Novel fiber grating pressure transducer

A pressure sensor and fiber grating technology, applied in the field of fiber grating pressure sensors, can solve the problems of fiber grating pressure and temperature cross-sensitivity, and achieve the effects of low signal transmission loss, good safety, and avoiding the problem of measurement signal cross-sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

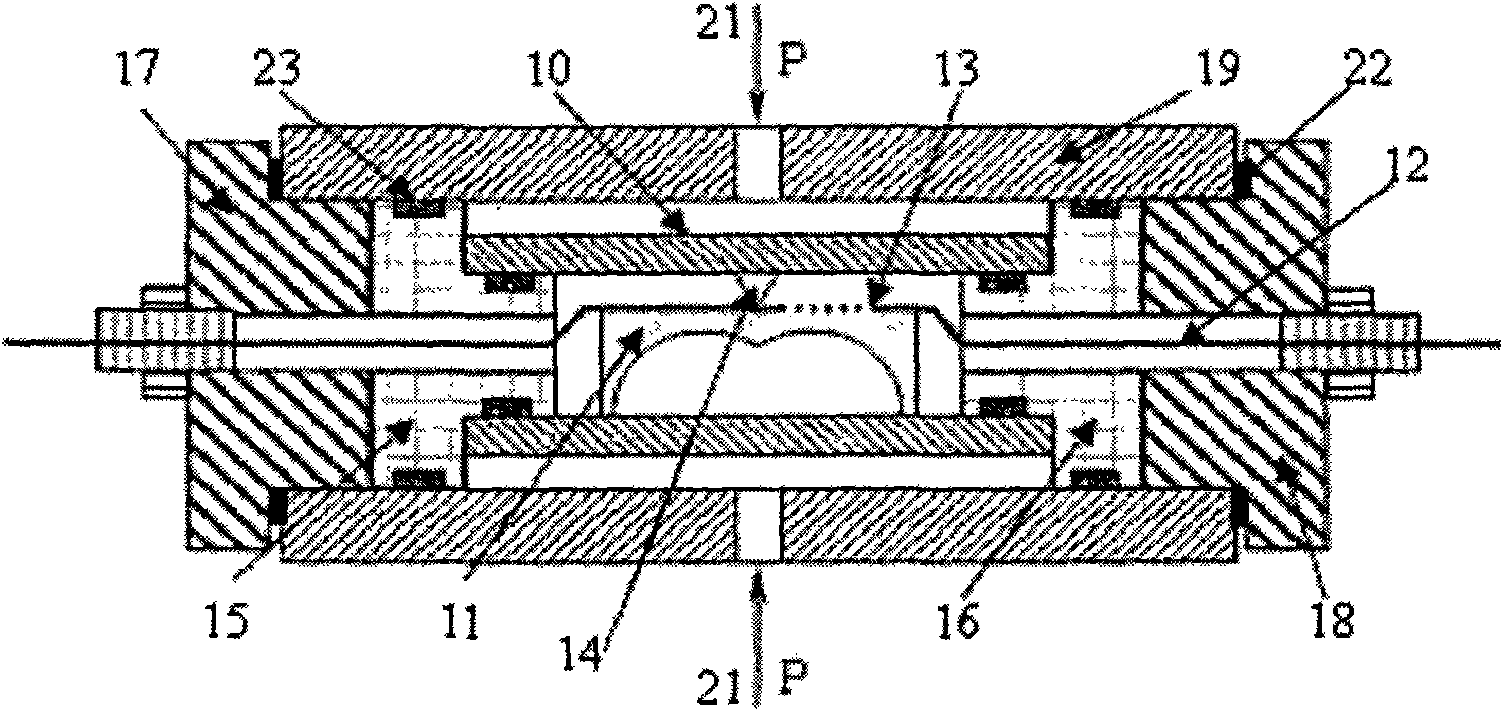

[0020] The fiber grating pressure sensor structure and its measurement principle proposed by the present invention are described as follows in conjunction with the accompanying drawings:

[0021] figure 1 A schematic diagram of the sensor structure. The free elastic cylinder 10 that directly feels the external pressure is "actively" fixed inside the outer protective shell 19 through two end elements 15 and 16 of the same structure and threaded closure elements 17 and 18, and the end elements are connected with the elastic cylinder, The end face element and the outer casing are closely connected by a gasket 22 and an annular sealing ring 23. The cantilever beam 11 is placed inside the free elastic cylinder and maintains permanent "active" contact with it through the contact point 14, engraved on the optical fiber The fiber grating 13 on 12 is fixed on the position between the center of the upper surface of the cantilever beam and the right end, and is connected with the extern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com