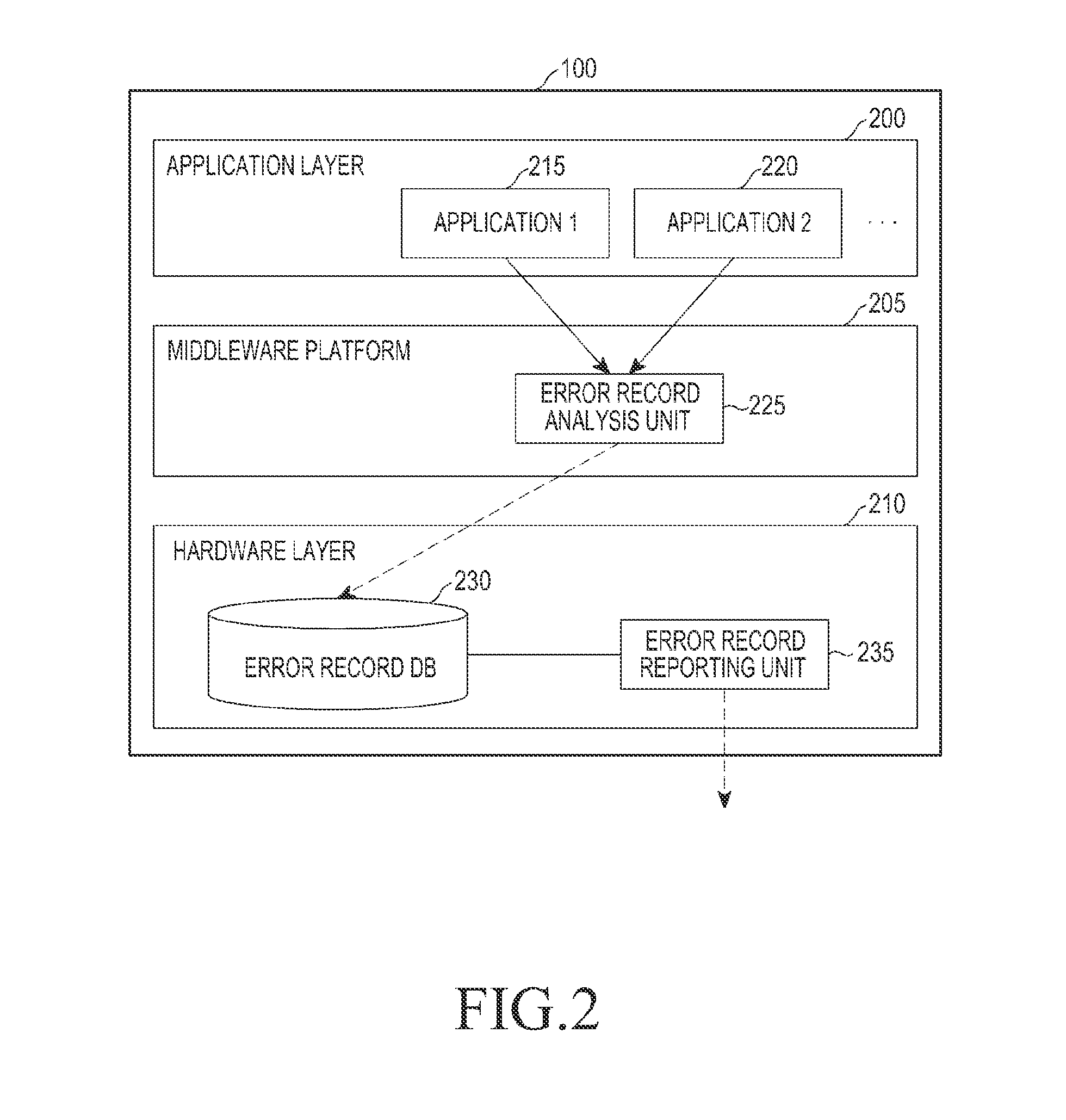

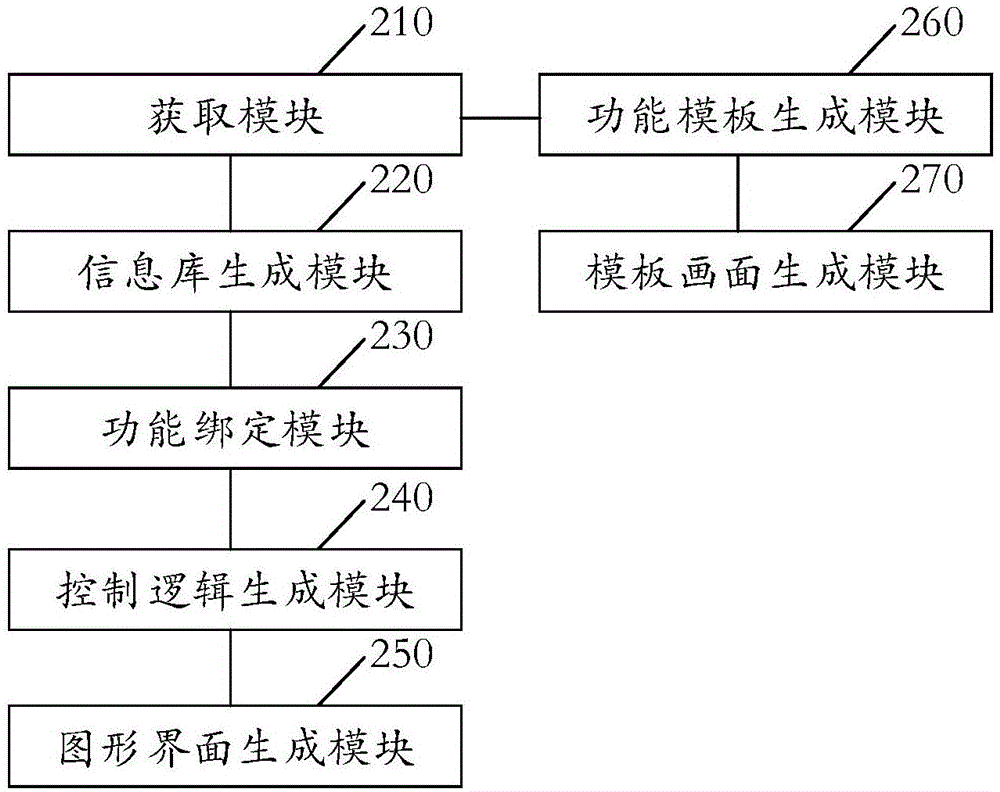

Automatic generation method and device for compressor control system

ActiveCN106224278AReduce error rateReduce the difficulty of on-site servicePump controlNon-positive displacement fluid enginesInformation repositoryHuman–machine interface

The invention relates to the field of compressor control, and discloses an automatic generation method and device for a compressor control system. The method includes the steps that measured point table data of a compressor unit are acquired and recognized; a measured point information base is generated according to the measured point table data, whether the measured point table data are correct and available or not is checked, and otherwise the measured point table data are modified; a graphical interface is configured, the measured point information base serves as a data source to be bound with the control function of the compressor unit, and compressor performance parameters and control parameters are configured; according to the configuration, reserved port variables are written into a PLC template program through PLC data drive, and thus control logic is generated; and according to the configuration, numerical value display in an SCADA picture template is bound with the animation, so that a human-computer interface is generated. The automatic generation method and device for the compressor control system can be applied to various platforms, time and labor are saved, the program error rate is lowered, the development period is shortened, working efficiency is greatly improved, and field service difficulty is lowered.

Owner:SHENYANG BLOWER WORKS GRP AUTOMATIC CONTROL SYST ENG

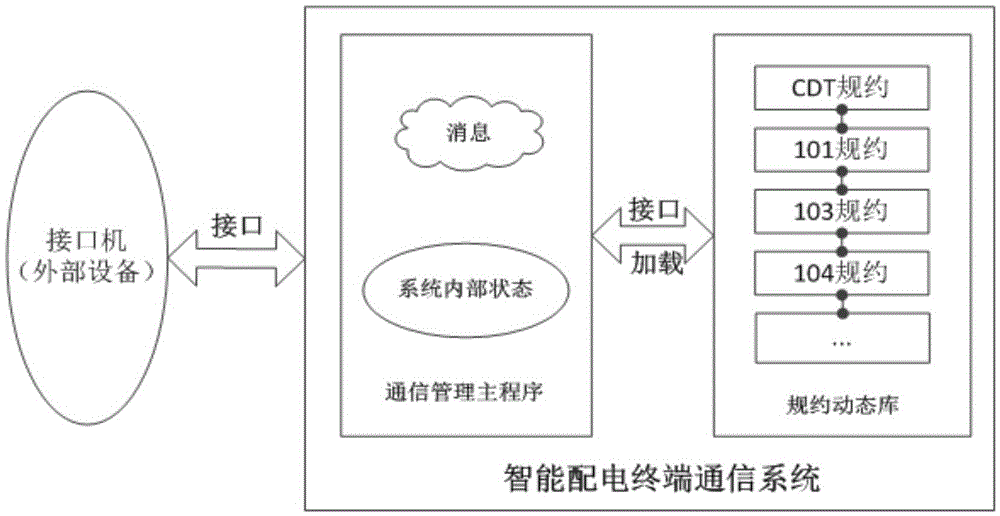

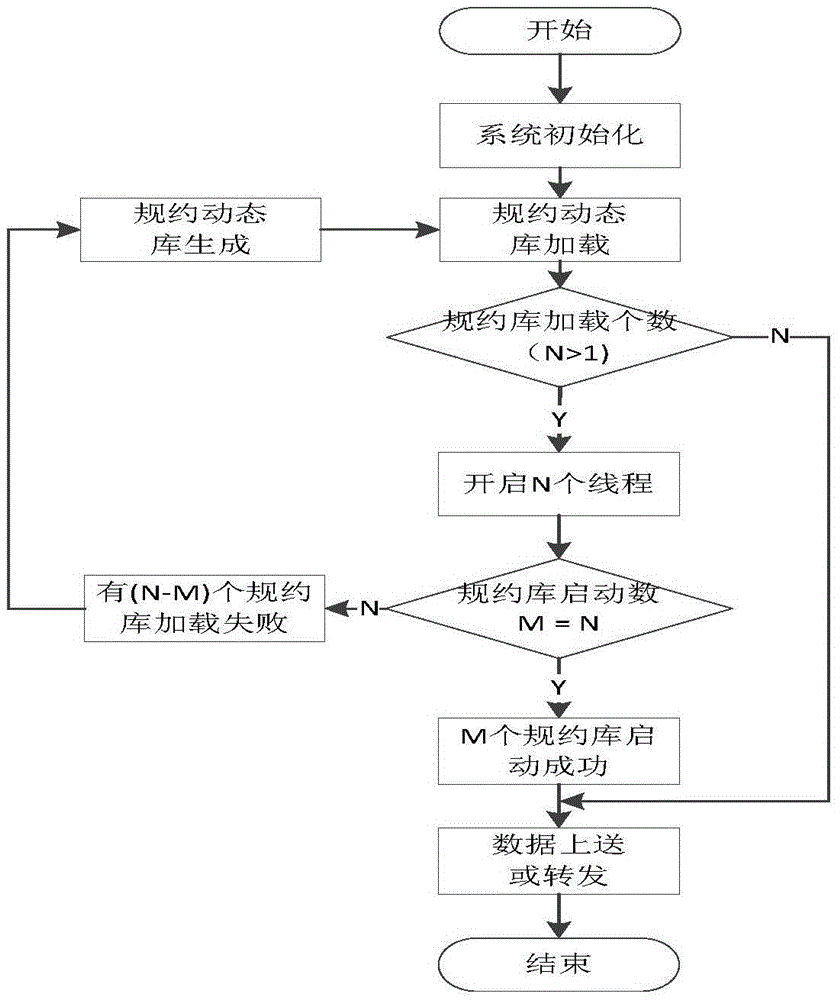

Intelligent power distribution terminal communication weak coupling modularized system and method

The invention discloses an intelligent power distribution terminal communication weak coupling modularized system and method. The system comprises that: different types of protocol programs are integrated in a protocol dynamic library; a communication management main system provides an interface for loading the protocol programs in the protocol dynamic library; the communication management main system starts independent threads according to the loaded protocol programs, binds the threads with the loaded protocol programs, organizes data into the data types demanded by protocols and transmits to various different protocols; and the protocol dynamic library processes the messages issued by the communication management main system or submitted by a client, obtains useful data information, stores in corresponding caches and issues or submits to other application programs according to standard protocol types and packaging formats in the protocols. The system and the method of the invention has the advantages that the program modularization is high; the functions of each module are mutually independent; the portability and expansibility of the programs are good; starting and stopping of the protocol library can be controlled freely; the system cost is low; and the errors of the protocol programs can be positioned more accurately.

