Laser probe micro-area component analyzer based on double laser light source

A laser probe and component analysis technology, which is applied in material excitation analysis, instrumentation, optics, etc., can solve problems affecting the selectivity and reliability of element detection, detection error, and pulse laser inability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

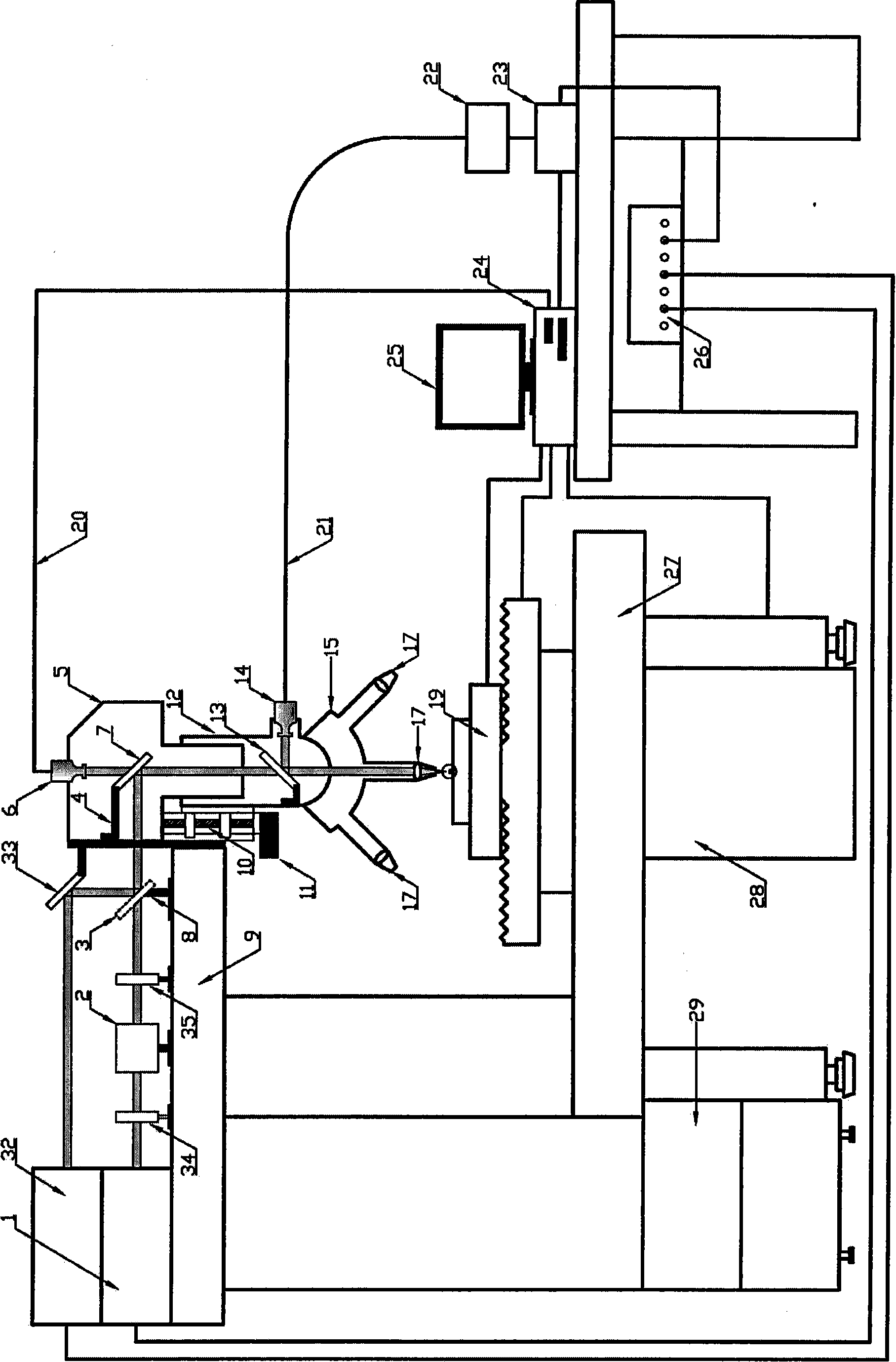

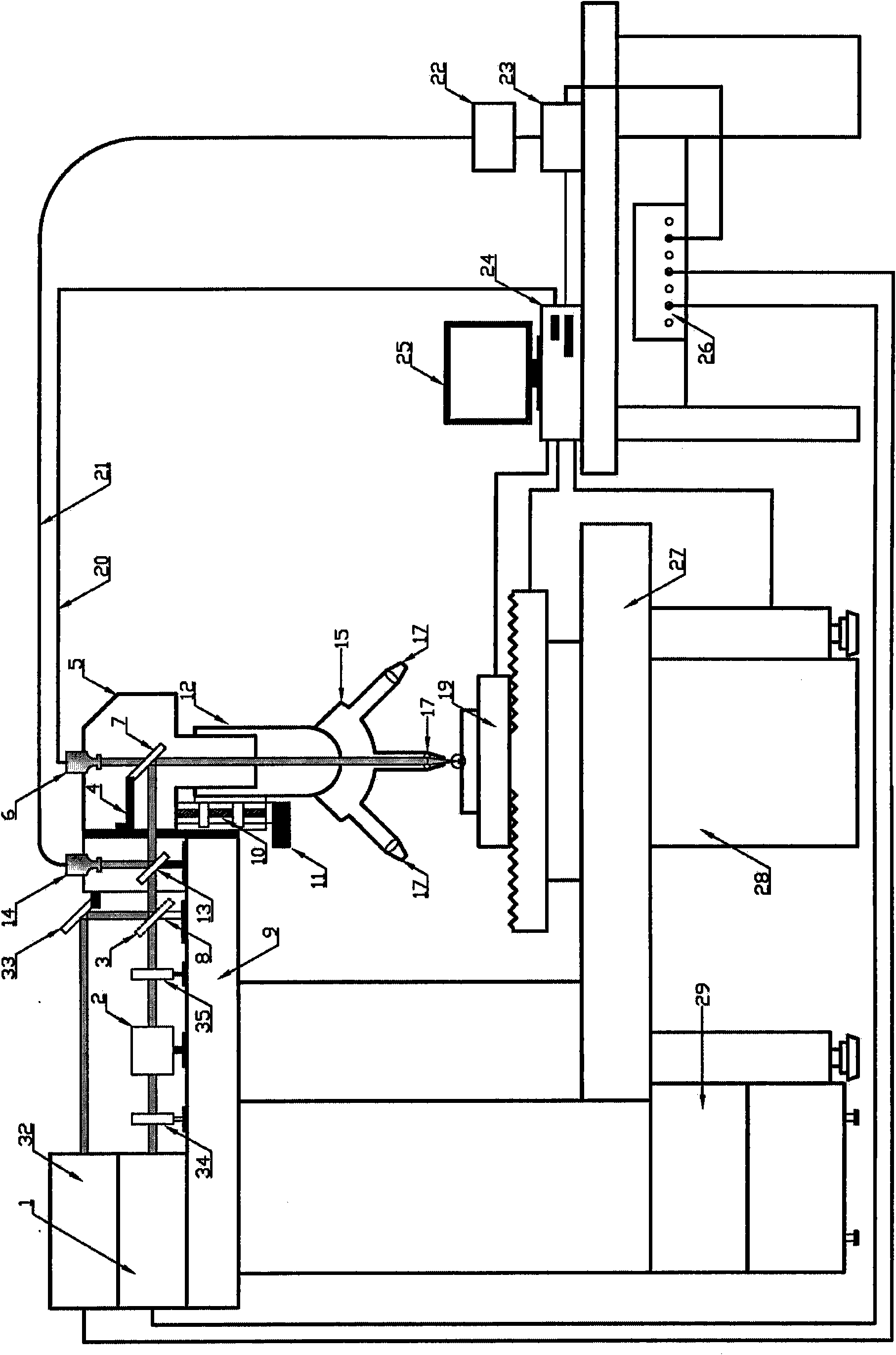

[0027] Such as figure 1 , 2 Shown, the structure of laser probe micro-area component analyzer of the present invention is:

[0028] The light outlet of the fixed-wavelength laser 1, the attenuator 34, the beam expander 2, the aperture stop 35, and the first half-mirror 3 are successively located on the same horizontal optical path, and the transmission surface of the first half-mirror 3 and the The included angle of the substrate 9 is 45 degrees, and also forms an angle of 45 degrees with the horizontal optical path. The total reflection mirror 7 is movably installed, and is parallel to the first half mirror 3 when it is located on the optical path. The second half mirror 13 and the focusing objective lens 17 are sequentially located on the reflection optical path of the first total reflection mirror 7 .

[0029] The wavelength tunable laser 32 is located above the fixed-wavelength laser 1 , and a second total reflection mirror 33 is placed on its outgoing optical path, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com