SMD power inductor and manufacturing method thereof

A power inductor, chip technology, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, inductor with magnetic core, etc., can solve the problems of poor electrical performance and low manufacturing efficiency , to improve production efficiency, ensure consistency, and reduce the number of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

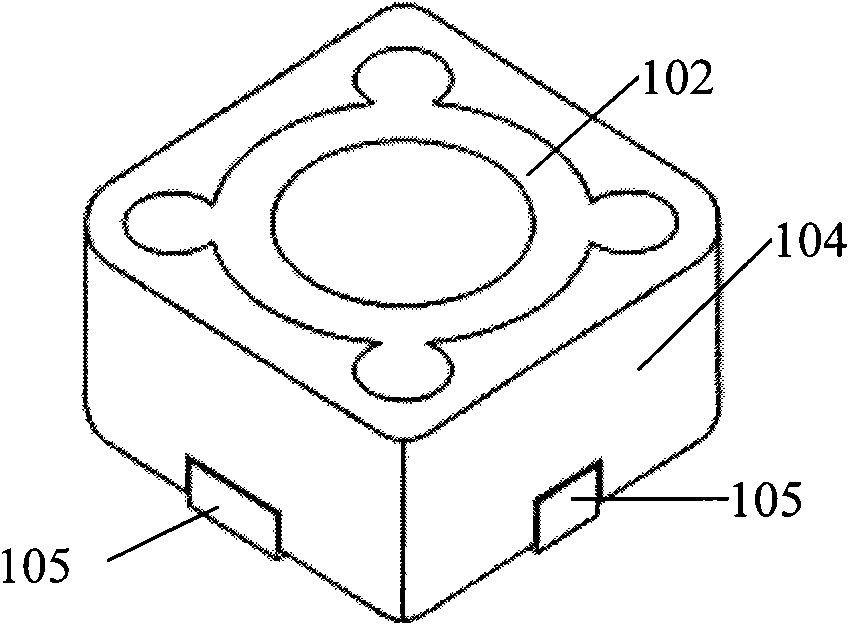

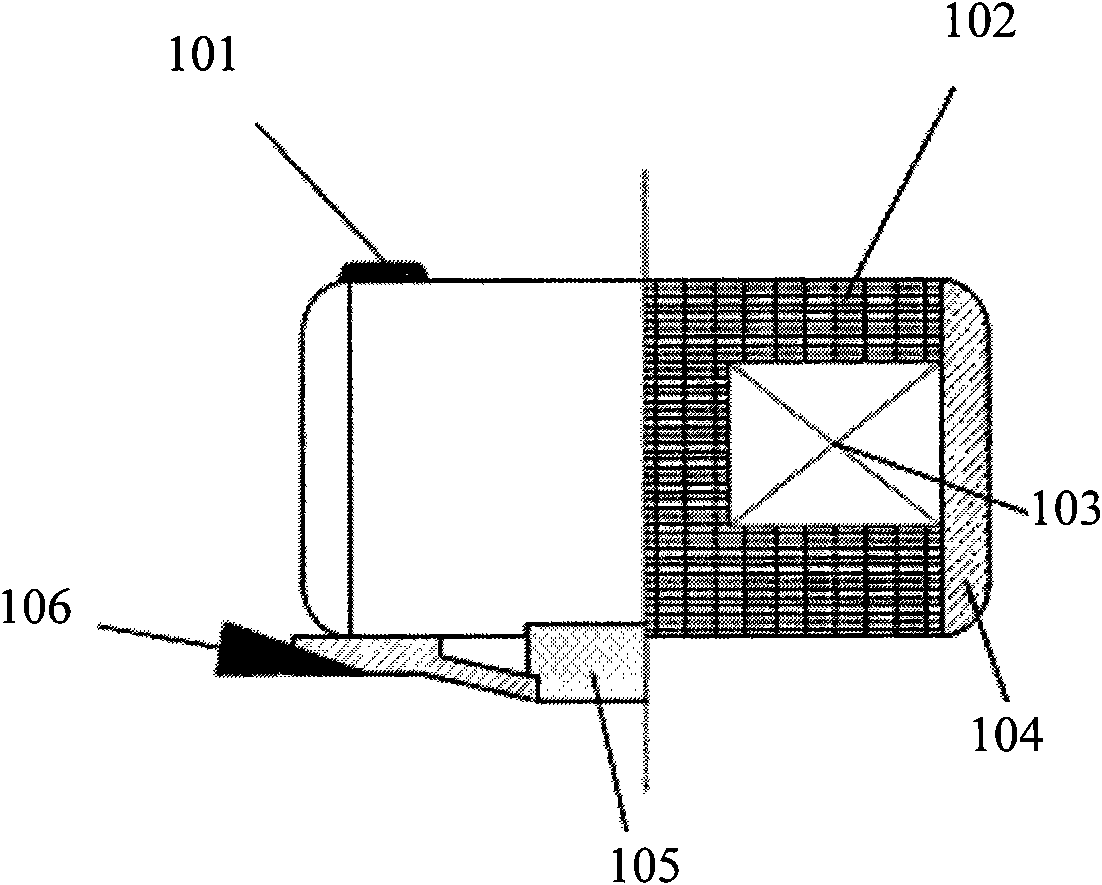

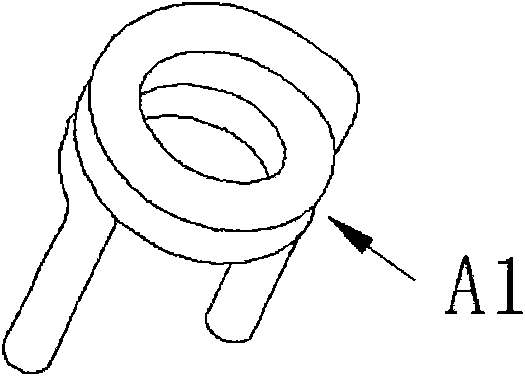

[0050] The patch type power inductor of the present invention includes a magnetizer and an enameled wire coil, wherein the coil includes a main body and an extension part, the magnetizer and the coil are integrally formed, and the material constituting the magnetizer is tightly filled in the The inside of the coil main body is tightly wrapped on the outside of the coil main body; the extension of the coil protrudes out of the magnetic conductor to form the electrodes of the inductor, and the electrodes are welded with the magnetic conductor. Electrode end piece. Preferably, the extension part is a flat structure, protrudes from opposite side surfaces of the magnetic conductor respectively, and is respectively bent to be close to the bottom surface of the magnetic conductor. The detailed manufacturing process and product structure are detailed below.

[0051] 1. Preparation of magnetic conductor powder

[0052] Among the present invention, the magnetizer mainly consists of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com