Owner:SHANDONG LUNENG SOFTWARE TECH

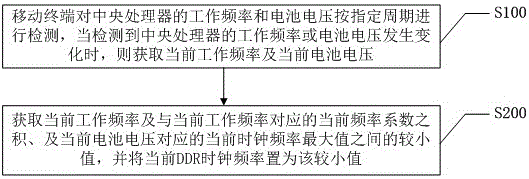

DDR clock frequency control method and system

InactiveCN105116985AAvoid error-prone problemsVolume/mass flow measurementPower supply for data processingClock rateCell voltage

The present invention discloses a DDR clock frequency control method and system. The method comprises: a mobile terminal detecting an operating frequency and a battery voltage of the CPU in a certain period, and obtaining a current operating frequency and a current battery voltage when a change of operating frequency or the battery voltage being detected; obtaining the current operating frequency, a product of a current frequency coefficient corresponding to the current operating frequency, a relatively small value among maximum values of a current clock frequency corresponding to the current battery voltage, and setting a current DDR clock frequency to the relatively small value. The DDR clock frequency of the mobile terminal disclosed by the invention can not only be adjusted according to the operating frequency of the CPU, but also can be dynamically adjusted according to the battery voltage, thereby ensuring the DDR clock frequency to be adjusted to an optimum operating frequency, and avoiding a problem of a liable procedure error in a low battery of the terminal.

Owner:TCL COMM TECH NINGBO CO LTD

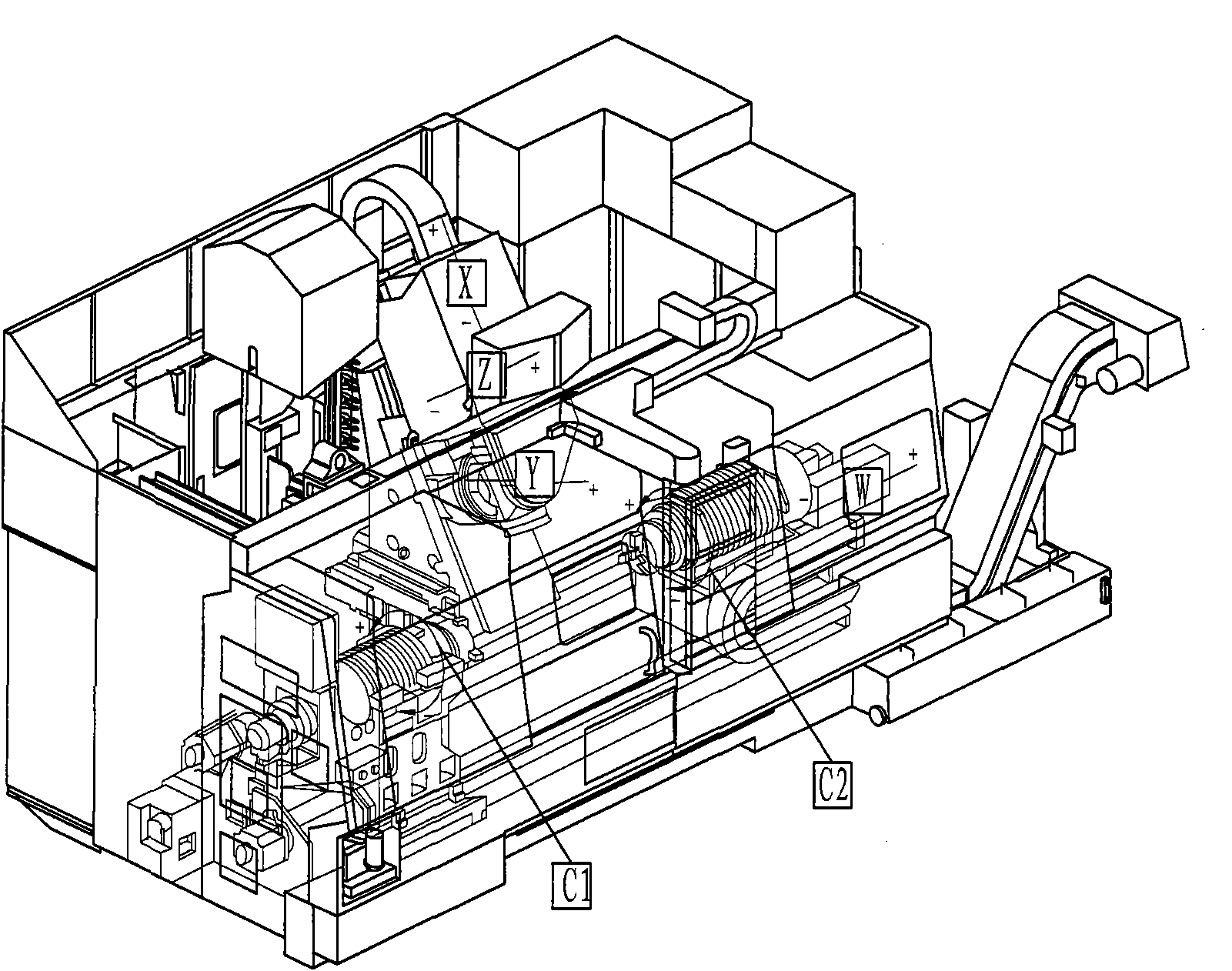

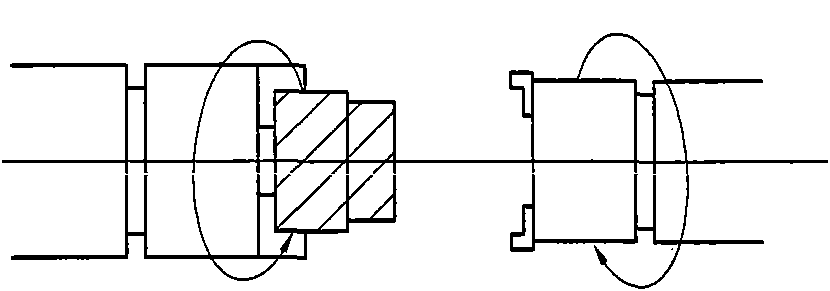

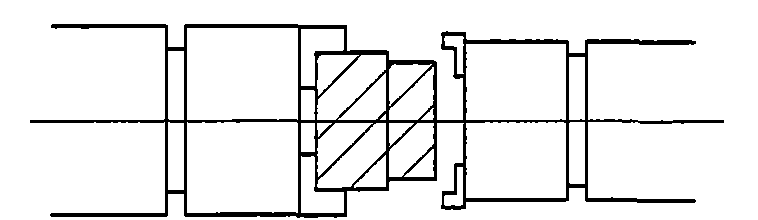

Method for processing machine elements and device thereof

InactiveCN101780640AShorten the production cycleAvoid the influence of human factorsOther manufacturing equipments/toolsPositioning apparatusMechanical componentsEngineering

The invention relates to a method for processing machine elements. The method comprises: processing a workpiece by alternating two clamping components; and keeping the workpiece move along the same straight line during the process of alternating clamping the workpiece by one clamping component into clamping the workpiece by the other clamping component. Fixtures for realizing the method comprise a first chuck and a second chuck, wherein the first chuck rotates along a C shaft, and the second chuck can rotate along a C2 shaft; shaft axis of the C shaft and the C2 shaft are in the same straight line; the C shaft and the C2 shaft rotate at the same speed and along the same direction; and the C2 shaft moves forward and backward along the shaft axes thereof, and a clamping unit is arranged on processing equipment. By utilizing the primary clamping technology, the invention can continuously finish multiple cutting procedures of the machine elements, and all the process segments of element production from a semifinished product to a finished product can be finished by the device provided by the invention, thereby shortening production cycle of products; and simultaneously, primary clamping can also completely avoid the influence of personal factors during the production, and fundamentally overcomes the accumulation of aligning and positioning errors and working procedure errors, thereby remarkably improving the processing accuracy.

