Method for desalting bitter by electromembrane method and equipment thereof

A brackish water desalination and brackish water technology, applied in chemical instruments and methods, water/sewage treatment, general water supply saving, etc., can solve the problems of environmental pollution, high desalination cost, long pretreatment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

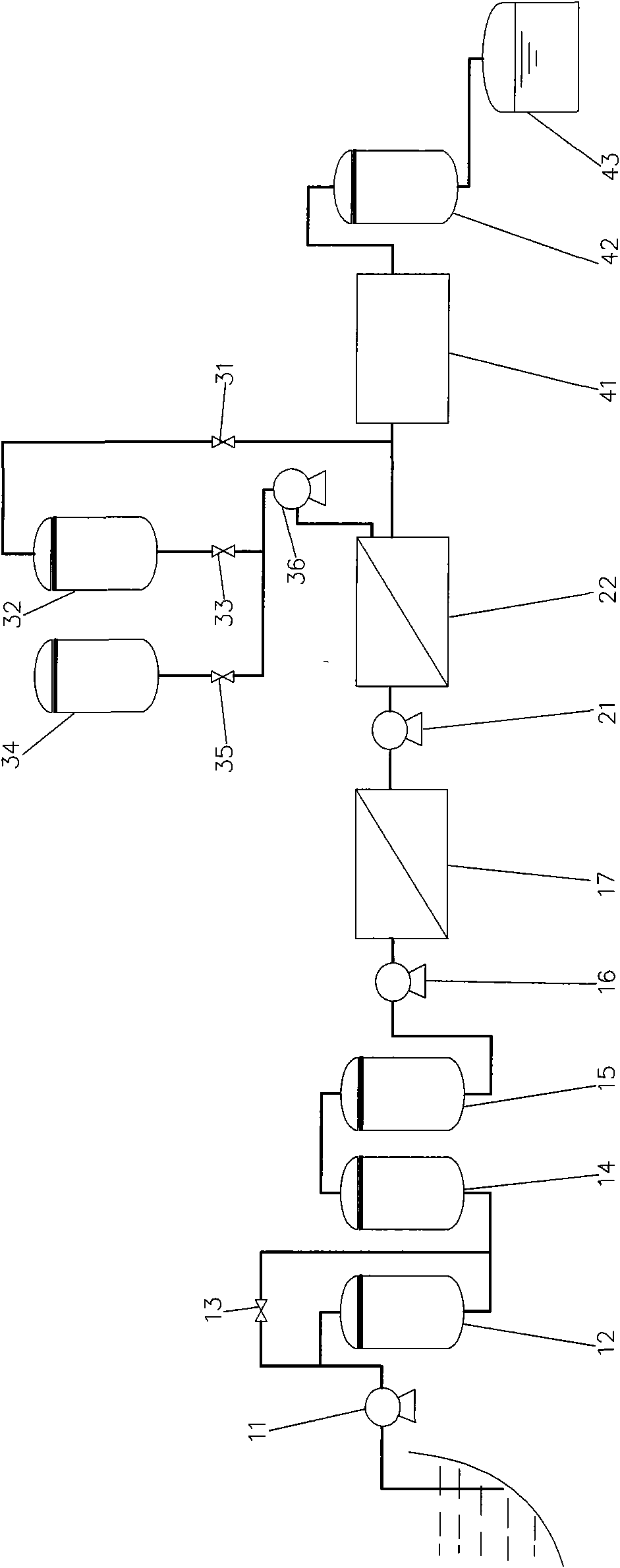

[0032] Such as figure 1 As shown, the electromembrane brackish water desalination method and its equipment of the present invention are composed of brackish water pretreatment system, reverse osmosis desalination system and membrane cleaning and regeneration system.

[0033] The bitter water pretreatment system includes: water intake pump (11), micro electric tank (12), brackish water replenishment valve (13), neutralization tank (14), sand filter tank (15), activated carbon filter tank ( 16), microfiltration system (17). The current input ends of the micro electrolytic tank (12) and the microfiltration system (17) are connected with the output ends of the power supply system. The operating voltage of the micro electrolytic tank (12) is 36V, and the current is 10A. The membrane tube of the microfiltration system (17) is a ceramic membrane with a pore diameter of 0.05-0.1 μm, and the structure is a tubular membrane module. The brackish water is transported to the micro-elect...

specific Embodiment 2

[0038] Such as figure 1 As shown, the electric membrane brackish water desalination method and the complete set of equipment of the present invention are composed of three systems: brackish water pretreatment system, brackish water reverse osmosis desalination system and membrane cleaning and regeneration.

[0039] The brackish water pretreatment system comprises: a water intake pump (11), a micro electric tank (12), a water replenishment valve (13), a neutralization tank (14), a sand filter tank (15), an activated carbon filter tank (16 ), microfiltration system (17). The current input ends of the micro electrolytic tank (12) and the microfiltration system (17) are connected with the output ends of the power supply system. The operating voltage of the micro electrolytic tank (12) is 24V, and the current is 15A. The membrane material of the microfiltration system (17) is an organic membrane with a molecular weight cut-off of more than 250,000 Daltons, and the membrane module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com