Owner:昆山华恒机器人有限公司

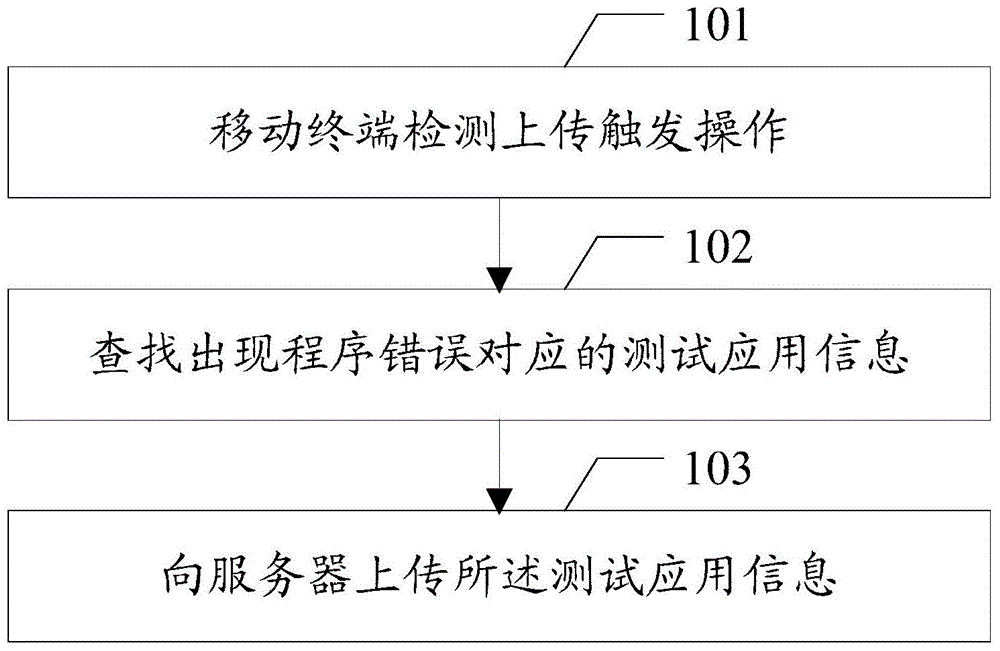

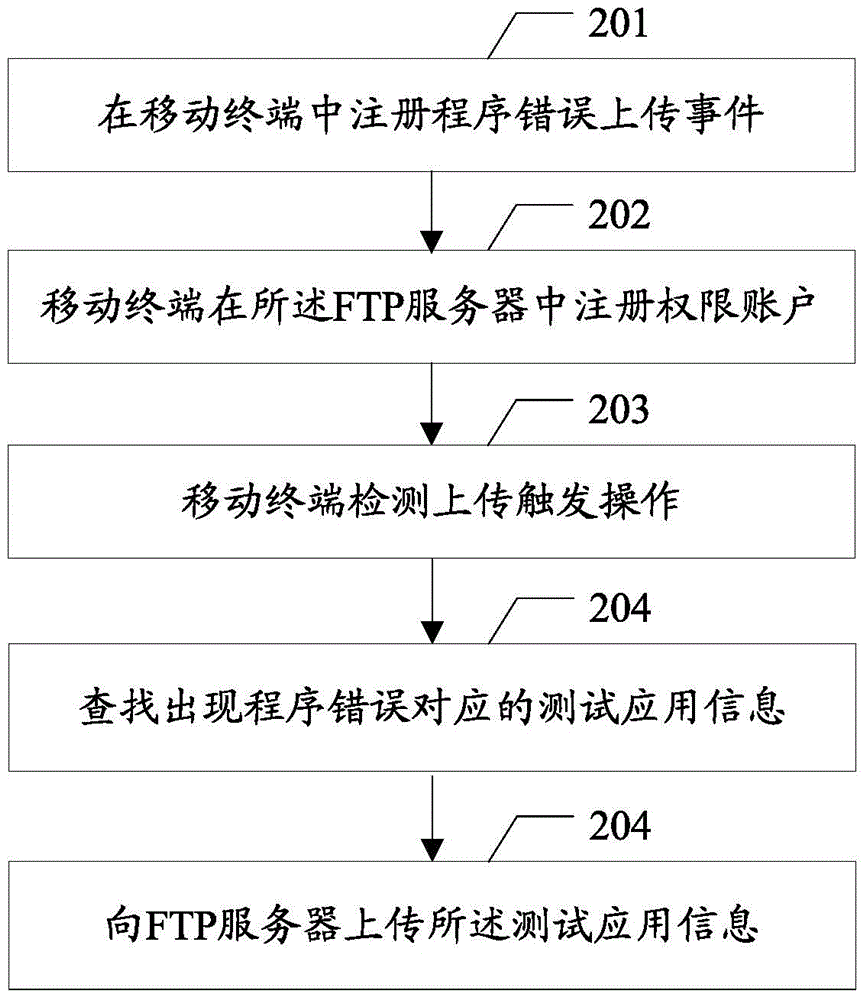

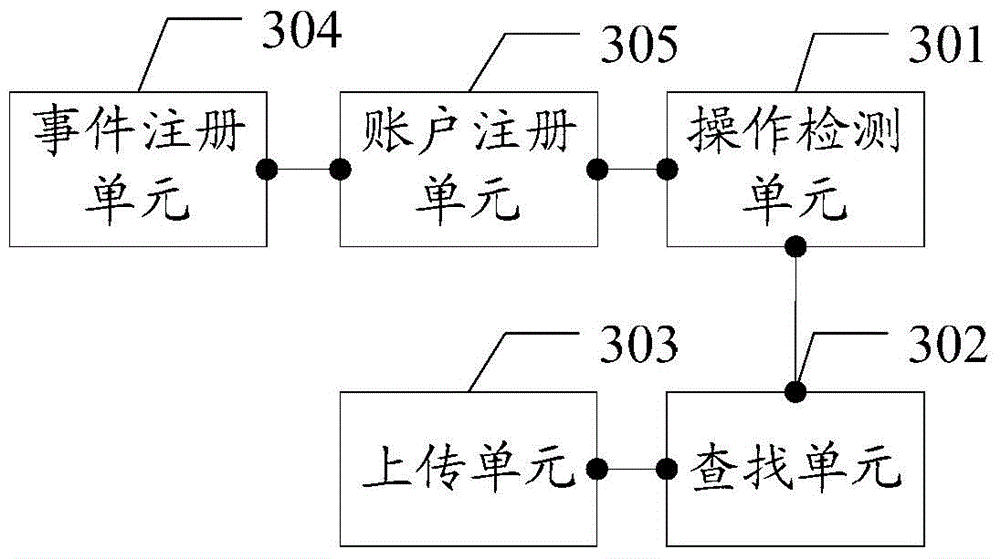

Testing error uploading method and device

ActiveCN105323748AImprove application testing efficiencyEasy to uploadSoftware testing/debuggingNetwork data managementComputer terminalProcedure error

The embodiment of the invention discloses a testing error uploading method and device, and the method and device are used for the convenient and quick uploading of program error information in an application testing program. The method comprises the steps: detecting an uploading triggering operation, which serves as a specific operation for triggering the uploading event of a register program error in a mobile terminal, through the mobile terminal; detecting the testing application information corresponding to a program error if the uploading triggering operation is detected, and uploading the testing application information to the server.

Owner:TENCENT TECH (SHENZHEN) CO LTD

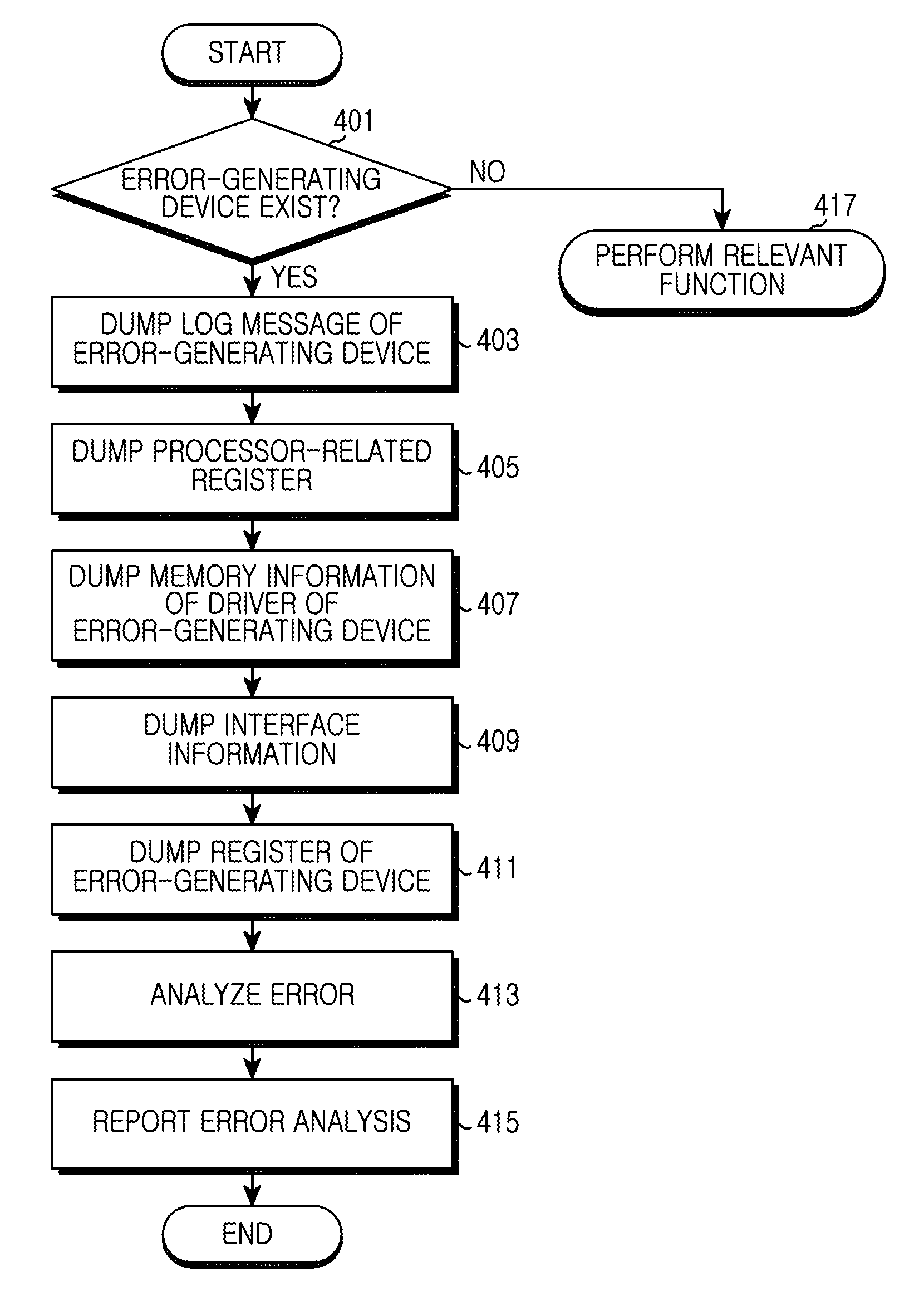

Apparatus and method for analyzing error generation in mobile terminal

Owner:SAMSUNG ELECTRONICS CO LTD

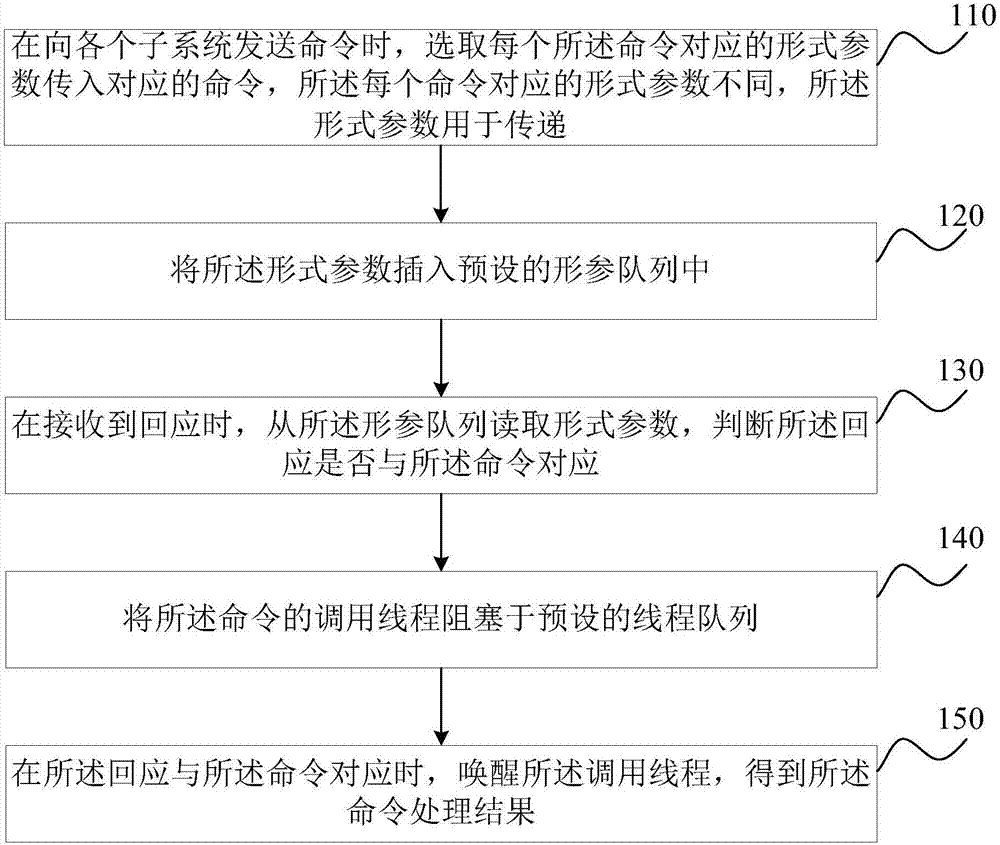

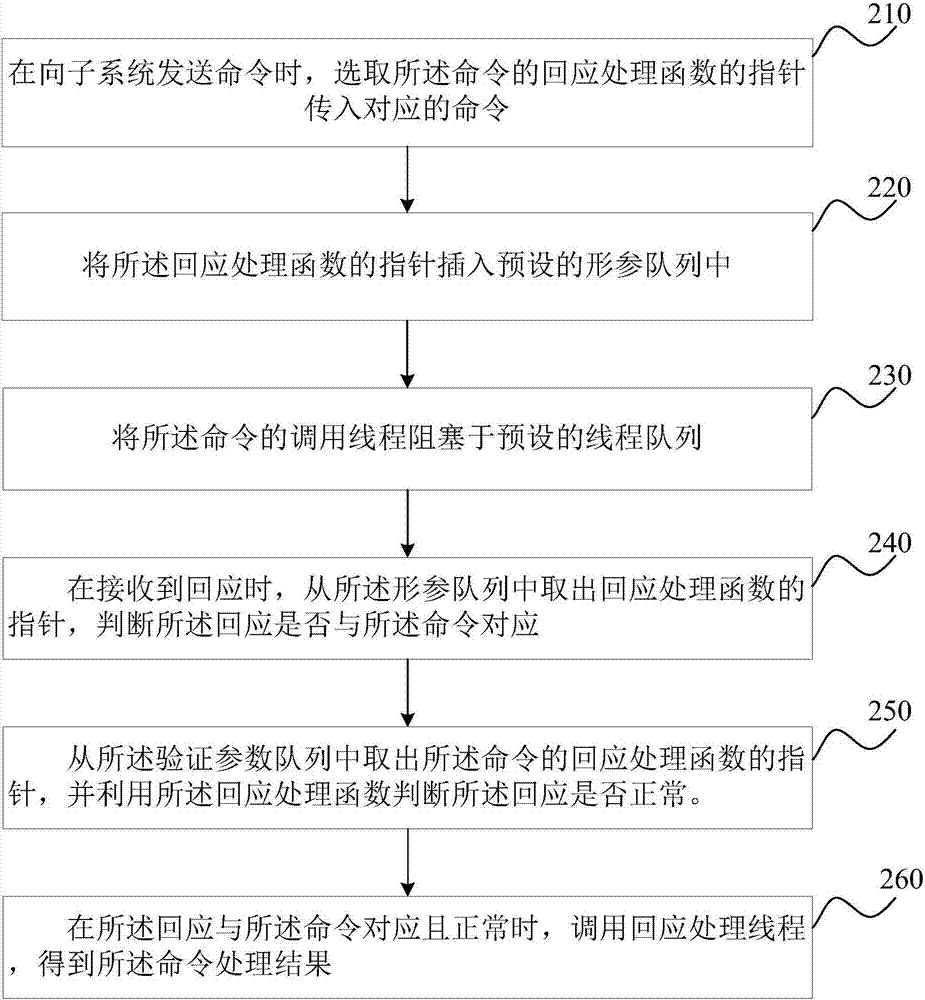

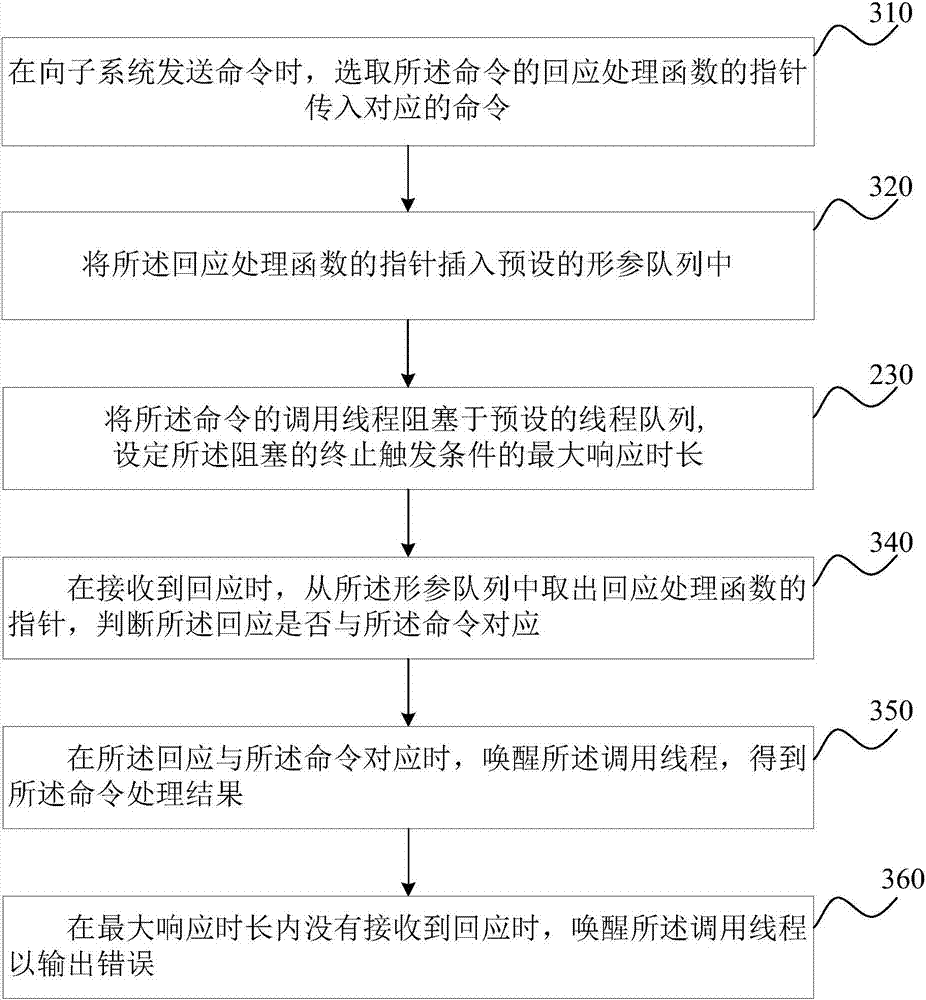

Subsystem command synchronization method and device

ActiveCN107102582AReduce complexityAvoid program errorsProgramme controlComputer controlComputer hardwareMessage queue

The embodiment of the invention discloses a subsystem command synchronization method and device. The method comprises: when commands are sent to a subsystem, selecting formal parameters corresponding to the commands and transmitting the formal parameters corresponding to the commands to corresponding commands, wherein the formal parameters corresponding to each command are different, and the formal parameters are used for transmission; inserting the formal parameters into a preset formal parameter queue; blocking calling threads of the commands at the preset formal parameter queue; when responses are received, reading the formal parameters from the formal parameter queue, and determining whether the responses correspond to the commands; and when the responses correspond to the commands, waking up the calling threads, and obtaining a command processing result. Through adoption of message notification modes, the subsystem command synchronization method and device realize command synchronization of a plurality of subsystems so as to avoid program errors caused by asynchronous mode. Besides, message queue interfaces are only needed to perform package to realize command synchronization so as to realize complexity of the software design.

Owner:SHENZHEN YIHUA COMP +2

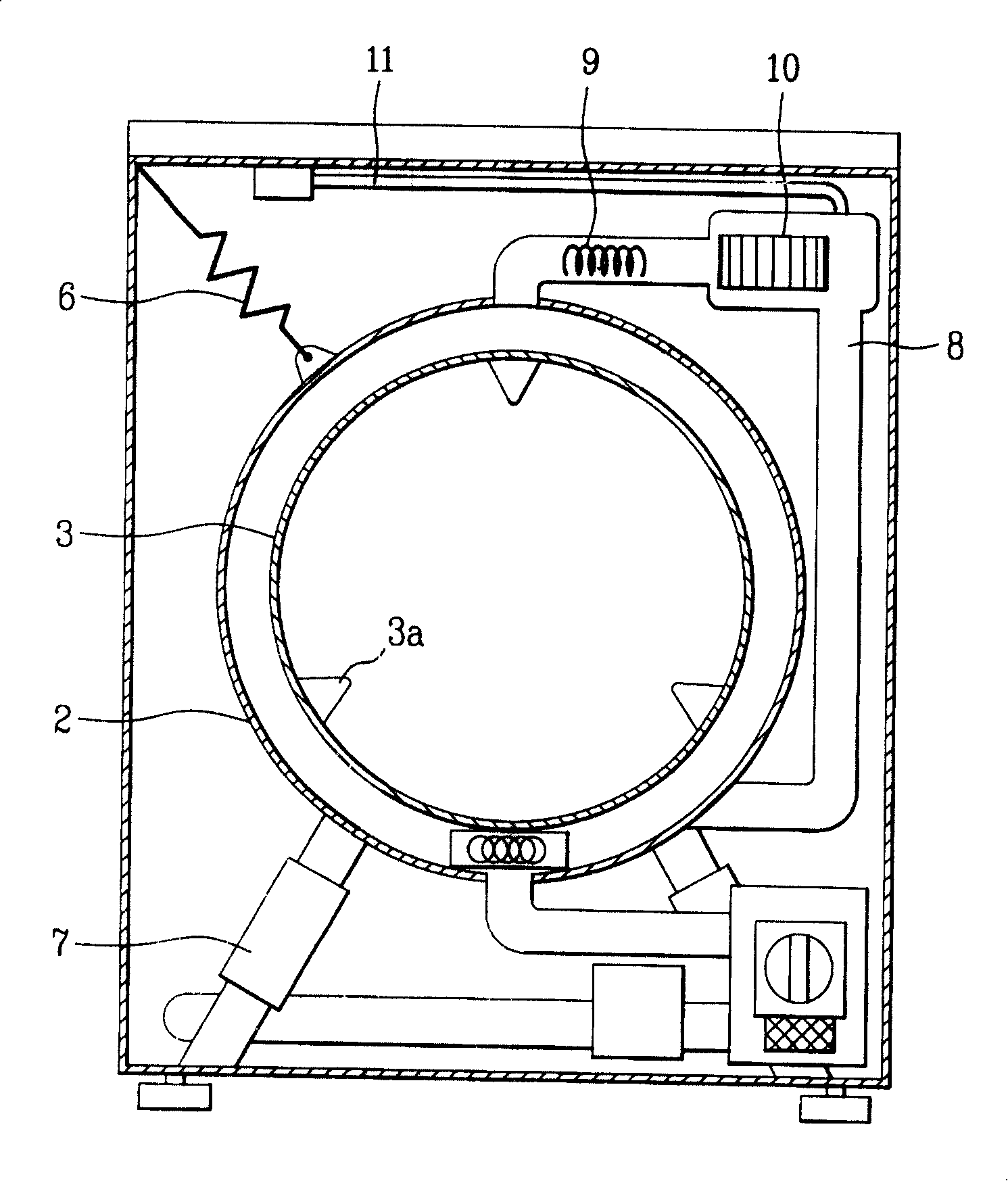

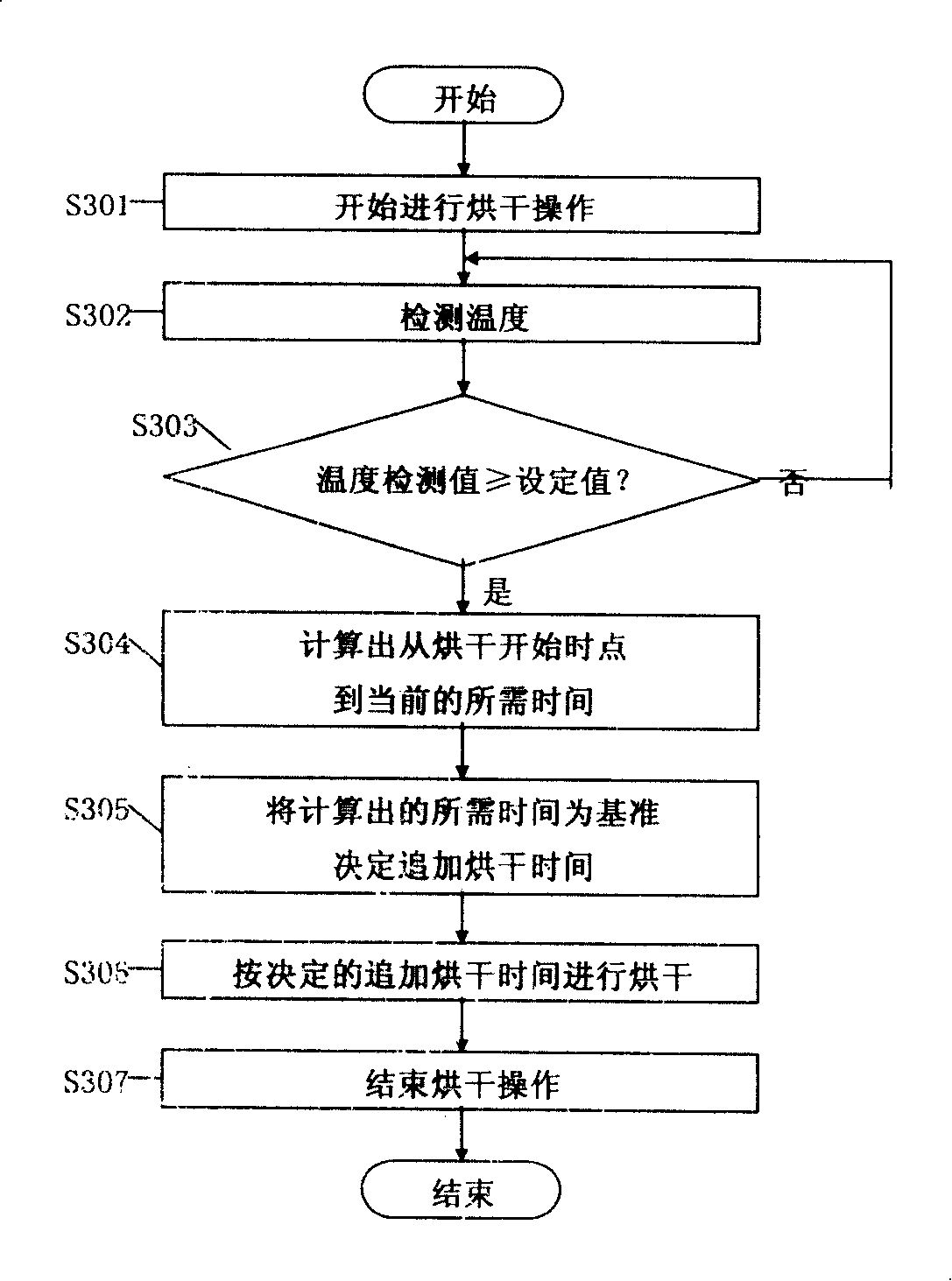

Drying control method for washing machine

InactiveCN101173447AAvoid mistakesControl devices for washing apparatusWashing machine with receptaclesProcess engineeringDrying time

The invention relates to a drying control method for the cloth washing device, which comprises the following steps: inspecting the laundry package to be dried; calculating the time from start of drying to satisfying drying condition, and comparing the inspected laundry package with the set standard laundry package, performing additional drying operation only when the inspected laundry package is more than the standard laundry package; wherein, under the condition that the inspected laundry package is more than the standard laundry package, determining the additional drying time through dividing the time from beginning drying to satisfying drying condition in stages, thereby, performing drying operation according to the additional drying time; then finishing drying process. When the laundry is drying automatically, the additional drying time is determined through dividing the laundry package and the required drying time in stages, thereby, the invention has the advantages of avoiding program mistake and simplifying drying algorithm.

Owner:NANJING LG PANDA APPLIANCES

Method for automatically converting program error codes into error descriptions

InactiveCN105550011AImprove work efficiencyError coding preventionProgram controlMemory systemsDocumentationProcedure error

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +2

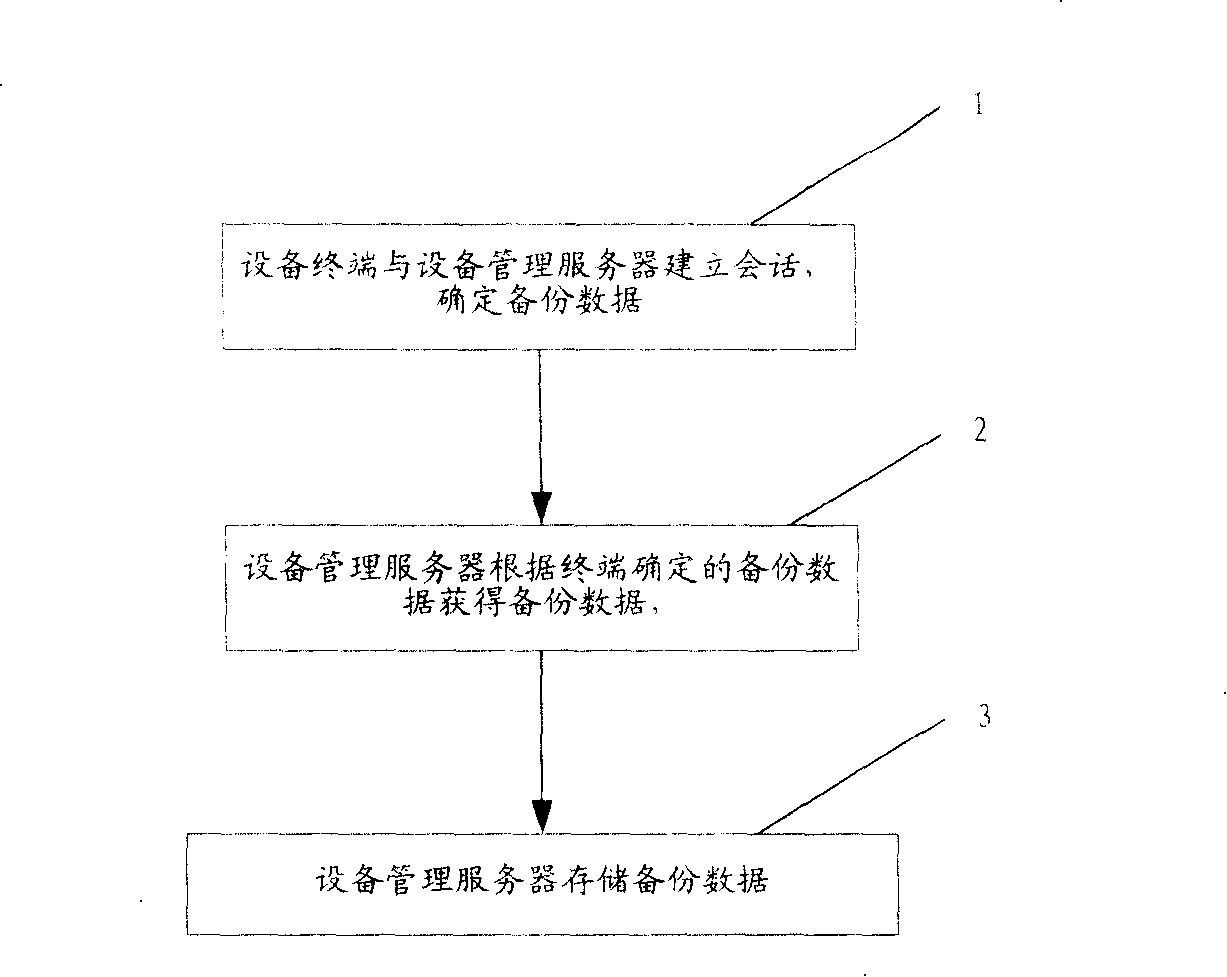

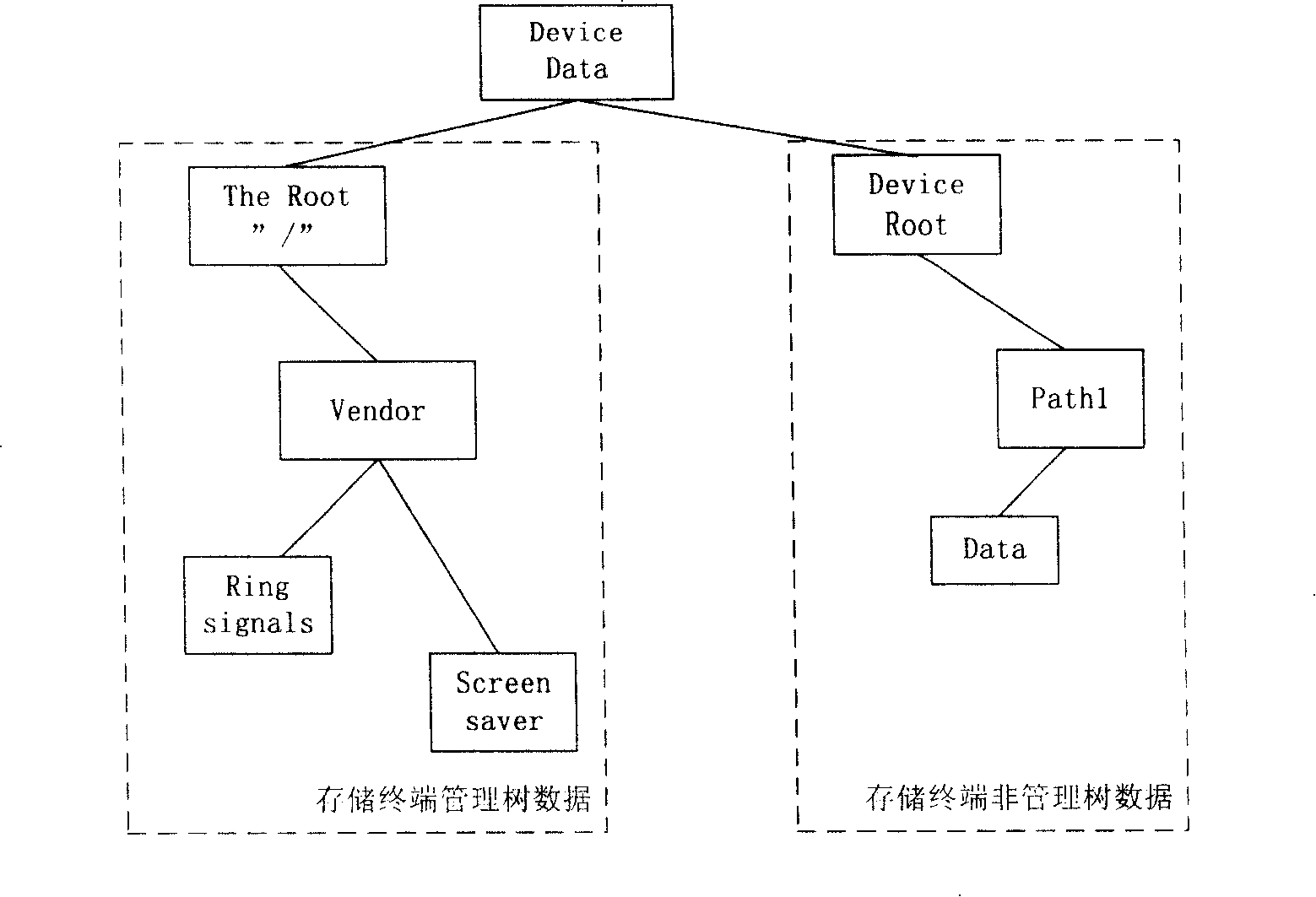

Data backing-up and recovering method and system

ActiveCN100391291CGuaranteed recoverabilityImprove experienceRadio/inductive link selection arrangementsWireless communicationPersonalizationRestoration method

First, the method backs up data of device terminal to device management (DM) server. The said data includes individualization data of software program and device terminal. When data of device terminal are lost or in error, the method can restore the backed data to terminal. When software program at terminal is in error, the method can down load the backed software, as well as installs and configures software in order to recover data and software of device terminal. Storing terminal data in DM server, the invention guarantees recoverability of device terminal data especially private data.

Owner:HUAWEI TECH CO LTD

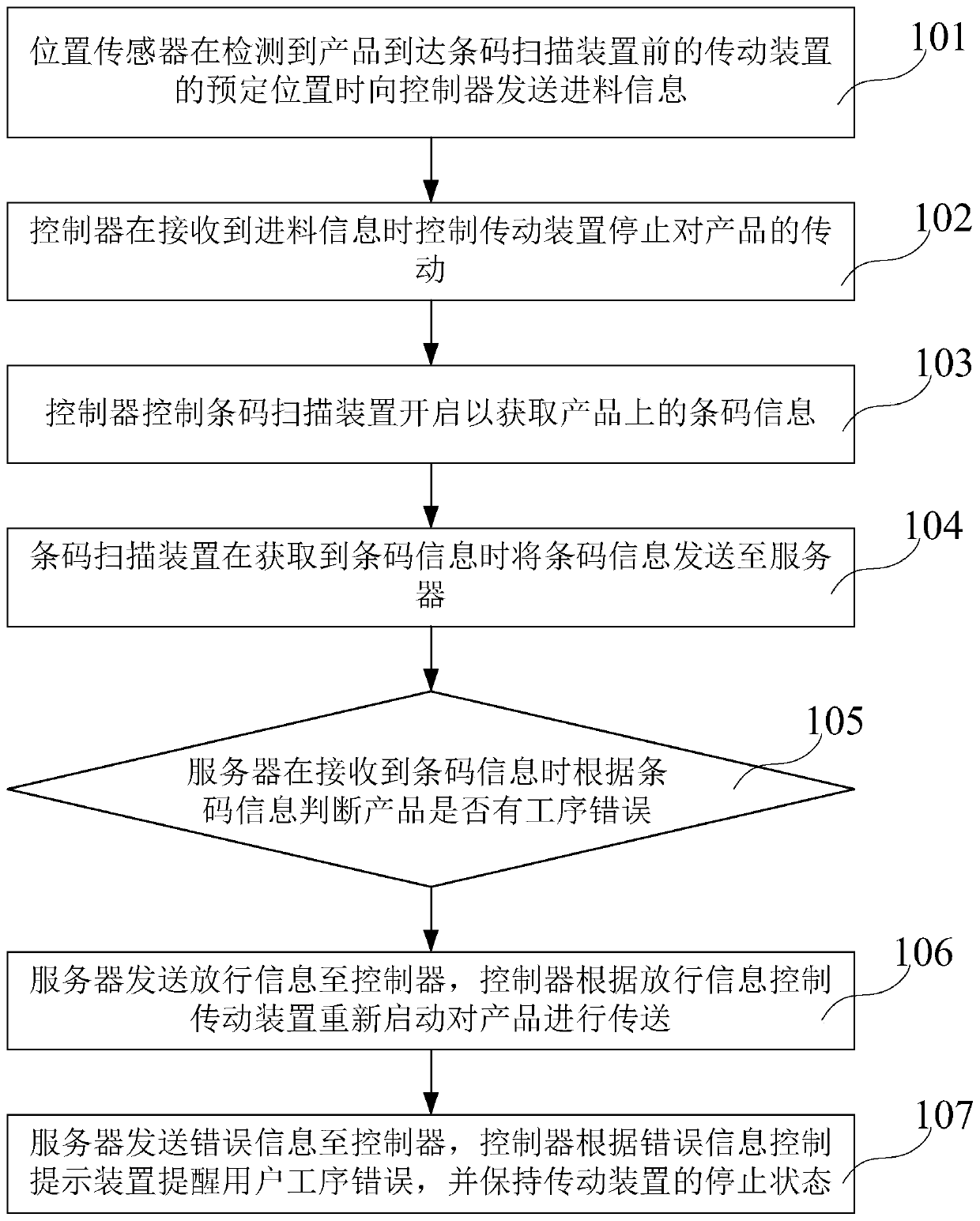

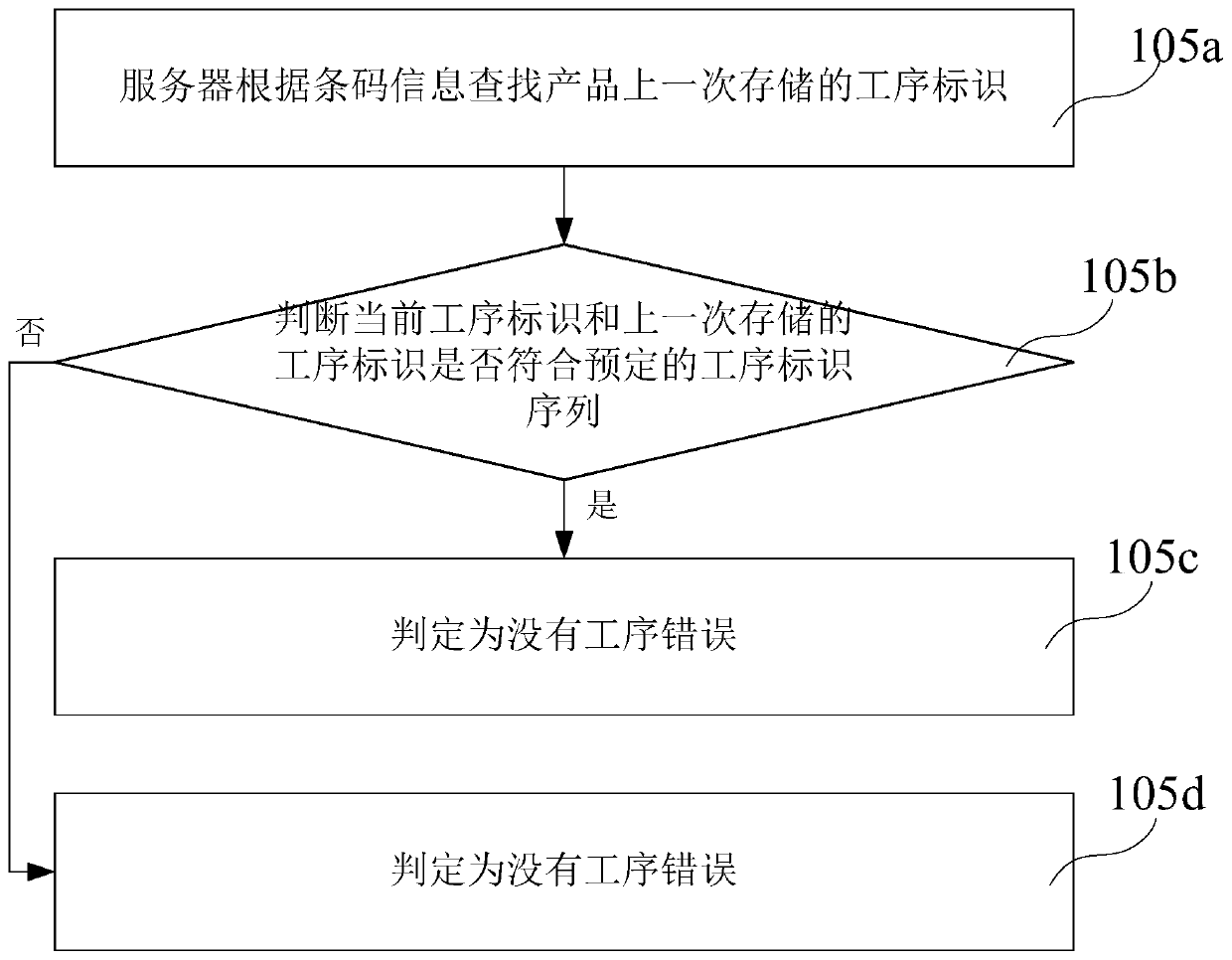

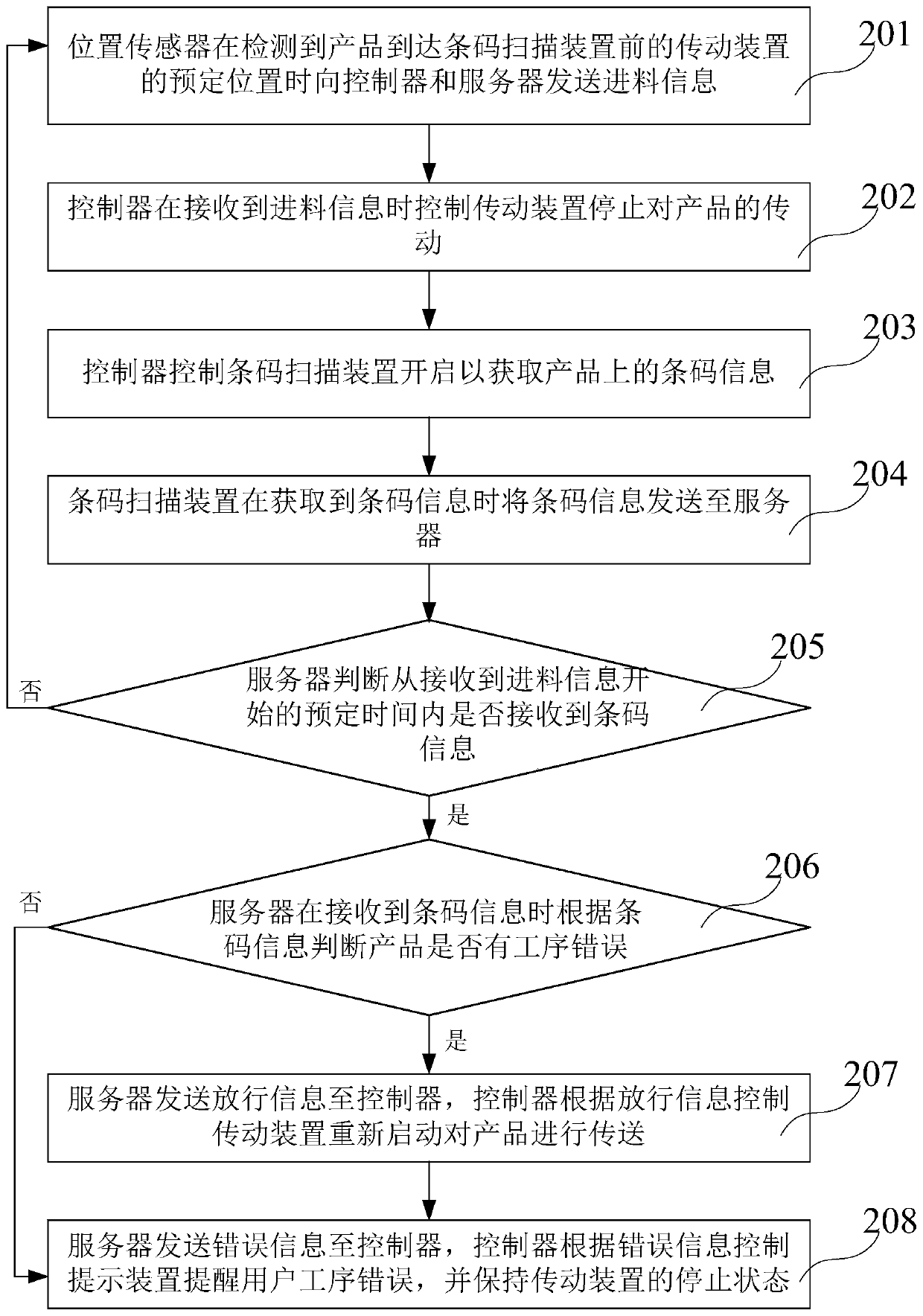

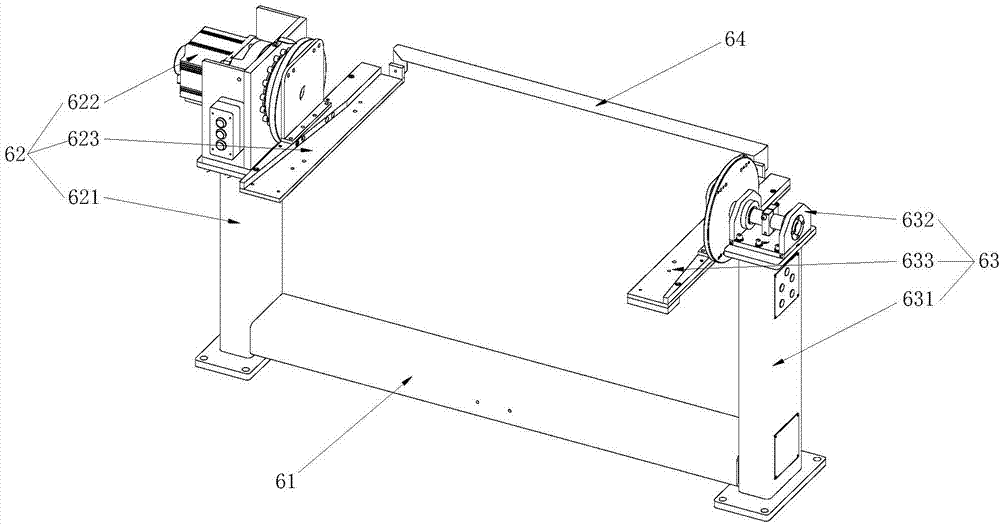

Detection method and detection system for production working procedure, and storage medium

ActiveCN110244674AAutomatic detectionElectric/magnetic position measurementsUsing electrical meansProcedure errorBarcode

The invention discloses a detection method for a production working procedure. The detection method comprises the following steps that: when a position detector detects that a product reaches a transmission device in front of a barcode scanning device, feeding information is sent to a controller; when the controller receives the feeding information, the transmission device is controlled to stop transmitting the product; the controller controls the barcode scanning device to be started to obtain barcode information on the product; when the barcode scanning device obtains the barcode information, the barcode information is sent to a server; and when the server receives the barcode information, according to the barcode information, whether the product has working procedure errors or not can be judged, when the server judges that the product does not have the working procedure errors, releasing information is sent to the controller, and the controller controls the transmission device to be started according to the releasing information to transmit the product. Through the above way, the detection method can realize a purpose of automatically detecting production working procedures.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

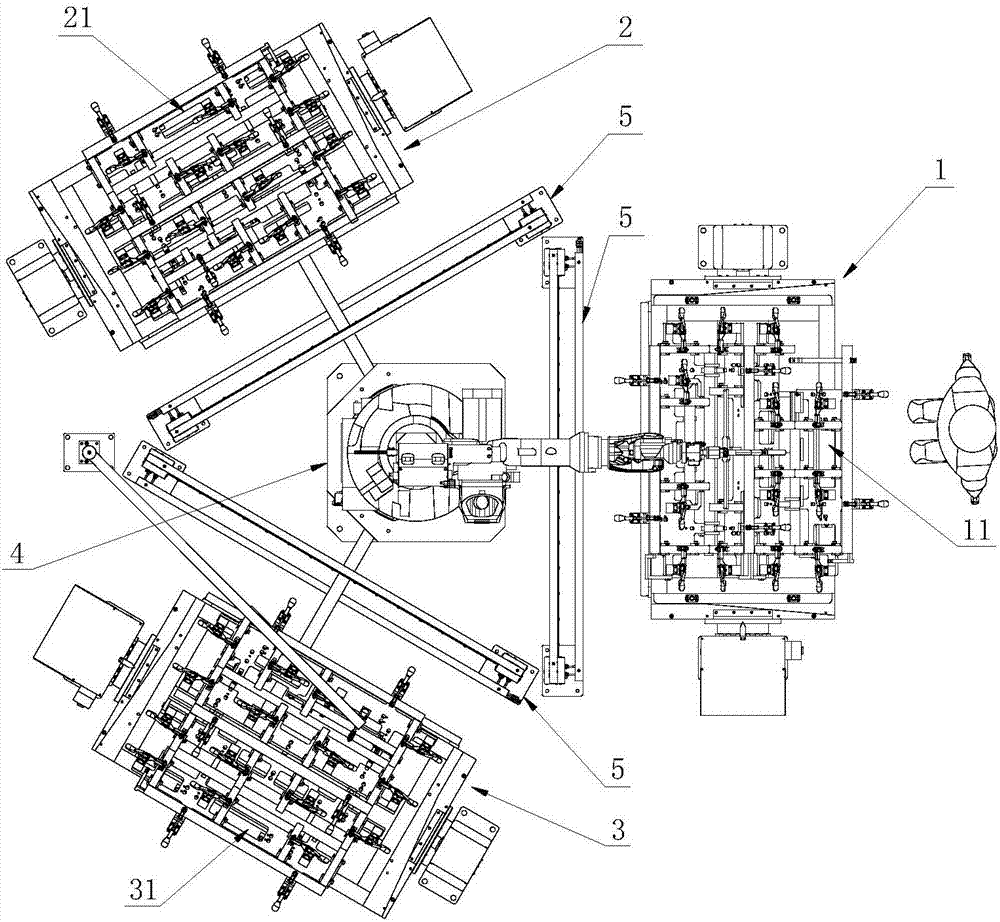

Three-station code scanning automatic welding production line

InactiveCN106975879AReduce labor costsAvoid misuseWelding/cutting auxillary devicesAuxillary welding devicesProduction lineIsoetes triquetra

The invention discloses a three-station code scanning automatic welding production line. The three-station code scanning automatic welding production line comprises a first station, a second station, a third station, a code scanning gun used for identifying bar codes, a six-axis robot used for welding and a controller. The first station, the second station and the third station are distributed in an equilateral triangle shape, and the six-axis robot is located in the center of the equilateral triangle. A first clamp used for fixing a workpiece is arranged on the first station and provided with a first bar code, a second clamp used for fixing the workpiece is arranged on the second station and provided with a second bar code, and a third clamp used for fixing the workpiece is arranged on the third station and provided with a third bar code. According to the three-station code scanning automatic welding production line, the problems that due to frequent switching of robot welding procedures, mistakes are prone to occurring, and efficiency is low are effectively solved, quick and flexible procedure switching in the robot welding process is achieved, labor cost of an enterprise is greatly reduced, the welding quality is ensured, and welding efficiency is improved.

Owner:XIAMEN SHI QI MACHINERY

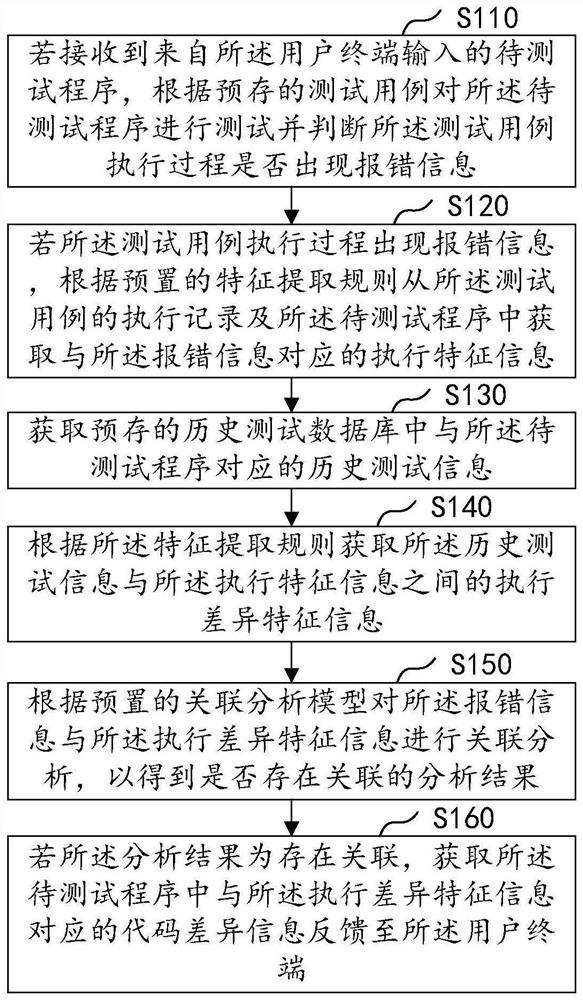

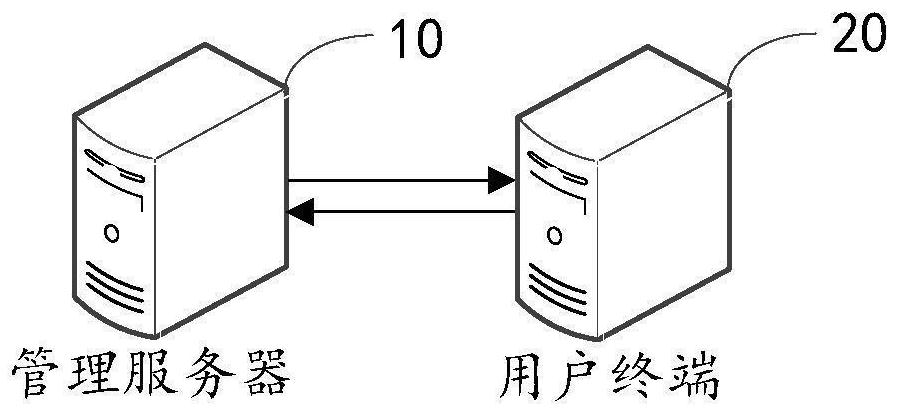

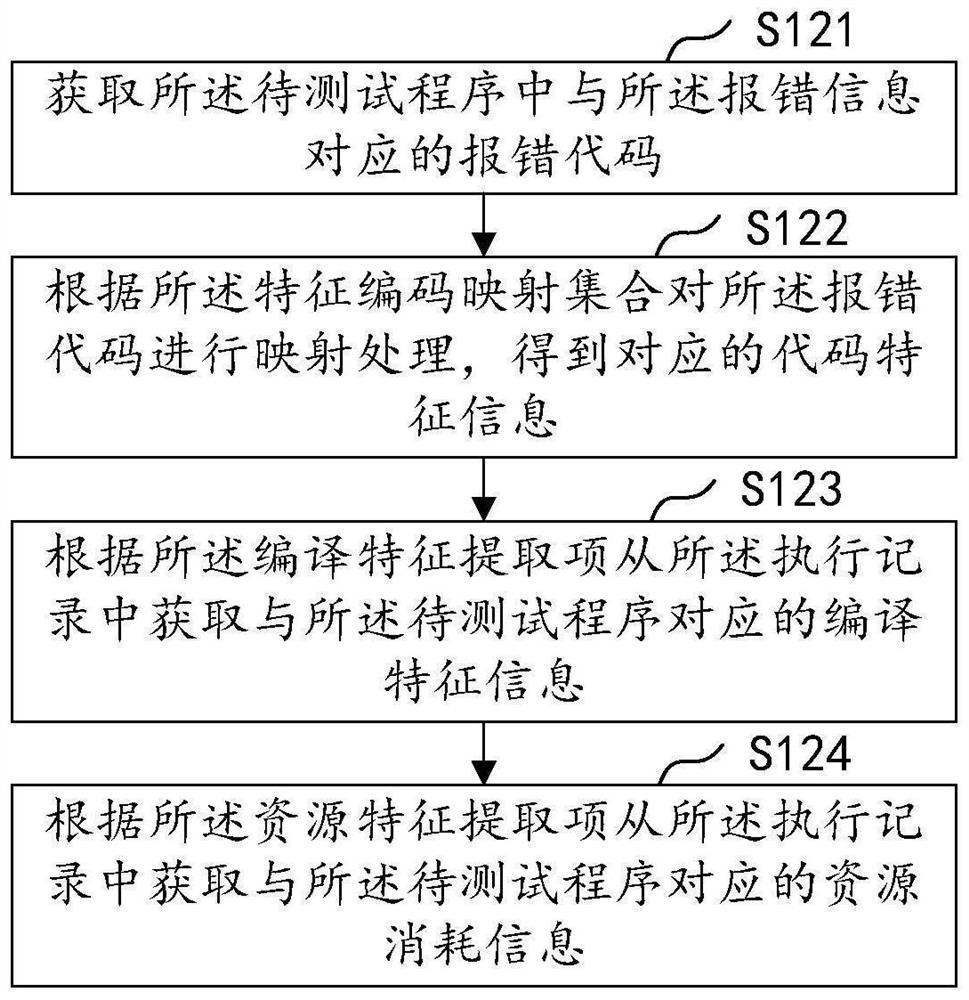

Program error information identification method and device, equipment and medium

The invention discloses a program error information identification method and device, equipment and a medium, and the method comprises the steps: testing a to-be-tested program according to a test case, judging whether error information appears or not, and if the error information appears, obtaining execution feature information from an execution discipline of the test case and a to-be-tested application program, historical test information corresponding to the to-be-tested program is obtained, execution difference feature information between the historical test information and the execution feature information is extracted, correlation analysis is conducted on the error reporting information and the execution difference feature information according to a correlation analysis model, and if correlation exists, code difference information corresponding to the execution difference feature information is obtained and fed back to the user terminal. The method belongs to the technical field of intelligent decision making, the error information and the execution difference feature information can be subjected to correlation analysis to obtain whether correlation exists between code differences of the error information or not, the program error information can be rapidly recognized, and therefore the specific position of a program code causing the error information is rapidly determined.

Owner:WEIKUN (SHANGHAI) TECH SERVICE CO LTD

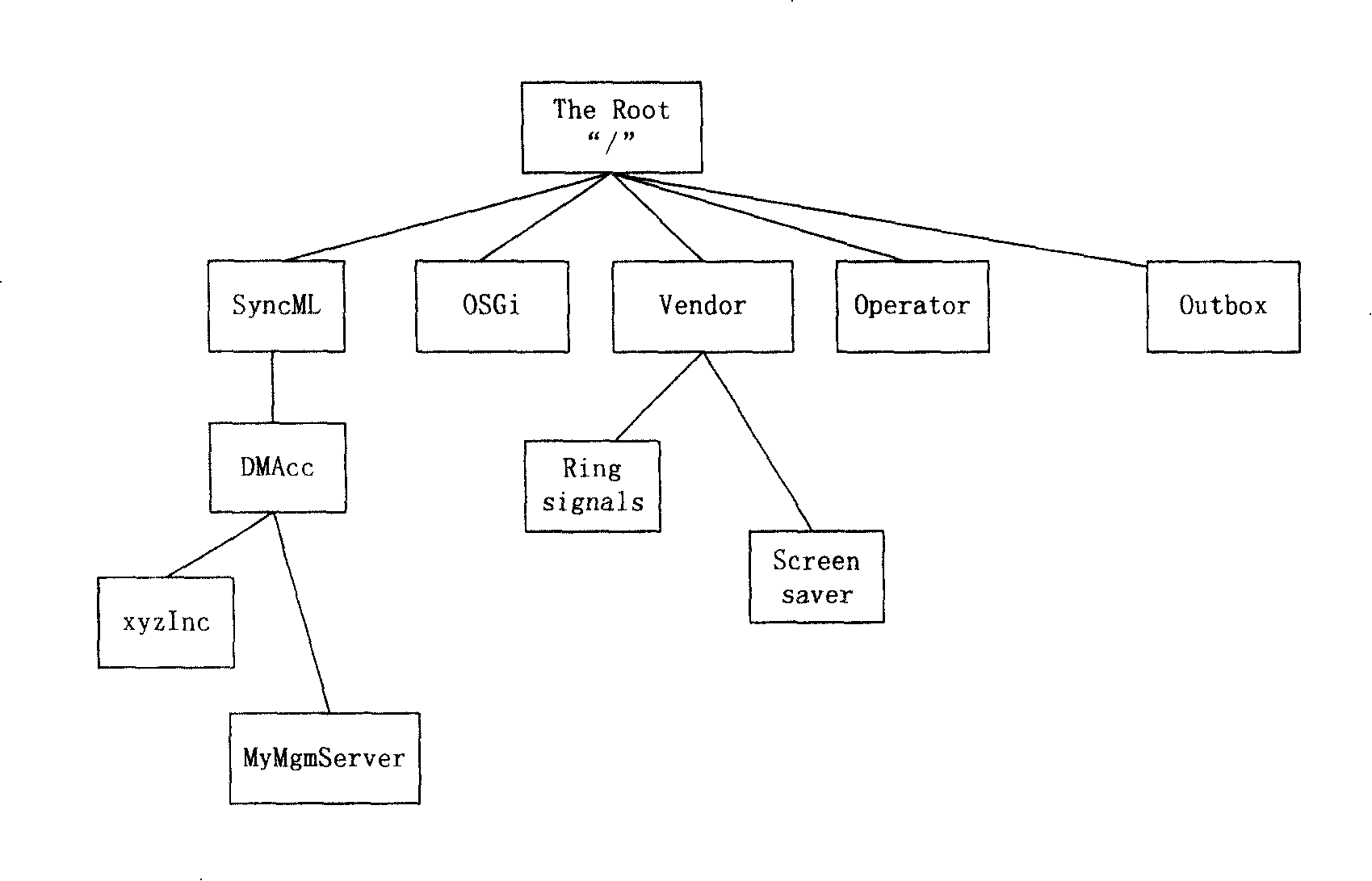

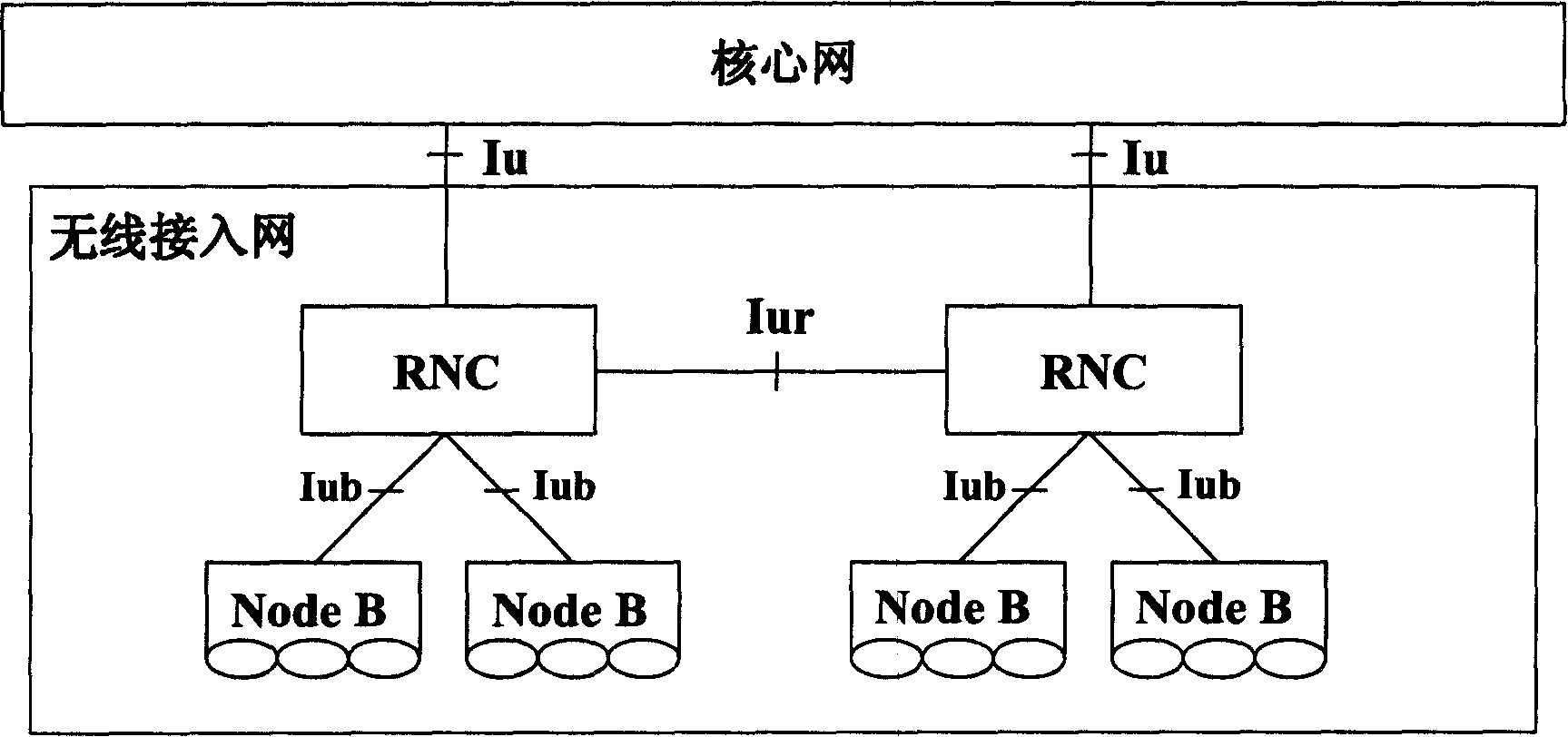

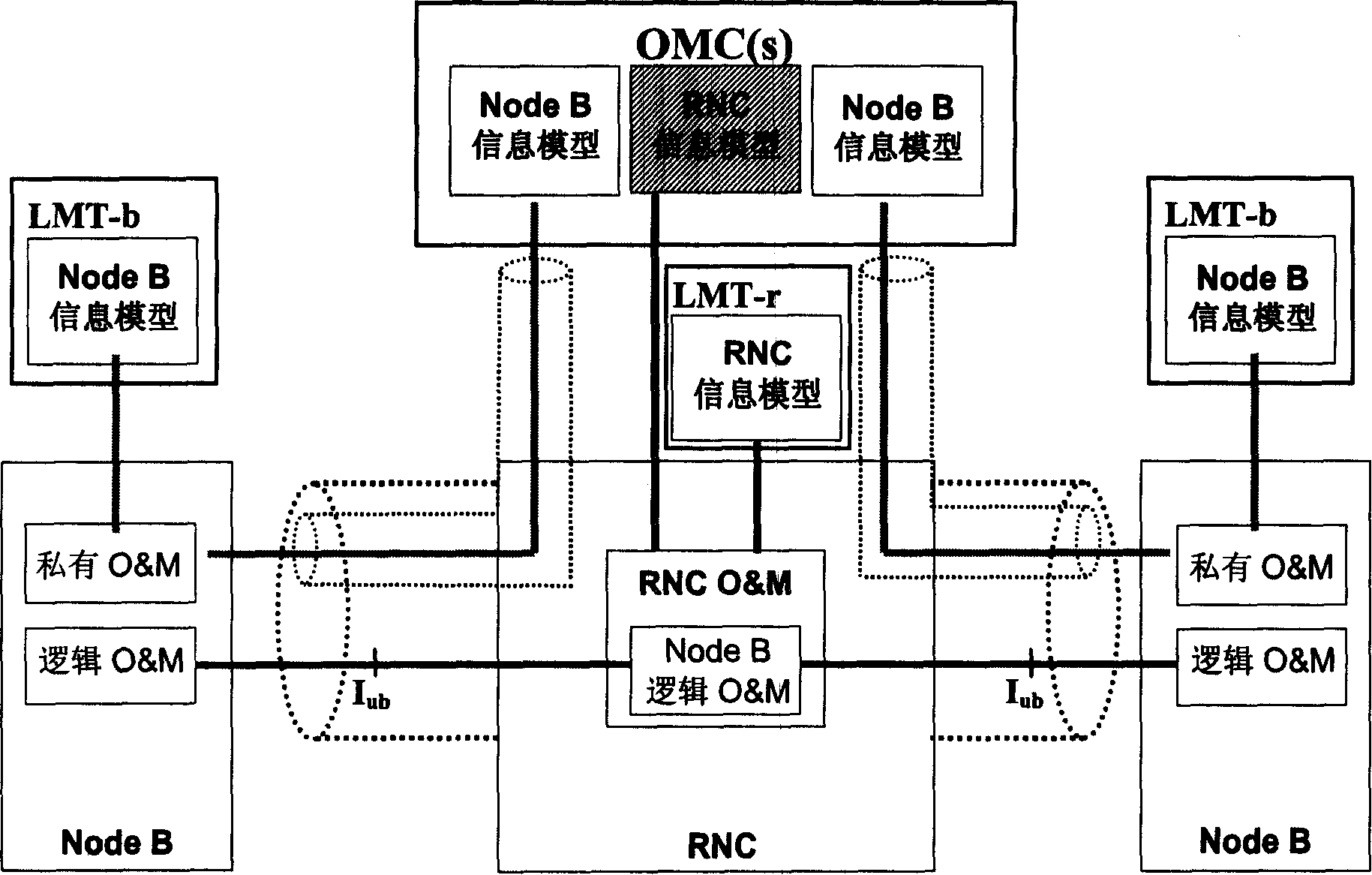

Method for proxy and manager sharing information model in telecommunication management network

InactiveCN1829214ASimplify the sharing processReduce error rateData switching networksManaged objectExtensible markup

The present invention refers to succedaneum and supervisor sharing information method in telecommunication administrative net telecommunication. Said succedaneum and supervisor use both sides promissory standard format to proceed information model sharing in information model sharing process. Said standard format is determined in establishing management linked initial handshake process in succedaneum and supervisor, adopting succedaneum and supervisor both sides acquiescent standard format. Said succedaneum and supervisor promissory standard format can use tables form, or extensible marking language or abstract syntax notation 1 etc mode, describing managed object congregation, each management interface, and correlation among managed object, said succedaneum and supervisor capable of according to said standard tables or extensible marking language description, utilizing computer program automatic generation said management information tree, not only capable of reducing said information model shared procedure error ratio, but also simplifying said information model shared procedure.

Owner:诺基亚西门子通信系统技术(北京)有限公司

Memory storage device, its memory controller, and data writing method

ActiveCN103186470BIncrease write speedEfficient use of transmission bandwidthMemory adressing/allocation/relocationMemory controllerProcedure error

Owner:PHISON ELECTRONICS

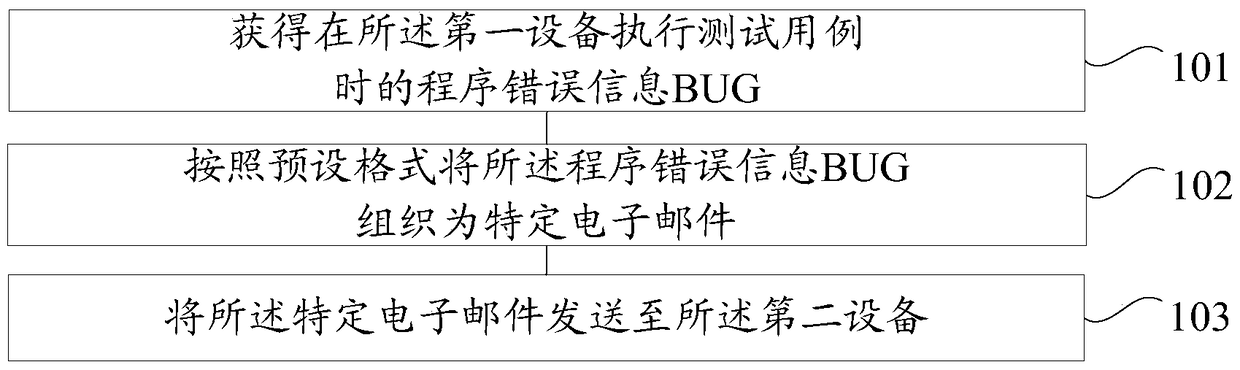

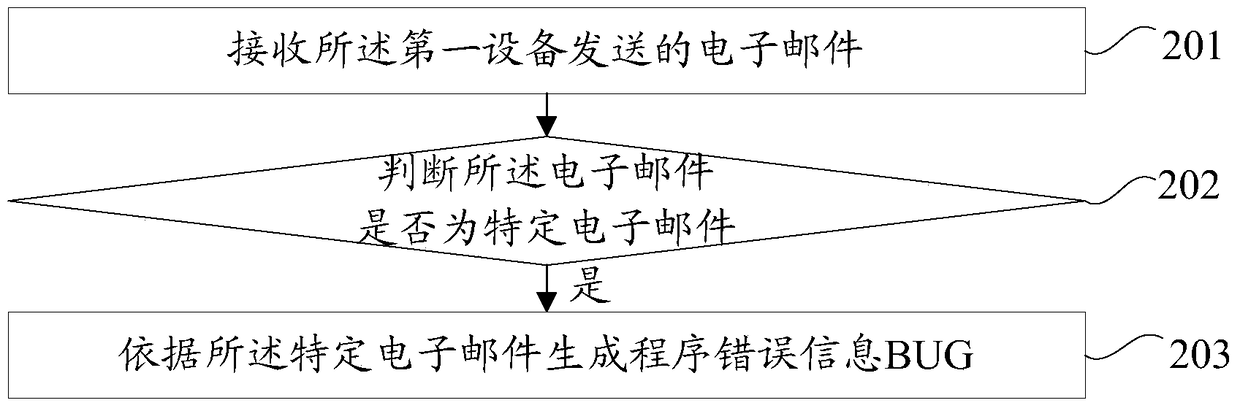

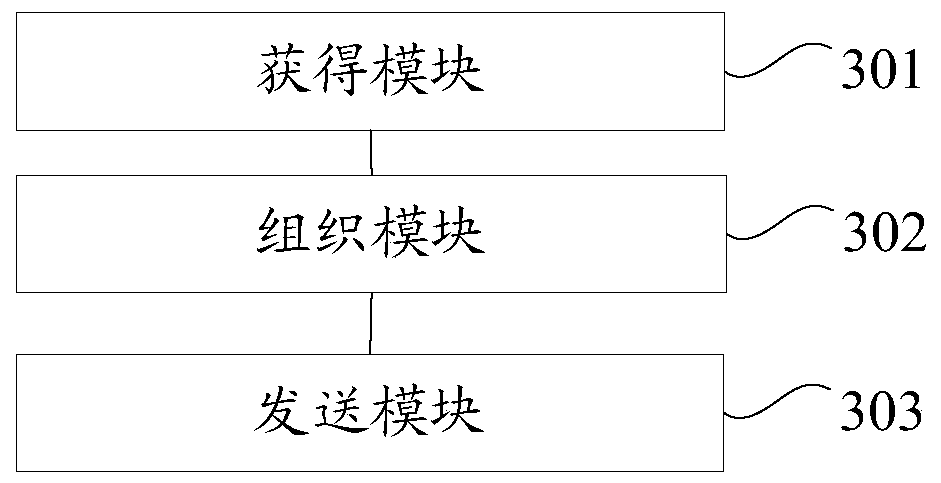

Method and device for program error information bug transmission and reception between local area networks

ActiveCN105337752BImprove transfer efficiencyEasy to implementNetworks interconnectionElectronic mailProcedure error

Embodiments of the invention provide a method and an apparatus for transmitting and receiving program error information BUG between local area networks. The local area networks comprise a first local area network and a second local area network, which are isolated from an external network, the first local area network comprises a first device, the first device has the authority of sending an E-mail to the external network, the second local area network comprises a second device, the second device has the authority of receiving the E-mail of the external network, and the method comprises the following steps: obtaining program error information BUG of the first device when executing a test case; organizing the program error information BUG to a specified E-mail according to a preset format; and sending the specified E-mail to the second device. The method provided by the invention is used for transmitting the program error information BUG between different local area networks and improving the transmission efficiency of the program error information BUG.

Owner:BEIJING AMAZGAME AGE INTERNET TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com